Large medical apparatus aluminium alloy casting stable filling method

A technology for aluminum alloy castings and medical equipment, which is applied in the control of pouring molten metal from a casting ladle, casting equipment, metal processing equipment, etc. To achieve the effect of stable filling, small scouring effect, and stable filling process

Active Publication Date: 2009-03-11

JIANGSU HONGDE SPECIAL PARTS CO LTD

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] When the pouring time is too short, the pouring speed is fast, which will cause the filling to be unstable, resulting in the appearance of air entrainment and turbulent flow, resulting in the occurrence of secondary

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

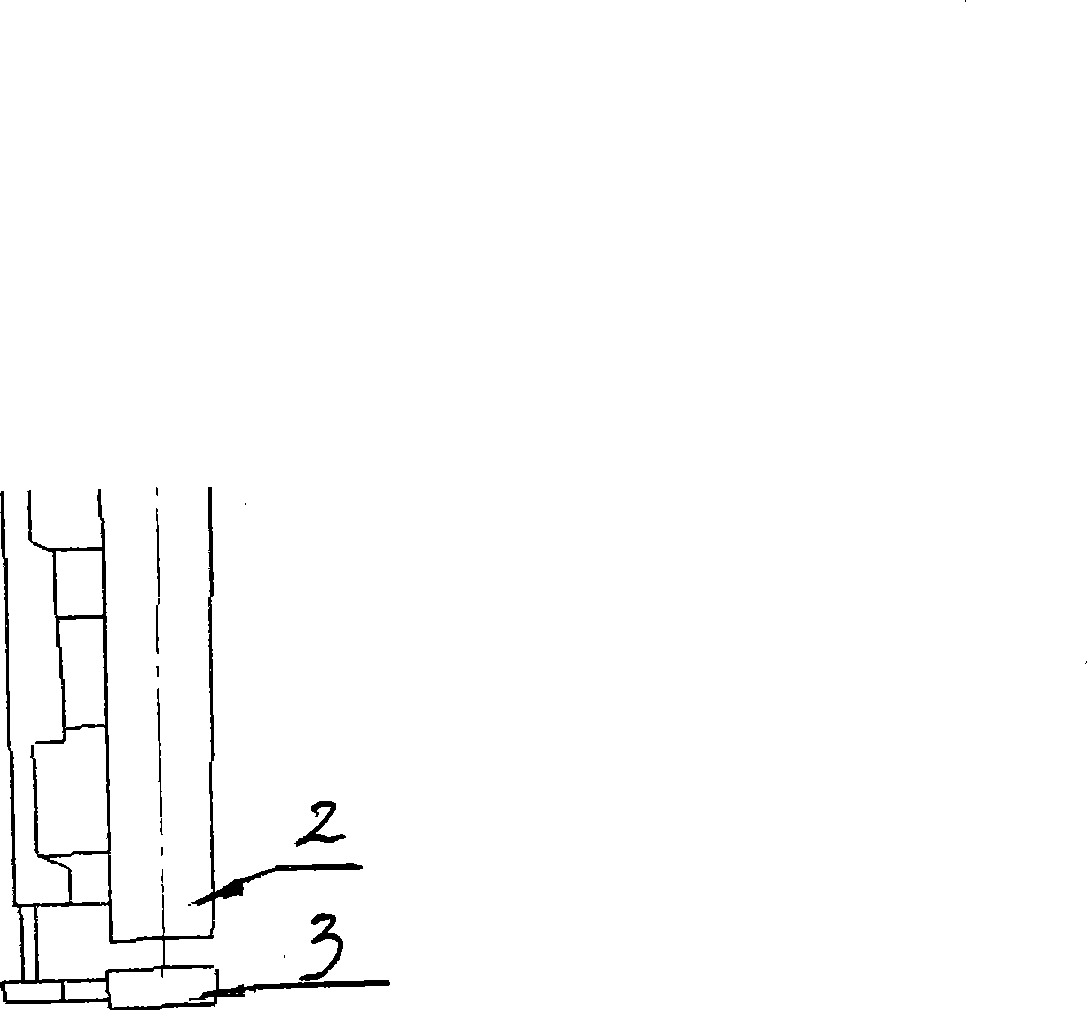

[0012] A method for stably filling large aluminum alloy castings for medical devices, comprising pouring in a pouring system, and installing a filter 1 at the entrance of the runner of the pouring system to block slag and buffer; the pouring time is 58 seconds; The pouring temperature is 725°C. The riser 2 and the runner 3 of the gating system are separated.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a steady filling method for an aluminum-alloy cast of a large medical apparatus, the method includes carrying out pouring in a pouring gate system and arranging a filter which plays the roles of baffling slag and cushion at the inlet of a transverse pouring gate in the pouring system; the pouring time is 58 seconds and the pouring temperature is 725 DEG C. The method leads the aluminum-alloy cast to be steadily filled and reduces the oxide inclusion.

Description

Technical field: [0001] The invention relates to a mold filling method for aluminum alloy castings. Background technique: [0002] Large-scale aluminum alloy castings are prone to defects such as secondary oxidation inclusions during the pouring process, resulting in scrapping. Therefore, how to achieve smooth forming of aluminum alloy and reduce secondary oxidation inclusions is a key issue in aluminum alloy casting technology. [0003] When the pouring time is too short, the pouring speed is fast, which will cause the mold filling to be unstable, resulting in air entrainment and turbulent flow, resulting in secondary oxidation inclusion defects. The aluminum liquid coming down from the sprue is relatively fast, and it will turn suddenly when it reaches the bottom of the sprue, which is very easy to generate turbulence and air entrainment. Excessively high pouring temperature will seriously oxidize the molten aluminum, and oxides will be produced before pouring, forming o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B22D37/00B22D35/04

Inventor 杨金德

Owner JIANGSU HONGDE SPECIAL PARTS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com