Method for producing organic controlled release fertilizer by ammine acid method

A technology of controlled release fertilizer and amino acid method, which is applied in the direction of organic fertilizers, can solve the problems that have not been seen, and achieve the effect of improving the effectiveness, improving the utilization rate of chemical fertilizers, and accelerating the formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

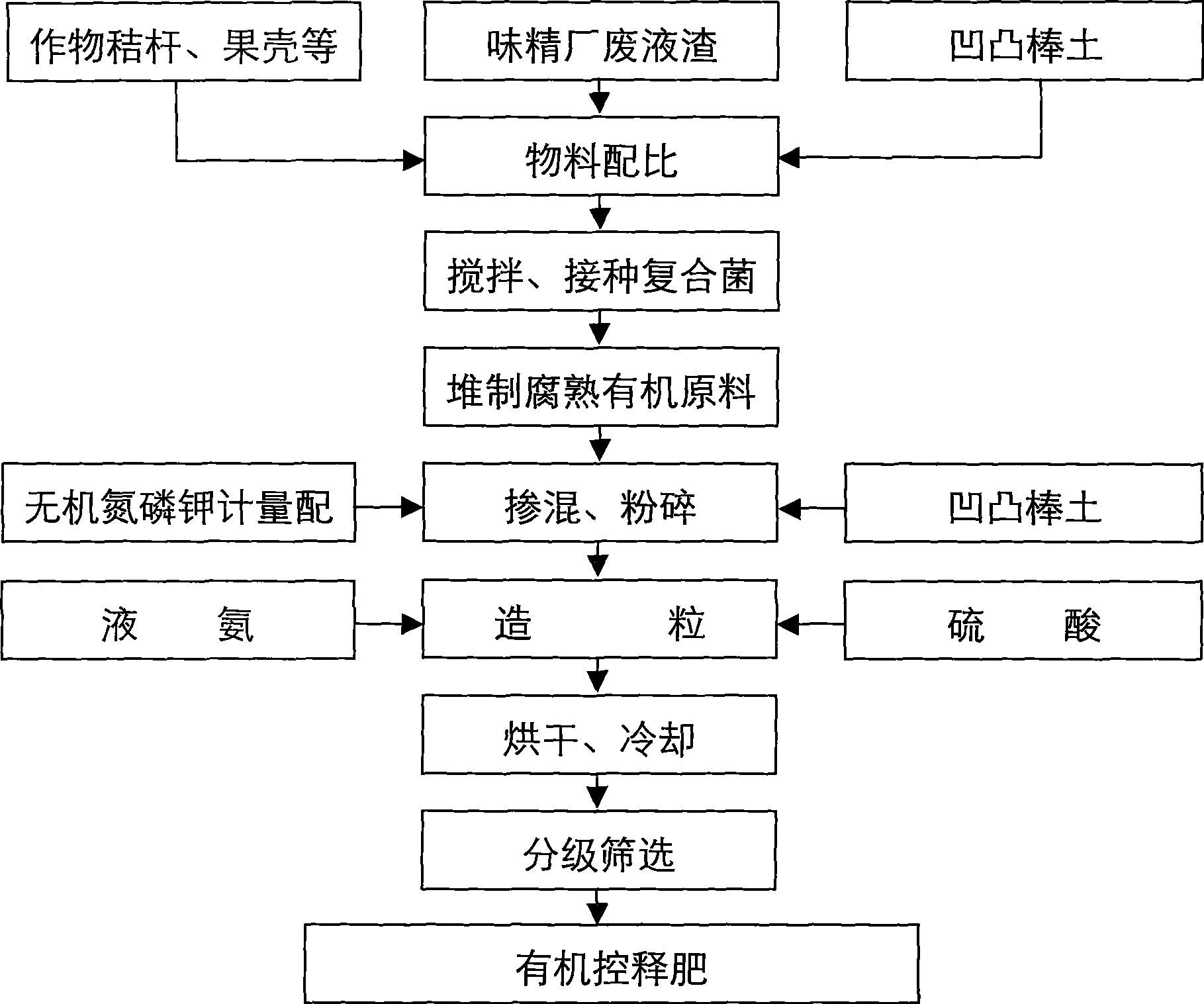

Image

Examples

Embodiment 1

[0028] The amino acid method is used to produce organic controlled-release fertilizer, and the following weights are taken:

[0029] 1,000 kg of monosodium glutamate residue; 3,000 kg of rice straw; 1,000 kg of peanut shell; 200 kg of attapulgite and mix them.

[0030] Take 0.6 kg of photosynthetic bacteria, 0.2 kg of actinomycetes, 0.4 kg of saccharomyces, 0.8 kg of phosphorus-solubilizing bacteria, 0.8 kg of potassium-solubilizing bacteria, and 1.2 kg of nitrogen-fixing bacteria. In the mixture of shell and attapulgite, compost and ferment for 7 days.

[0031] Take 1500 kilograms of monoammonium phosphate; 1750 kilograms of urea; 1500 kilograms of potassium chloride;

[0032] Add 2 kilograms of 98% concentrated sulfuric acid to the above mixture; 2 kilograms of liquid ammonia. Put it into a drum granulator to granulate, heat up at the same time, discharge after 20 minutes, cool, sieve, weigh, and pack.

[0033] The content of nitrogen, phosphorus and potassium in this pro...

Embodiment 2

[0035] The amino acid method is used to produce organic controlled-release fertilizer, and the following weights are taken:

[0036] 2,000 kg of monosodium glutamate residue; 5,000 kg of rice straw; 2,000 kg of peanut shell; 500 kg of attapulgite and mix them.

[0037] Take 1.2 kg of photosynthetic bacteria, 0.4 kg of actinomycetes, 0.8 kg of saccharomyces, 1.6 kg of phosphorus-solubilizing bacteria, 1.6 kg of potassium-solubilizing bacteria, and 2.4 kg of nitrogen-fixing bacteria. In the mixture of shell and attapulgite, compost and ferment for 7 days.

[0038] Take 3000 kilograms of diammonium phosphate; 3500 kilograms of urea; 3000 kilograms of potassium chloride; 500 kilograms of attapulgite and the above-mentioned fermented product are evenly mixed; pulverized.

[0039] Add 4 kilograms of 98% concentrated sulfuric acid to the above mixture; 4 kilograms of liquid ammonia. Put it into a drum granulator to granulate, heat up at the same time, discharge after 20 minutes, co...

Embodiment 3

[0042] Take the following weights of material:

[0043] 1,000 kg of monosodium glutamate waste residue; 2,500 kg of rice straw; 1,500 kg of peanut shell; 500 kg of attapulgite and mix them.

[0044] Take 0.6 kg of photosynthetic bacteria, 0.2 kg of actinomycetes, 0.4 kg of saccharomyces, 0.8 kg of phosphorus-solubilizing bacteria, 0.8 kg of potassium-solubilizing bacteria, and 1.2 kg of nitrogen-fixing bacteria. In the mixture of shell and attapulgite, compost and ferment for 6 days.

[0045] Get 3400 kg of ammonium phosphate; 2520 kg of potassium chloride; 4100 kg of ammonium chloride;

[0046] Add 20 kilograms of 98% concentrated sulfuric acid to the above mixture; 25 kilograms of liquid ammonia. Put it into a drum granulator to granulate, heat up at the same time, discharge after 20 minutes, cool, sieve, weigh, and pack.

[0047] The content of nitrogen, phosphorus and potassium in this product is ≥40%; the content of organic matter is ≥20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com