Technique for producing oil products by fischer-tropsch synthesis

A technology of Fischer-Tropsch synthesis and process method, applied in the petroleum industry, recovery of liquid hydrocarbon mixtures, etc., can solve the problems of increasing the design diameter of the reactor, reducing the partial pressure of the effective gas reaction, and increasing the cycle power consumption, so as to save investment Effects of cost and operating energy consumption, improvement of effective gas composition, and improvement of space-time yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

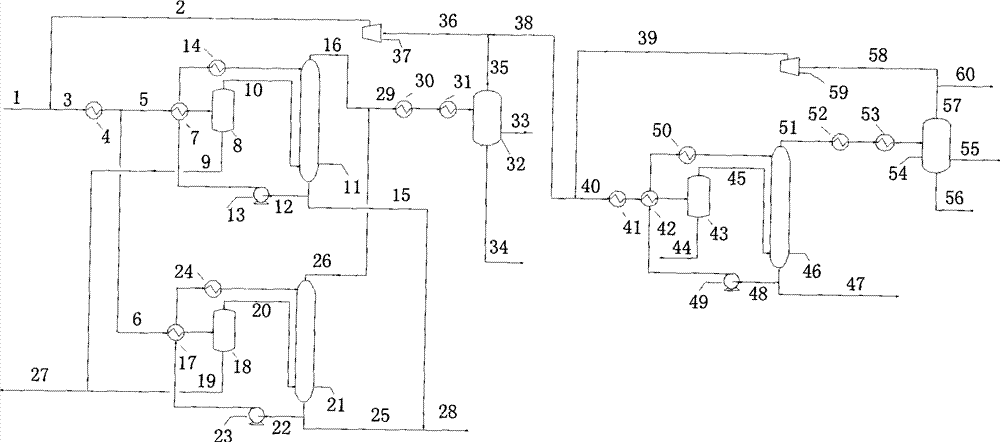

[0036] The main feature of this embodiment is that two-stage Fischer-Tropsch synthesis is adopted, wherein two first-stage Fischer-Tropsch synthesis reactors are connected in parallel, and the second-stage Fischer-Tropsch synthesis reactor is single. Such as figure 1 As shown, the first-stage Fischer-Tropsch synthesis reactor is two parallel reactors, and the second-stage Fischer-Tropsch synthesis reactor is a single one. The primary and secondary Fischer-Tropsch synthesis are both low-temperature Fischer-Tropsch synthesis, using a slurry bed reactor.

[0037] The temperature of fresh syngas 1 is 40°C, the pressure is 2.9MPaG, and the flow rate is 780000Nm 3 / h, the molar composition is H 2 : 0.617, CO: 0.374, CO 2 : 0.004, Ar: 0.001, CH 4 :0.001,N 2 : 0.004. The fresh synthesis gas 1 is mixed with the exhaust gas 2 of the first-stage synthesis cycle. After the mixed gas stream 3 is preheated by the heat exchanger 4, it is divided into two streams 5 and 6 on average, and...

Embodiment 2

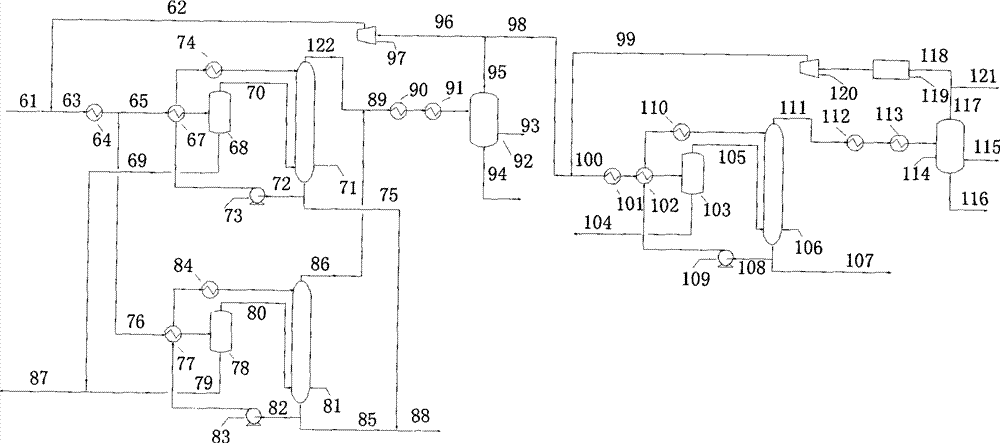

[0047] The difference between the process of Example 2 and that of Example 1 is that the circulating tail gas of the secondary synthesis reactor is decarburized and then recycled back to the inlet of the secondary synthesis reactor, and the rest of the process configurations are the same. Such as figure 2 As shown, the first-stage Fischer-Tropsch synthesis reactor is two parallel reactors, and the second-stage Fischer-Tropsch synthesis reactor is single, but the tail gas of the second-stage Fischer-Tropsch synthesis is recycled to the second-stage synthesis reactor after decarburization. The primary and secondary Fischer-Tropsch synthesis are both low-temperature Fischer-Tropsch synthesis, using a slurry bed reactor. The secondary gas circulation ratio remains the same as in Example 1, and the reactor size is also consistent.

[0048] The pressure, flow rate and gas composition of the fresh syngas are the same as in Example 1.

[0049] Fresh synthesis gas 61 is mixed with p...

Embodiment 3

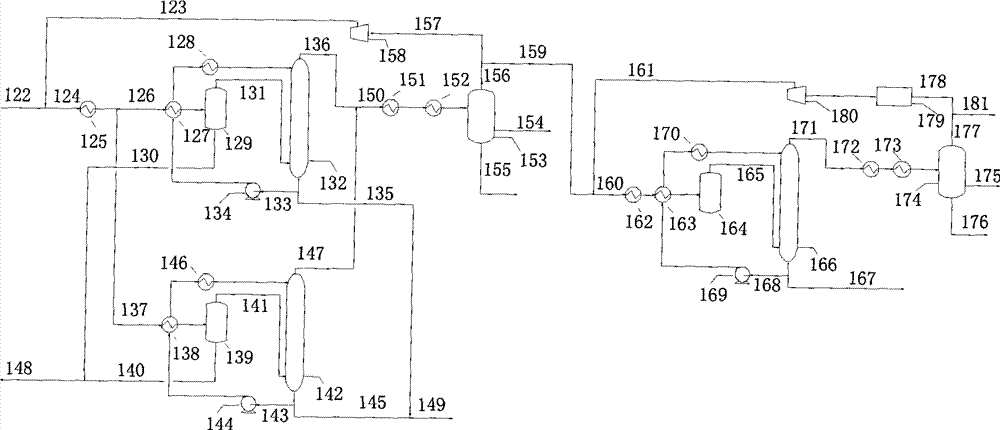

[0059] Embodiment 3 has also adopted the process of secondary tail gas decarburization, and the difference from Example 2 is that the secondary Fischer-Tropsch synthesis adopts a high-temperature Fischer-Tropsch synthesis process, and the secondary Fischer-Tropsch synthesis reactor adopts a fluidized bed reactor. The scheme of high-level synthetic products is also different from the previous two cases. Such as image 3 As shown, the first-stage Fischer-Tropsch synthesis reactor is two parallel reactors, the second-stage Fischer-Tropsch synthesis reactor is single, and the tail gas of the second-stage Fischer-Tropsch synthesis is decarburized and then recycled back to the second-stage synthesis reactor. For low-temperature Fischer-Tropsch synthesis, a slurry bed reactor is used; however, the second-stage Fischer-Tropsch synthesis is a high-temperature Fischer-Tropsch synthesis process, and the reactor is a fluidized bed reactor, but the size of the second-stage reactor is the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com