Deep drawing method of magnesium alloy tailor welded blanks

A magnesium alloy and tailor welded blank technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of low strength and rigidity, unfavorable electronic shielding effect, difficult plastic forming and other problems of die castings, so as to avoid cracking or The effect of weld offset, avoiding cracking or severe weld offset, and uniform deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

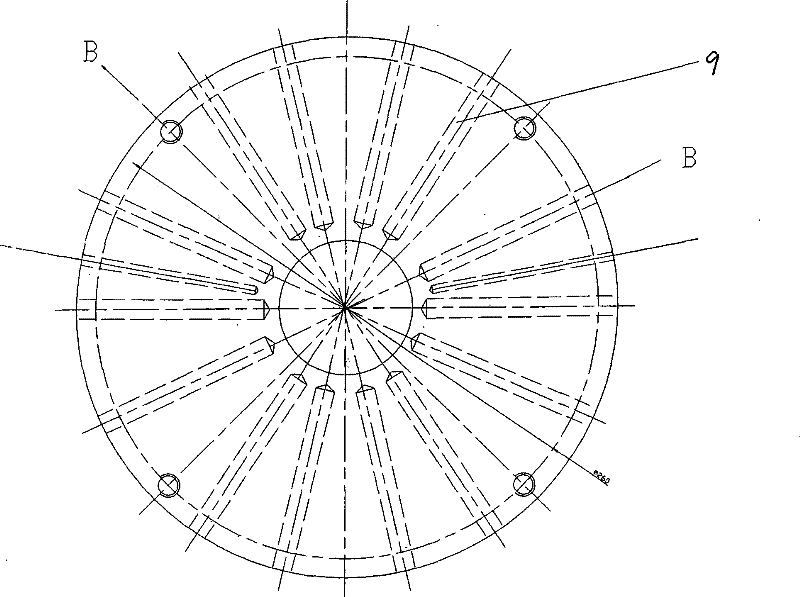

[0027] A magnesium alloy tailored welded blank drawing forming device according to the present invention comprises an upper template 1, a drawing punch fixing plate 2, a drawing punch 3, a blank holder 4, a blank 5, a drawing die 6, and a heating plate 7. The lower template 8, wherein the heating plate 7 is located below the drawing die 6, and a plurality of electric heating rods 9 are respectively inserted on the drawing die 6 and the blank holder 4. The device of the present invention has been disclosed and authorized, and the patent No. is ZL02144943.0, so the structure of the device is no longer described.

[0028] A method for deep drawing of magnesium alloy tailor welded blanks, comprising the following operations:

[0029] The deep drawing of AZ31 and AZ80 magnesium alloy tailored welded blanks is taken as an example to illustrate. Operation steps for deep drawing of AZ31 and AZ80 magnesium alloy tailored welded blanks:

[0030] 1) Blank preparation: the blank is weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com