High-efficiency coal-saving burning additive

An additive and high-efficiency technology, applied in the field of coal-fired additives, can solve problems such as environmental pollution, insufficient coal combustion, and shortage of coal resources, and achieve the effects of improving furnace efficiency, reducing the generation of harmful substances, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

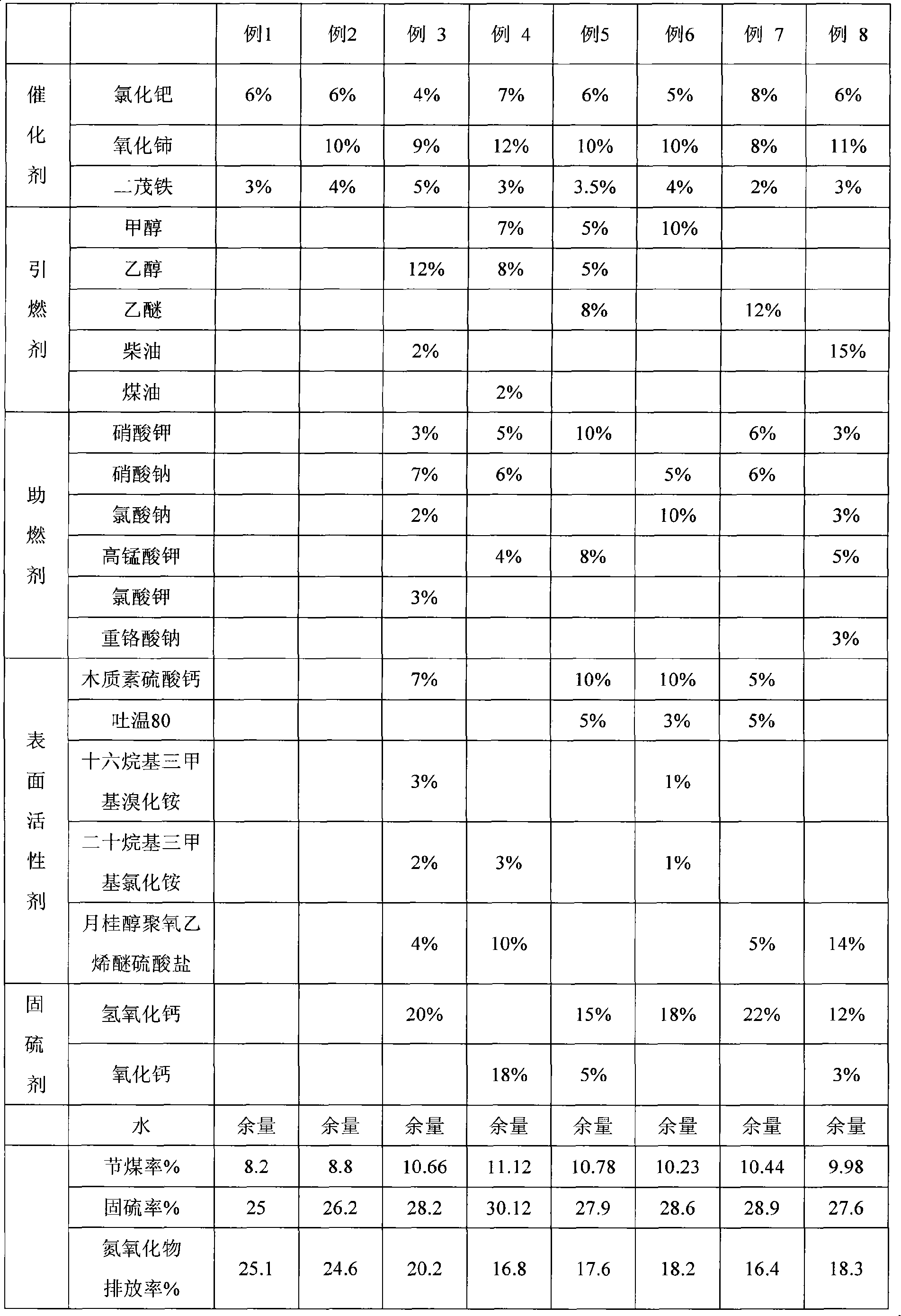

[0029] Specific embodiments of the present invention are shown in Table 1.

[0030] Table 1 Raw material composition (weight percent) of high-efficiency coal-saving combustion-supporting additives

[0031]

[0032] Get the raw material in each embodiment and prepare as follows:

[0033] a. Add sulfur-fixing agent and water in No. 1 reaction kettle, stir for 25-40 minutes, and dissolve it into a solution;

[0034] b. Add igniter, accelerant and water to the No. 2 reaction kettle, stir for 30-45 minutes, and heat to 50°C to make it a solution;

[0035] c. Add catalyst and water into No. 3 reaction kettle, stir for 25-40 minutes, heat to 50°C, and make it into a solution;

[0036] d. All the solutions obtained in the No. 1, No. 2 and No. 3 reaction kettles are added to the No. 4 reaction kettle, and the surfactant is added in proportion, and the mixture is slowly stirred until the mixture is uniform.

[0037] The high-efficiency coal-saving combustion-supporting additive of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com