Fuel injection device, fuel injection system, and method for determining malfunction of the same

A technology of fuel injection device and fuel injection valve, which is applied in the direction of fuel injection device, fuel injection control, charging system, etc., and can solve problems such as difficult injection state and inaccessibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0027] The fuel injection device according to the present invention is installed, for example, on a common rail fuel injection system of an internal combustion engine of an automobile. For example, the present fuel injection device is used to directly inject high-pressure fuel into a combustion chamber in a cylinder of a diesel engine. The high-pressure fuel is, for example, light fuel oil, which has an injection pressure of 100 MPqa or more.

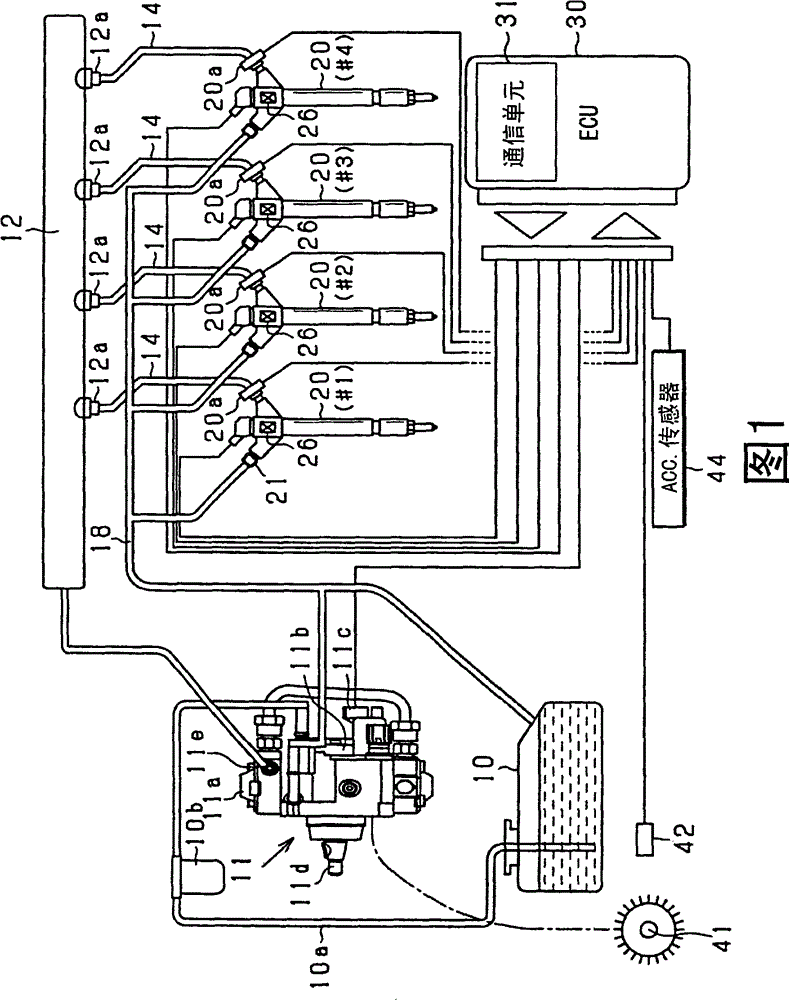

[0028] First, refer to figure 1 A common rail fuel injection system as an engine system in a vehicle according to this embodiment is described. In this embodiment, the engine is, for example, a multi-cylinder engine such as an inline four-cylinder engine. Specifically, the engine may be a four-stroke reciprocating diesel engine. In this engine, electromagnetic detectors are provided for the camshafts of the intake and exhaust valves as cylinder detection sensors in order to continuously determine the subject cylinder at that moment. ...

no. 2 example

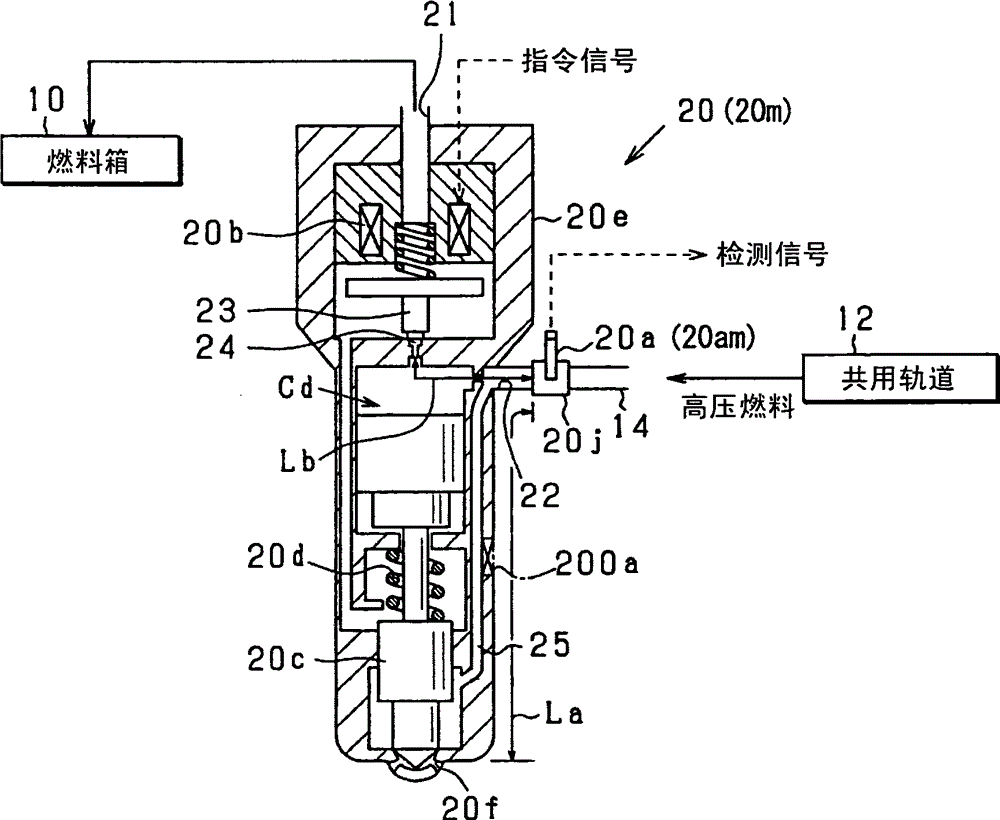

[0107] In this embodiment, a main injector 20m and a main sensor 20am are prepared, which are different from the injector 20 and the pressure sensor 20a which are objects to be detected. The main injector 20m and the main sensor 20am are equivalent to the main device. By inspection, the characteristics of the master device are measured in advance to obtain reference characteristics as a reference fluctuation pattern. The error of each characteristic of the injector 20 and the pressure sensor 20a with respect to the reference characteristic is measured. The measured errors are stored as individual difference information in the IC memory 26 serving as a storage unit (memory unit). The injector 20 and the pressure sensor 20a respectively correspond to devices to be detected.

[0108] The design structure of the main injector 20m is the same as the design structure of the injector 20 which is the object of inspection. The designed position of the pressure sensor with respect to...

no. 3 example

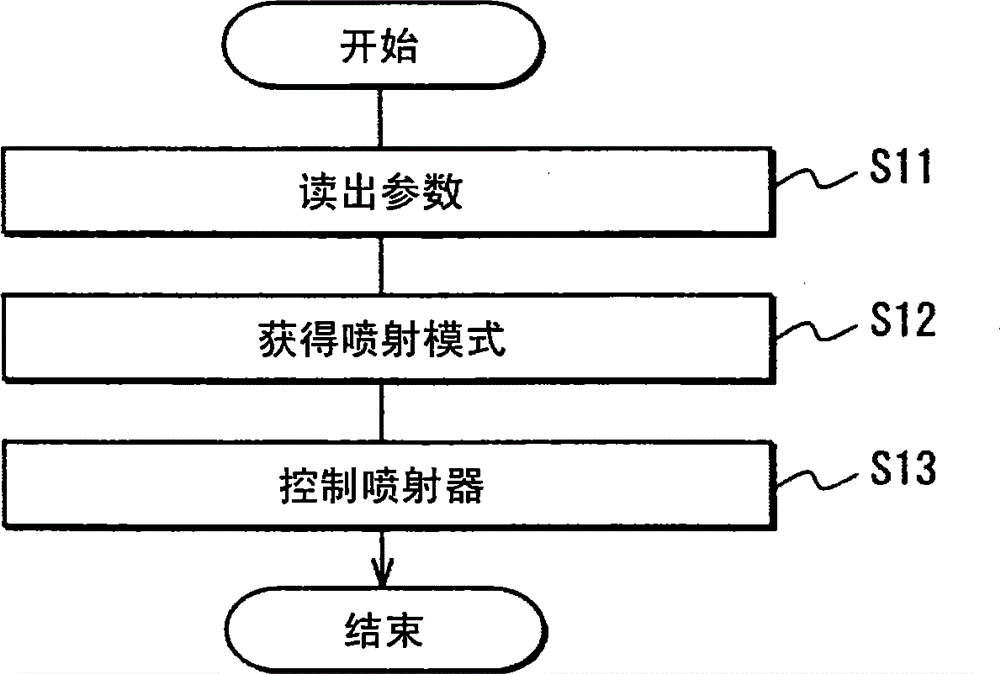

[0124] In this embodiment, in addition to the creation of the injection control map described in the second embodiment, a failure of the device to be detected is detected.

[0125] Used by measurement operators Figure 4 The measuring instrument 53 in the instrument performs processing related to this fault detection. Figure 14 This failure detection process is shown. This process may be performed at the factory, with the pressure sensor 20 a attached to the injector 20 and before the injector 20 is shipped. Alternatively, for example, after the injector 20 is dispatched to the market, this process may be performed in a repair shop where various repair work and inspections may be performed.

[0126] First, at M10 as the first measurement process, the command-injection time delay Tnom is measured as a reference invalid period of the main injector 20m equipped with the main sensor 20am as the main device. The command-injection time delay Tnom is the period from the power-on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com