Steam generator tube, method of manufacturing the same and once-through steam generator

一种蒸汽发生器、形式的技术,应用在内型面的蒸汽发生器管领域,能够解决螺旋带得不到冷却、阻挡、不适用运行条件等问题,达到小压力损失的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

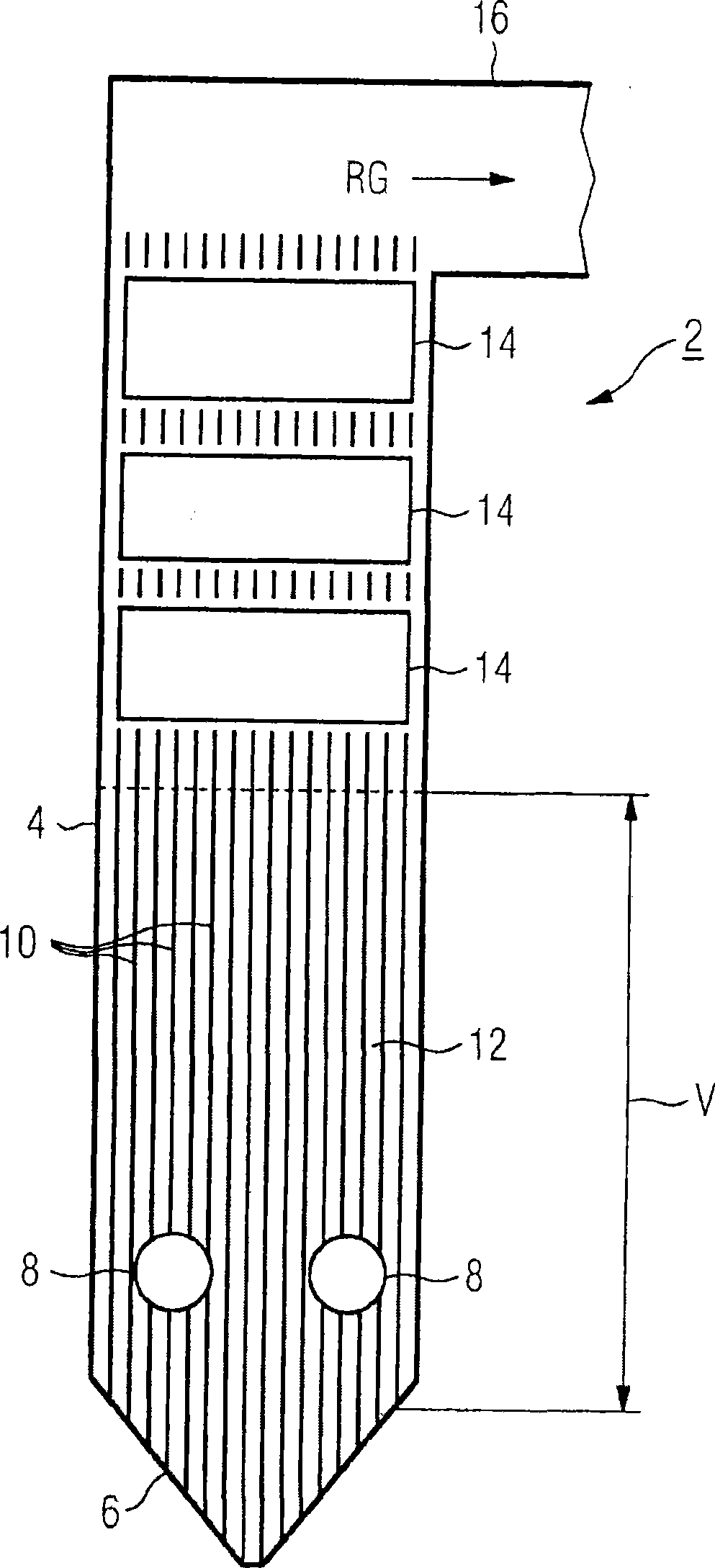

[0029] exist figure 1 A straight-through steam generator 2 with a rectangular cross section is schematically shown in , the vertical gas channel of which is formed by a surrounding wall or combustion chamber wall 4 , which transitions at the lower end into a bucket-shaped bottom 6 .

[0030] A number of burners for the fuel in openings 8 (only two are visible in the figure) are arranged in the combustion chamber wall 4 composed of steam generator tubes 10 in the ignition region V of the gas duct. The vertically arranged steam generator tubes 10 are gas-tightly welded to one another in the ignition region V to form the evaporator heating surface 12 .

[0031] Above the ignition region V of the air duct is a convective heating surface 14 . Located above it is a flue outflow channel 16 through which flue gas RG produced by burning fossil fuel leaves the vertical flue. The flow medium flowing in the steam generator tube 10 is heated by the radiant heat of the burner flame and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com