Method for manufacturing floor covering and floor covering manufacturing thereby

A ground covering and balancing layer technology, applied in floor coverings, chemical instruments and methods, floors, etc., can solve problems such as complex operations, achieve cost savings, reduce construction costs and time, and prevent manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

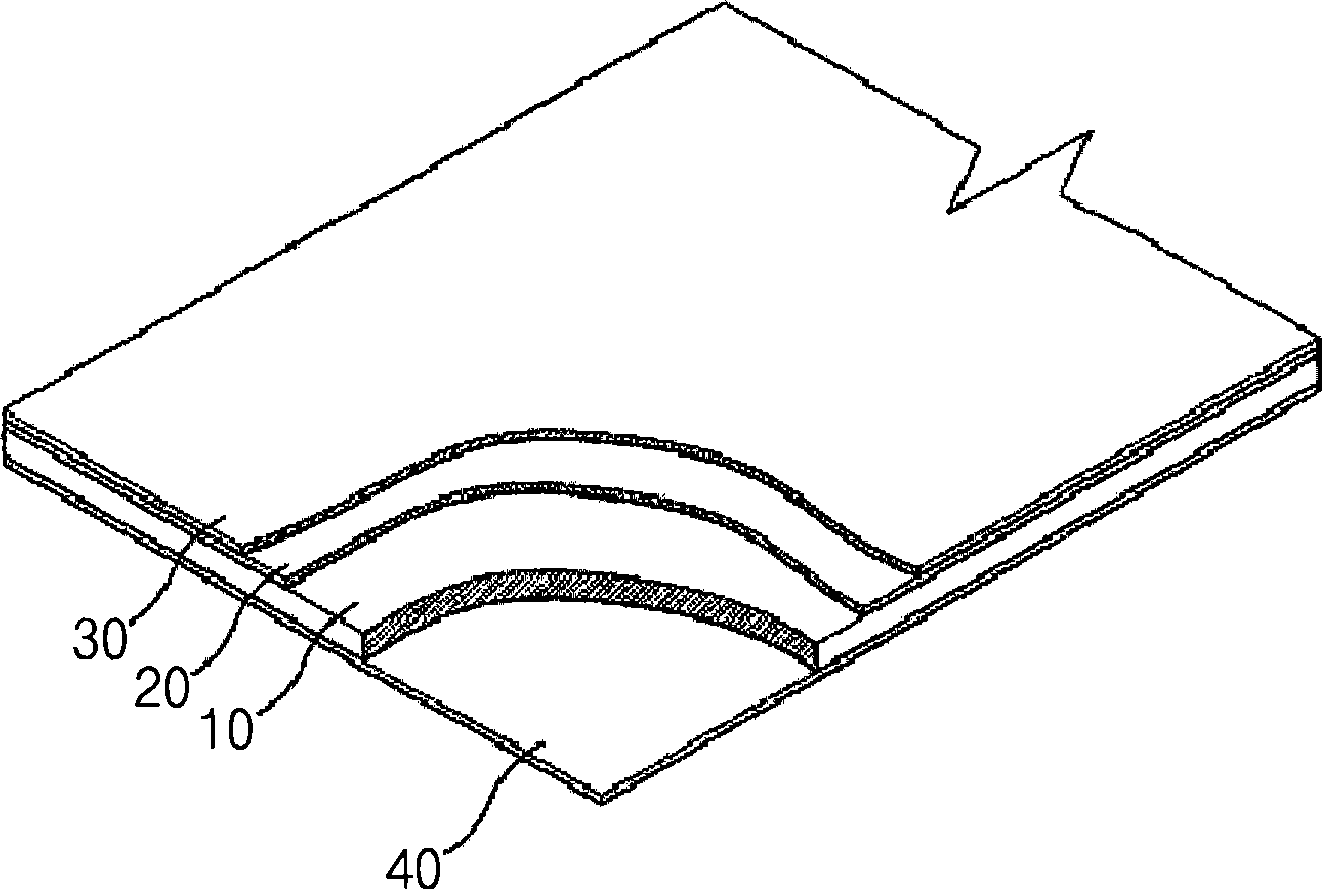

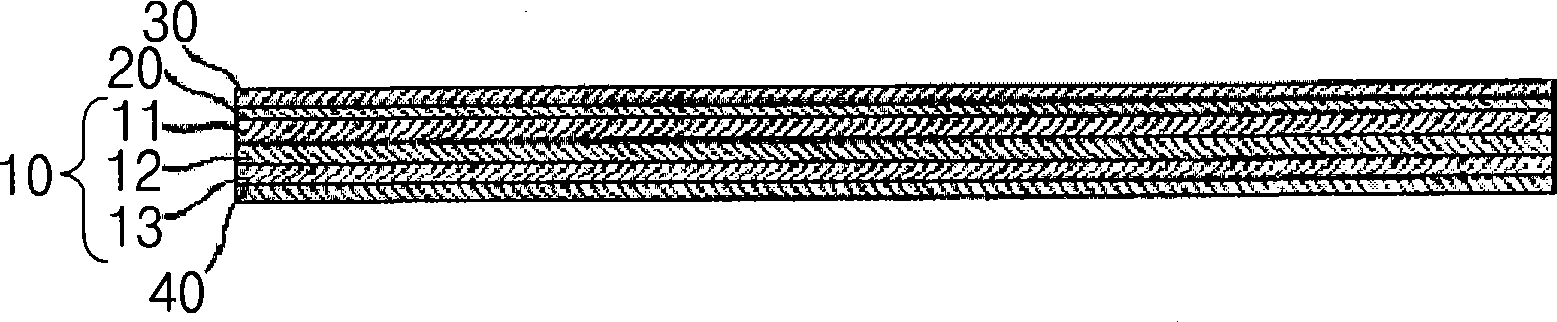

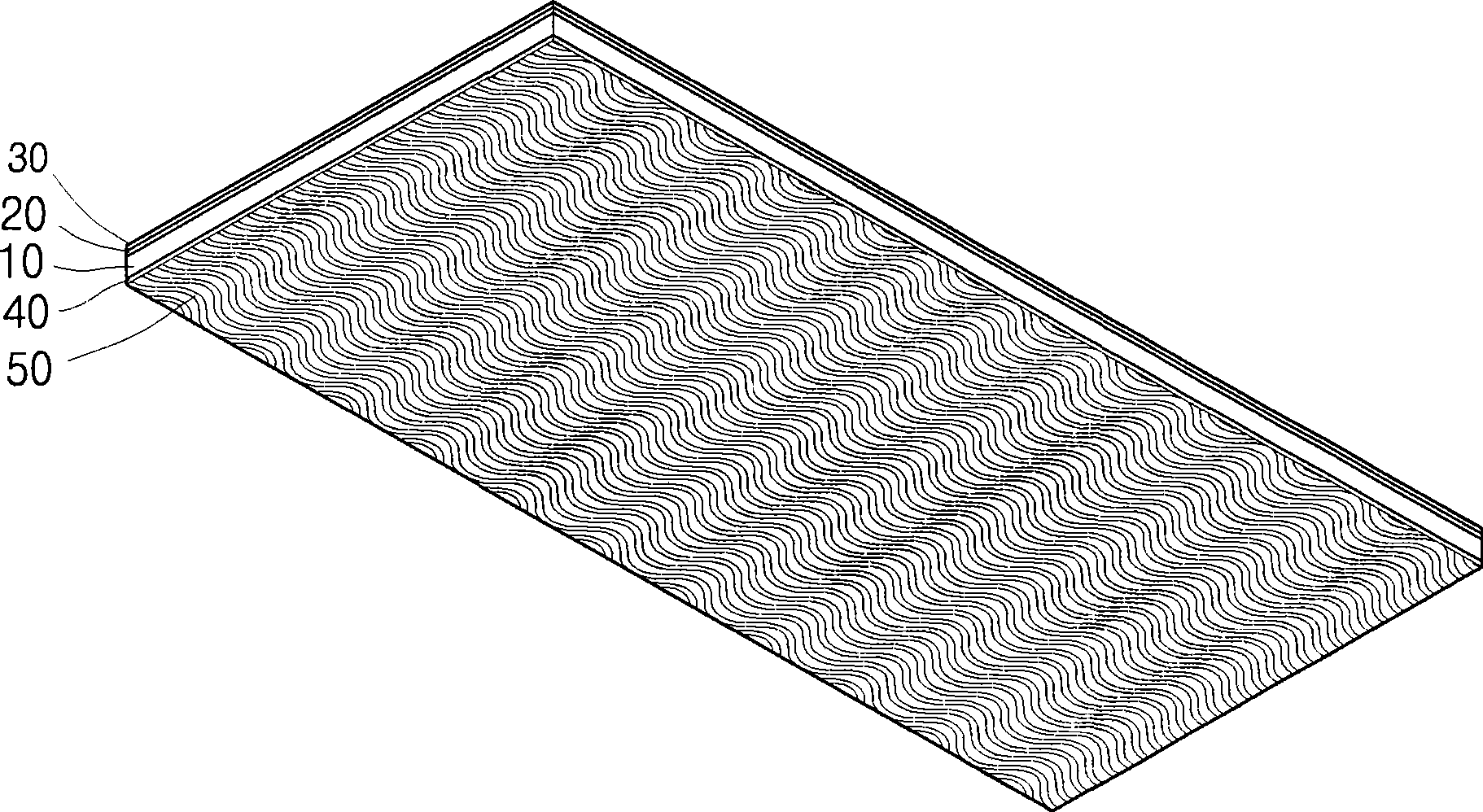

[0052] Manufacture the floor covering in the same manner as Comparative Example 1, and also perform the following additional process of forming a corrugated foam layer under the balance layer to manufacture the floor covering: 100 parts by weight of 1200-1700 The resin composition mixed with vinyl chloride, 120 parts by weight of dioctyl phthalate as a plasticizer and 10 parts by weight of calcium carbonate as a filler is subjected to mechanical foaming.

experiment example 1

[0054] The floor coverings manufactured in Comparative Example 1 and Example 1 were respectively placed on support plates made of cement mortar. , while applying a vertical load of 294 N, the ground covering was pulled at a tensile load rate of 294 N / s and an angle of 18°, and the maximum tensile load (N) was measured by resistance. The results are listed in Table 1.

[0055] Table 1

[0056] Slip performance (N) Comparative example 1 532 Example 1 664

[0057] As can be seen from Table 1, in Example 1 in which the foam layer was formed in the lowermost layer by the manufacturing method of the present invention, it was confirmed that the slipping performance was due to the high friction against cement mortar compared with the slipping type of Comparative Example 1. strength to improve.

experiment example 2

[0059] Sound insulation test

[0060] For the floor coverings manufactured in Comparative Example 1 and Example 1, impact was measured at Korea Noise and Vibration Technology Co., Ltd. according to KS F 2865, KS F 2863-1, KS F 2810-2 and KS F 2863-2 test methods Weighted reduction (ΔLW) of the sound pressure level. The results are listed in Table 2.

[0061] Table 2

[0062] △L W Comparative example 1 6 Example 1 8

[0063] As can be seen from Table 2, in Example 1 in which the foam layer was formed in the lowermost layer by the manufacturing method of the present invention, compared with the slippery type of Comparative Example 1, the weighted reduction of the impact sound pressure level was increased. From this it can be confirmed that the noise is significantly reduced when passing through the floor covering of the example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com