Machine for processing and squeezing pumping rod with three stations

A sucker rod and three-station technology, which is applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammering machinery, etc., to achieve the effects of saving processing time, fast processing speed and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

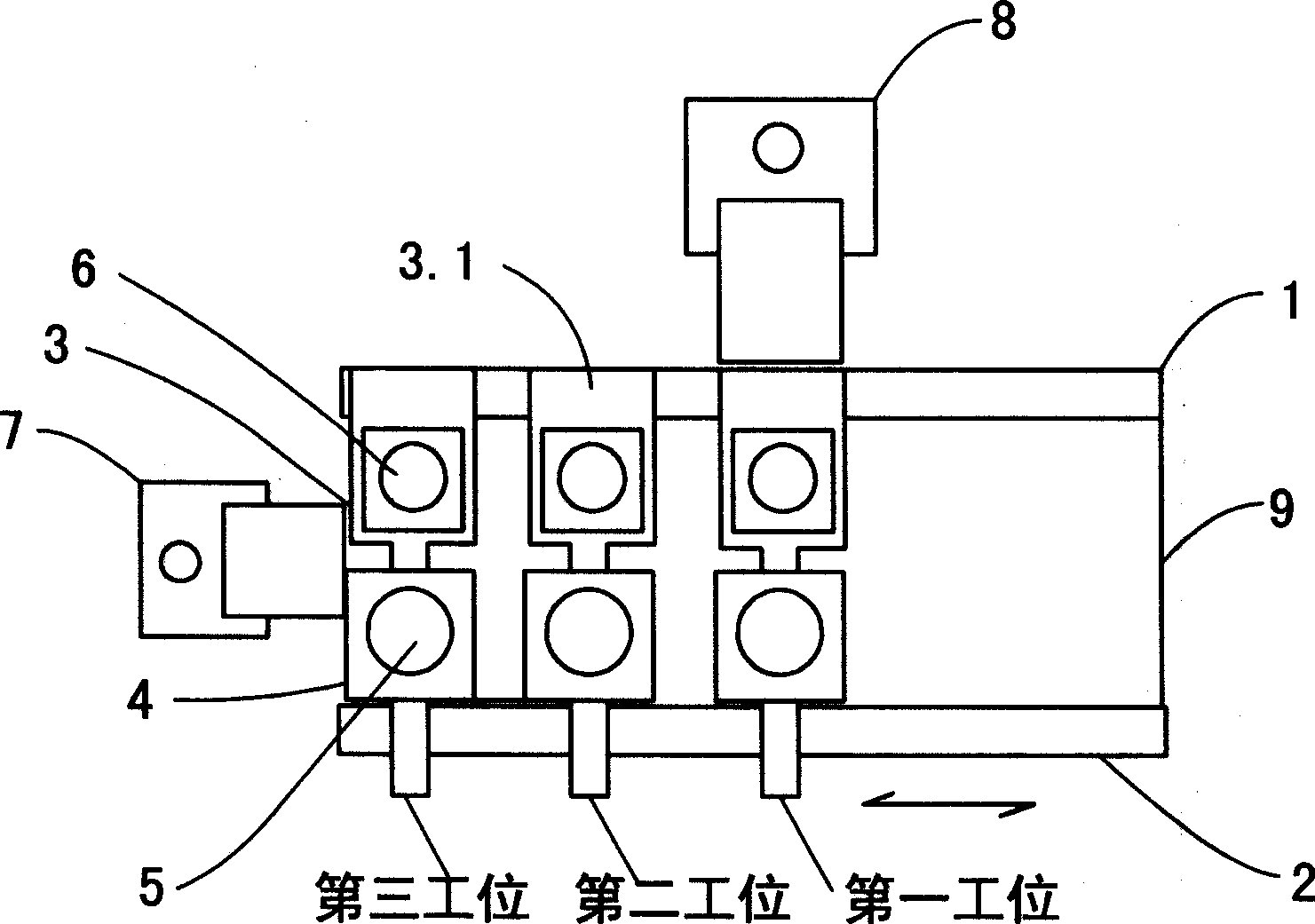

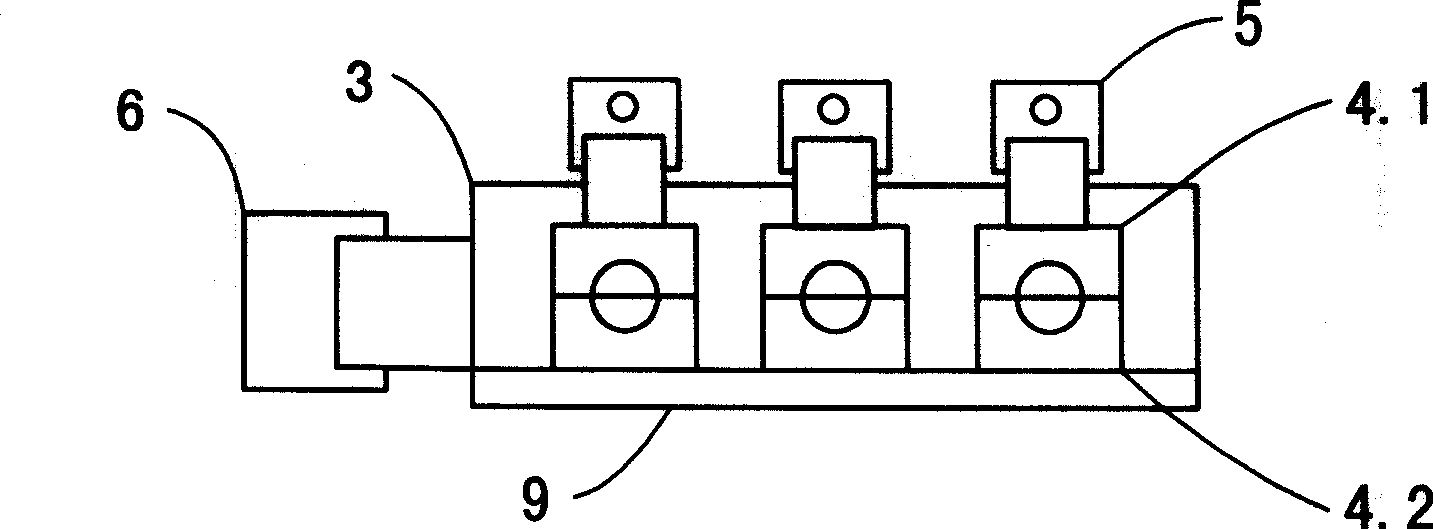

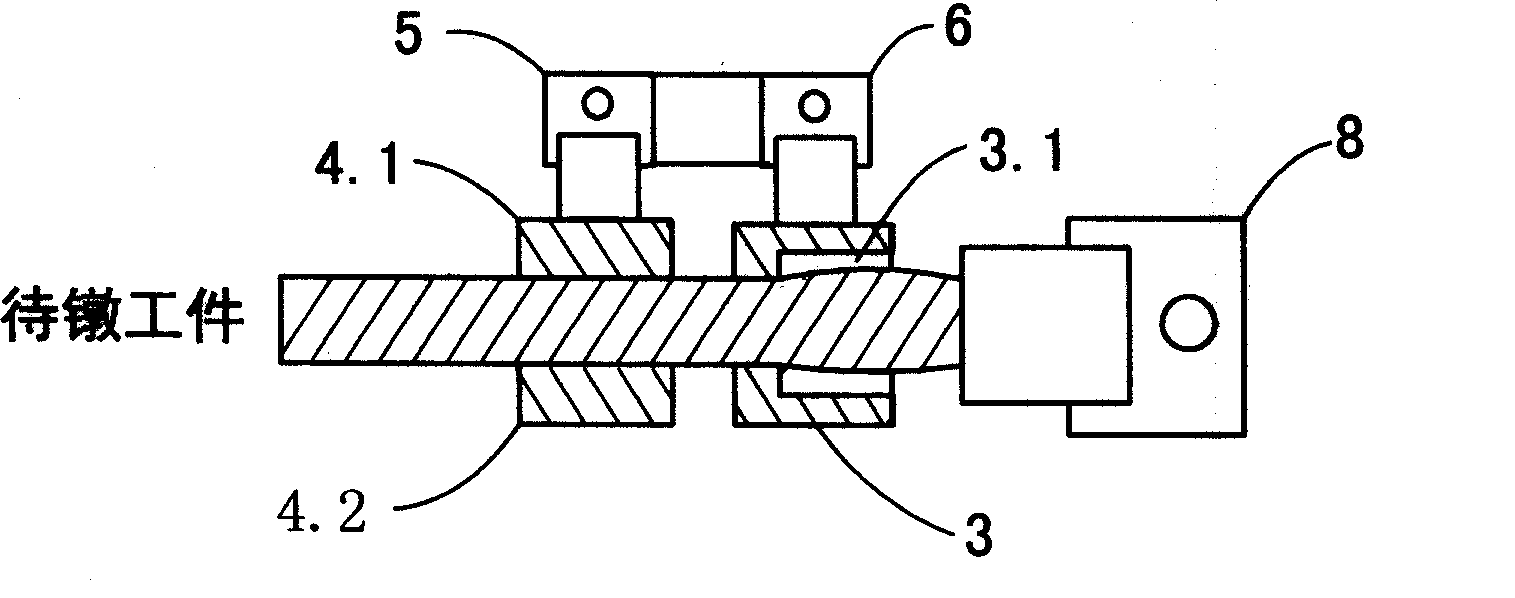

[0019] according to Figure 1~5 As shown, three sets of molds are combined into a mold group 3, the mold is an upper and lower half opening and closing structure, each set of molds is provided with a cavity 3.1, and the mold group is installed on the front baffle 1 and the rear baffle 2 in a sliding state And in the half groove that bottom plate 9 constitutes, be connected with mold group displacement oil cylinder 7 at the mold group side, be provided with upsetting extrusion oil cylinder 8 at the position corresponding to mold cavity of the front side of mold group. The clamp 4 has an upper and lower halves opening and closing structure, and is divided into a clamp upper plate 4.1 and a clamp lower plate 4.2. A mold opening and closing oil cylinder 6 and a clamper oil cylinder 5 are respectively connected to the upper half mold and the upper plate of the clamper. An upsetting oil cylinder 8 is arranged at the position corresponding to the die cavity on the front side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com