Device and method for detecting contact type large-scale special-shaped glass outline based on rotating-rectilinear movements

A technology of linear motion and special-shaped glass, which is applied in the direction of measuring devices, instruments, etc., can solve the problems of large space occupied by equipment, high cost of making templates, and inability to query and modify product outline graphics to achieve high reliability and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

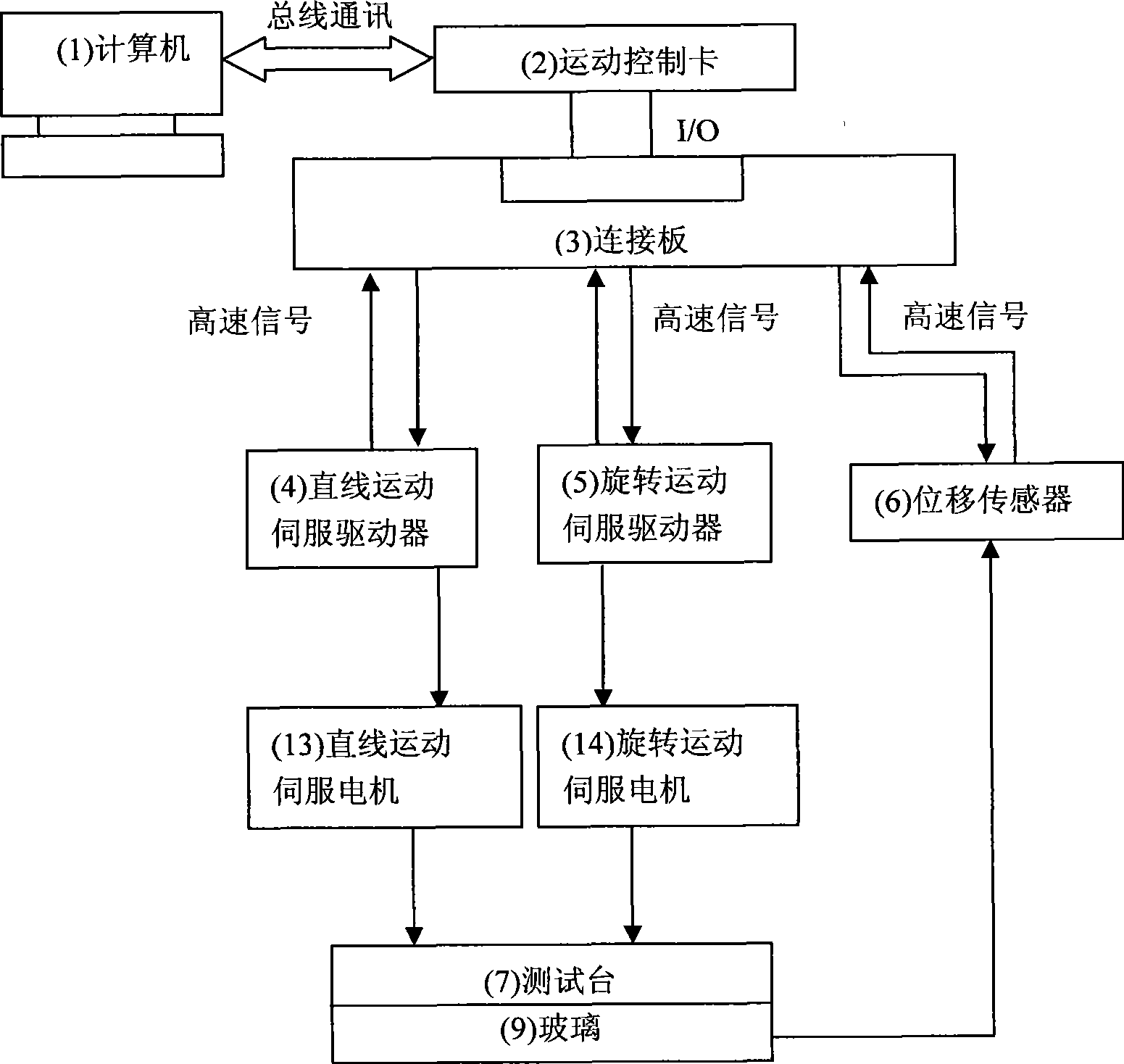

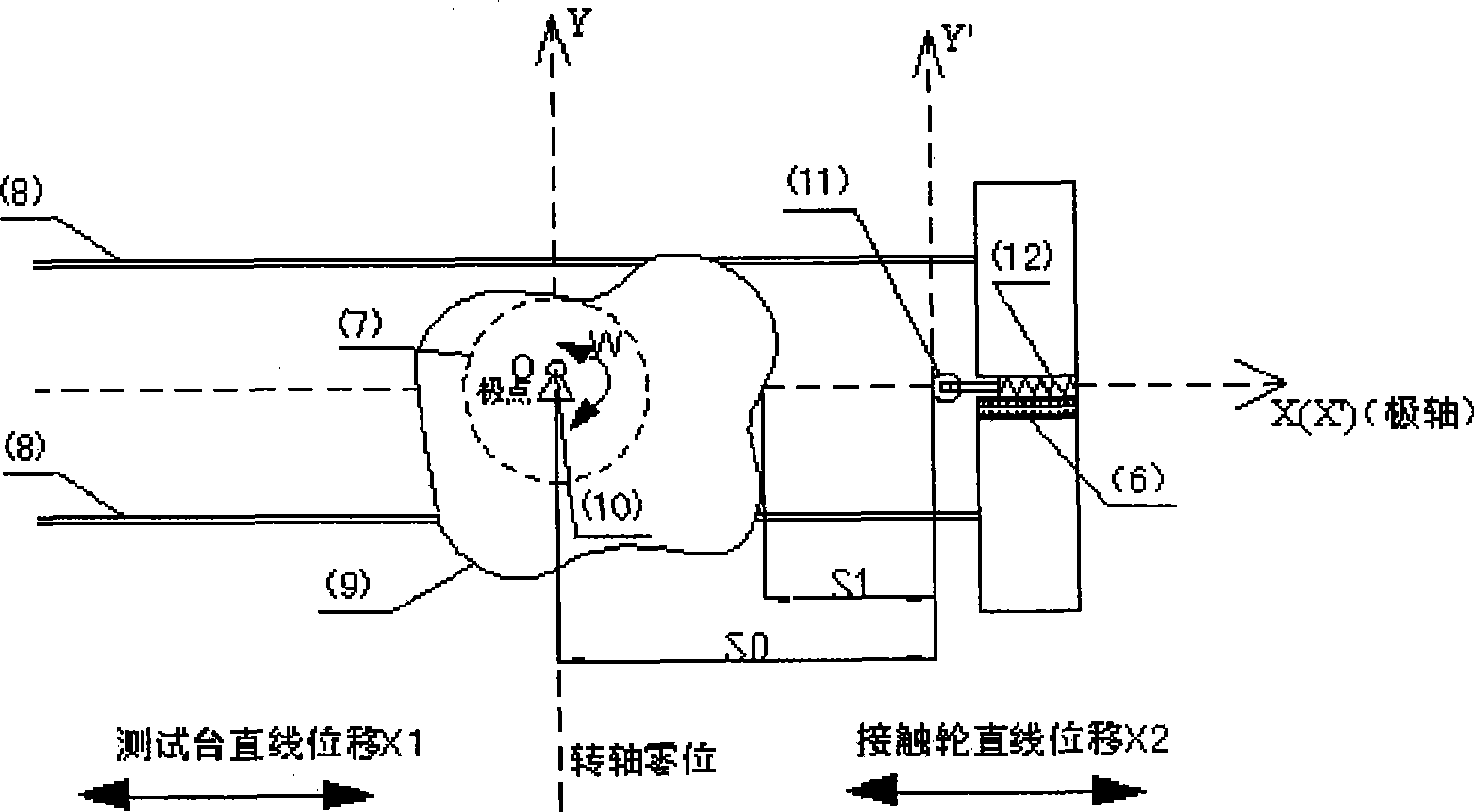

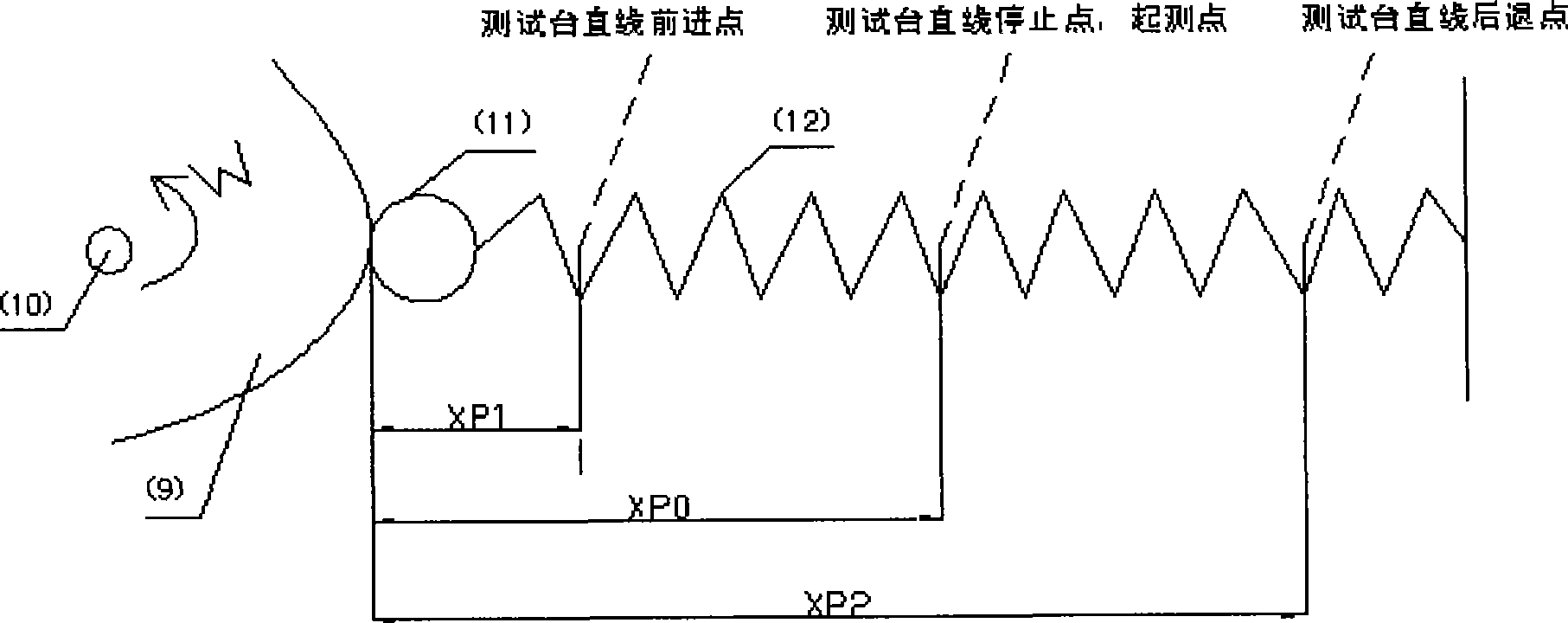

[0026] A specific embodiment of the present invention is described in detail as follows in conjunction with accompanying drawing: Refer to figure 1 , the contact-type large-scale special-shaped glass profile detection device based on rotation-linear motion, including a computer 1 and a test bench 7 for placing the measured special-shaped glass 9 and capable of linear motion and rotary motion; the computer 1 is connected to a motion control card 2 through a bus, and the motion control card 2 is connected to a connection board 3 through an I / O port, and the connection board 3 is connected to a linear motion servo driver 4, a rotary motion servo driver 5 and a displacement The sensors 6 are connected, the linear motion servo driver 4 is connected to the first servo motor 13 that drives the test bench 7 for linear motion, and the rotary motion servo driver 5 is connected to the second servo motor 14 that drives the test bench 7 for rotary motion , the displacement sensor 6 detects...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com