Totally-enclosed examination and repair process with pressure for feedwater piping

A water supply pipeline, fully enclosed technology, applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of heavy workload and difficulty, unable to overcome hydraulic shock, difficult to control the state, etc., to achieve quality and safety Improve performance, eliminate leakage of water medium, and increase safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

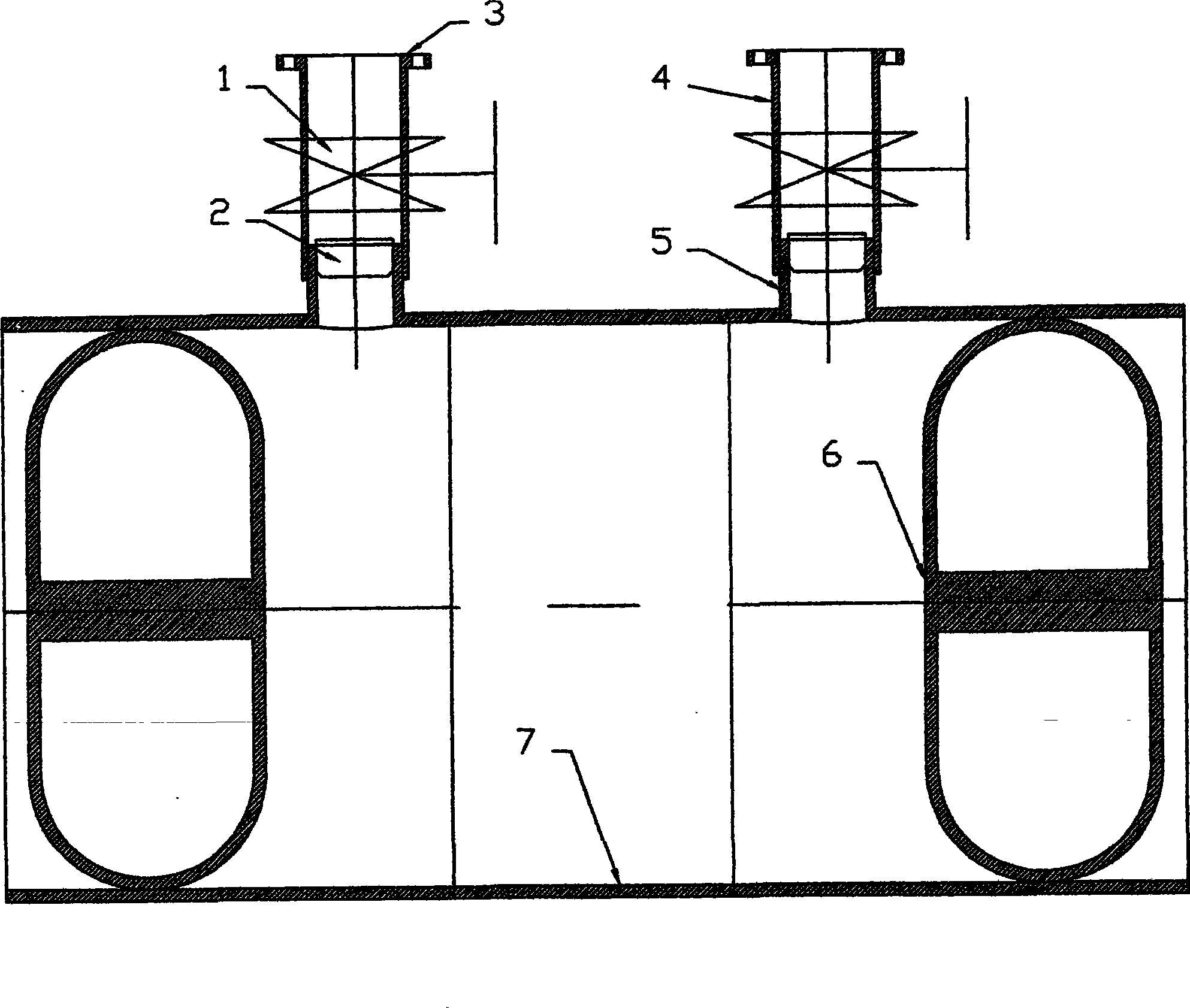

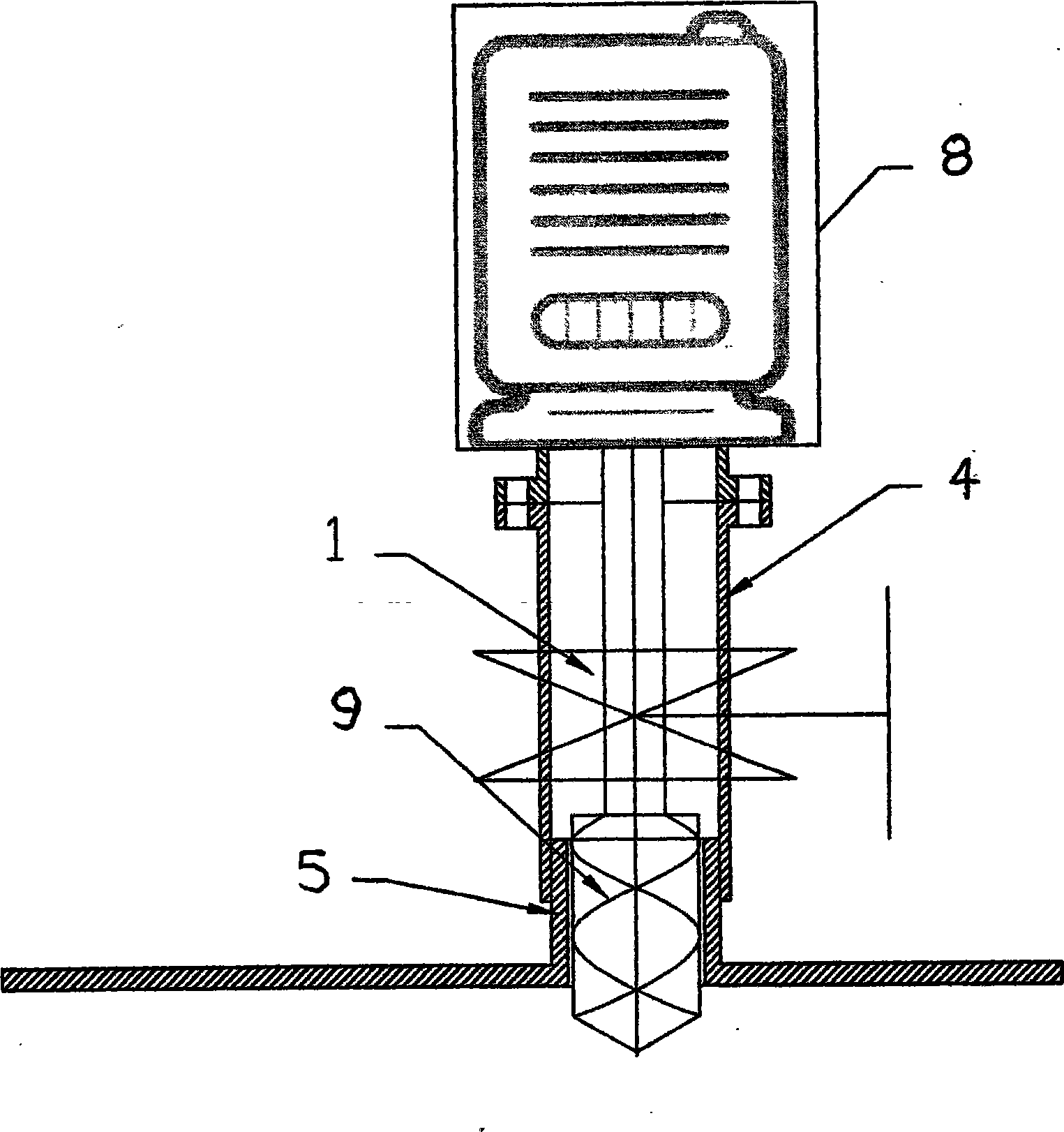

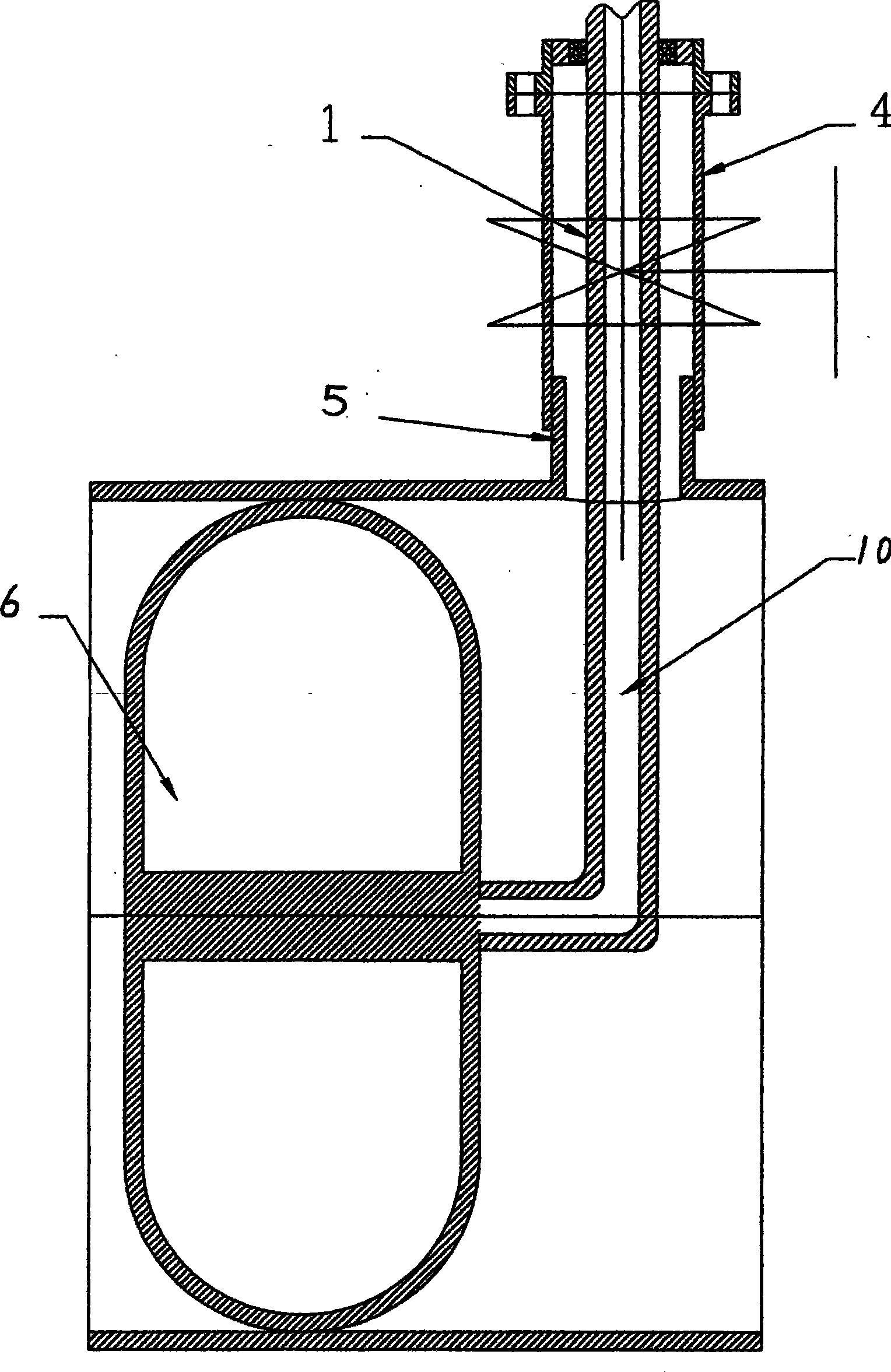

[0022] The fully-enclosed pressurized maintenance process of the water supply pipeline of the present invention is realized in this way, using compressed air to expand the rubber balloon on the inner wall of the pipeline to form a sealed cross section to stop the leaking water from the pipeline, and then carry out the operation. After the operation is completed, Release the compressed air in the balloon, the volume of the balloon will shrink under the action of its own elasticity, and then it can be taken out from the process hole, and the pipeline operation can be resumed after the process hole is closed.

[0023] Technical performance and features: sealing pressure ≤ 0.1MPa; the maximum expansion diameter reaches 1200mm; the diameter of the process hole is controlled below ∮80mm; high-pressure air is used to inflate the balloon, and corresponding system control devices such as safety valve, control valve and pressure gauge are required; The material of the balloon is rubber, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com