Vibration sensor

A vibration sensor and barrier technology, applied in the field of vibration sensors, can solve problems such as energy attenuation and reducing the sensitivity of condenser microphones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

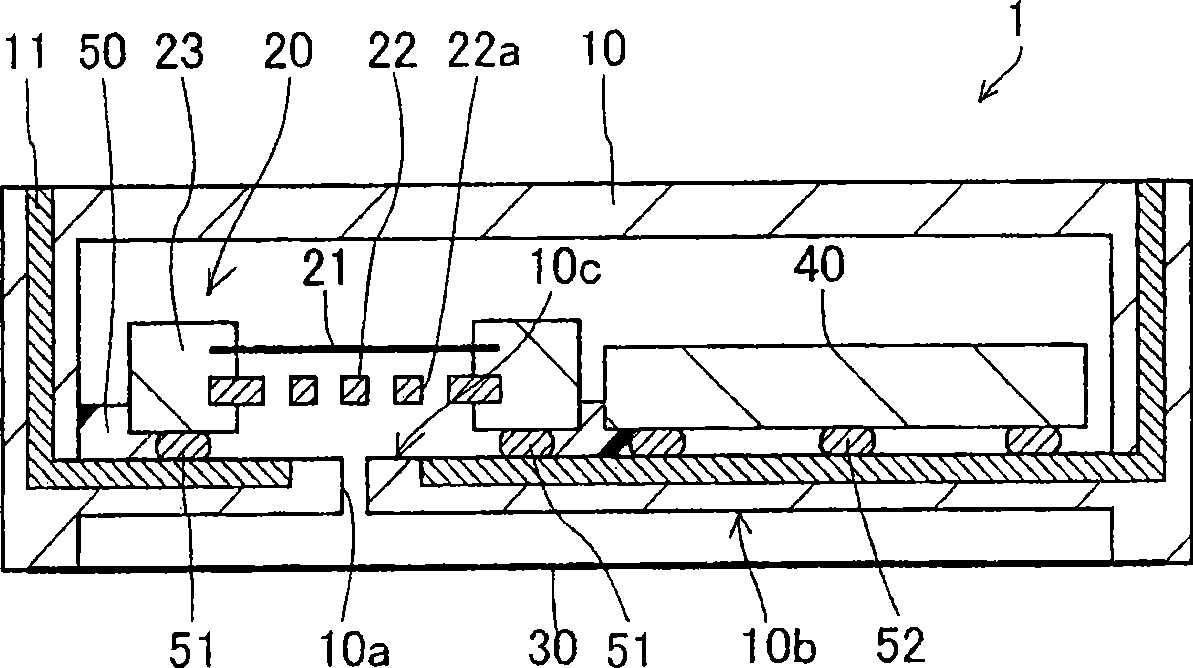

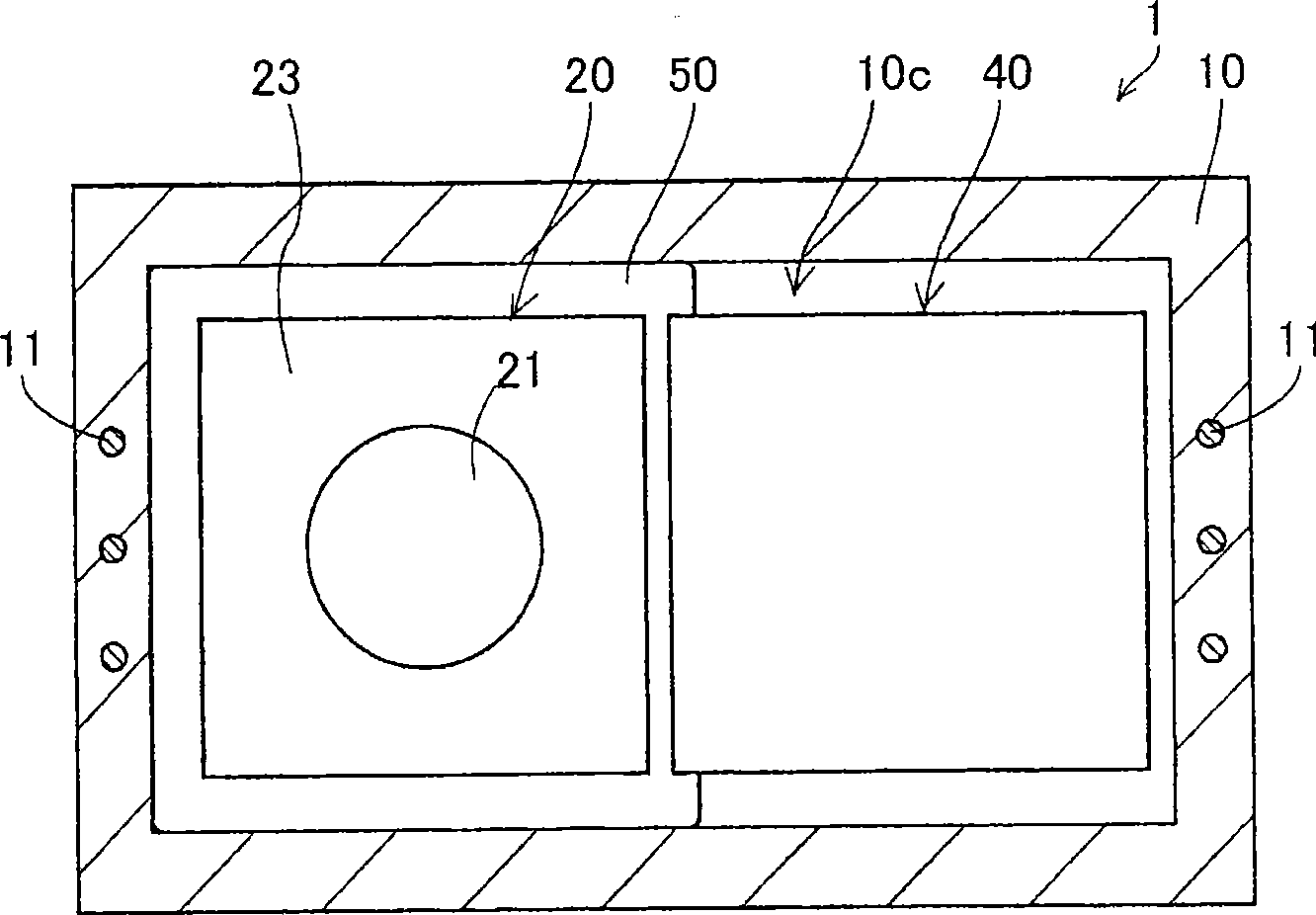

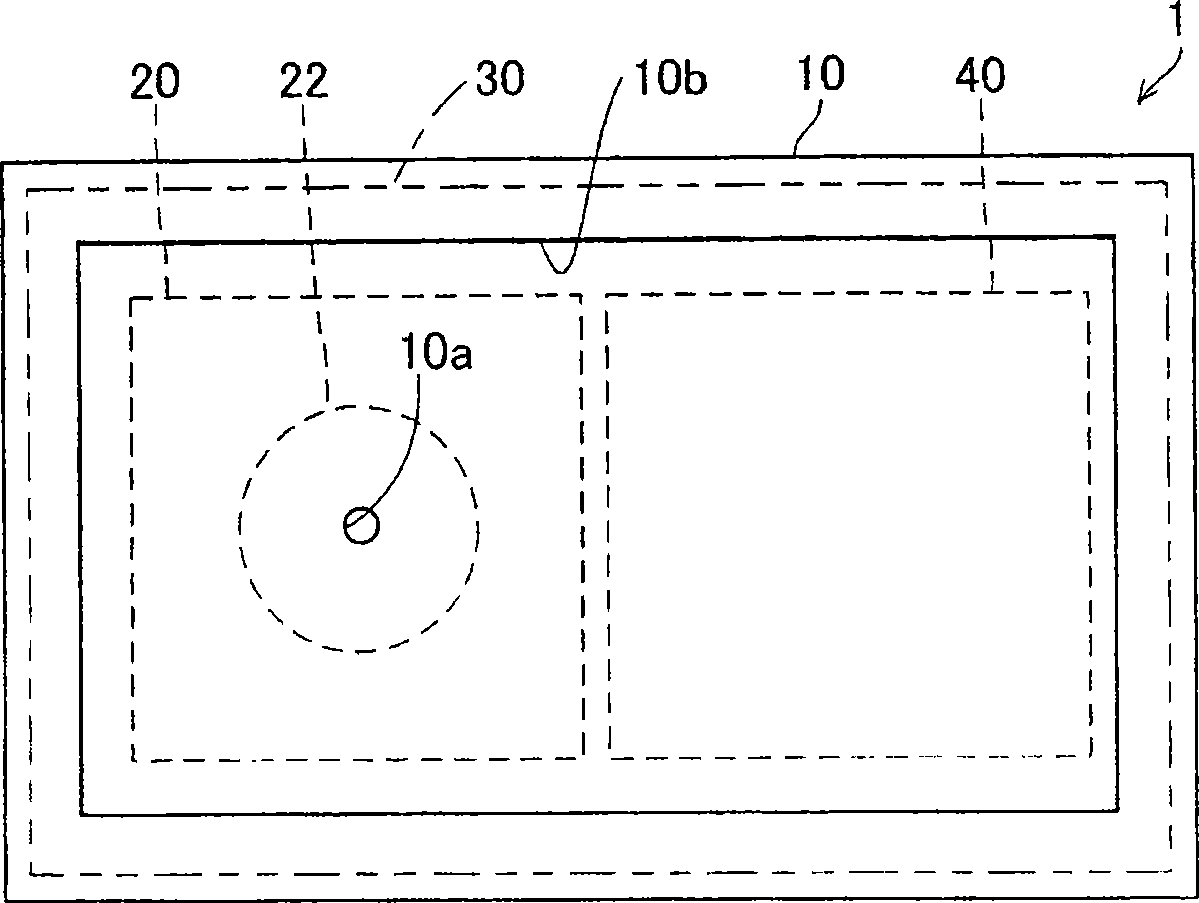

[0040] Figure 1A is a longitudinal sectional view of the vibration sensor, that is, a longitudinal sectional view of the condenser microphone 1 according to the first embodiment of the present invention. Figure 1B is a horizontal cross-sectional view of the condenser microphone 1 . Figure 1C It is a rear view of the condenser microphone 1 with the barrier diaphragm 30 removed.

[0041] The condenser microphone 1 of the first embodiment is a miniature condenser microphone used as a MEMS sensor, which is mounted in a portable electronic device such as a cellular phone. Specifically, the condenser microphone 1 is composed of a microphone die 20 serving as a vibration conversion die, an amplifier die 40 , and a case 10 for accommodating them and a barrier diaphragm 30 for covering the through hole 10 a of the case 10 .

[0042] The housing 10 has a box-like shape formed to accommodate the microphone die 20 and the amplifier die 40 . The case 10 is composed of a sealing material...

no. 3 example

[0088] Figure 4A is a longitudinal sectional view of a condenser microphone 3 which is a vibration sensor according to a third embodiment of the present invention. Figure 4B is a horizontal sectional view of the condenser microphone 3 with the barrier diaphragm 31 removed from its rear side.

[0089] In general, it is preferable to minimize the gap between the barrier diaphragm and the outer surface of the housing in accordance with the vibration of the barrier diaphragm. In the third embodiment, the vibrating membrane 31 is positioned to tightly close the conical recess (or conical recess) of the housing 12 (having the through hole 10a). The barrier diaphragm 31 has an axially symmetric vibration mode in a lower frequency range below its resonance frequency. That is, the amplitude of the barrier diaphragm 31 becomes smaller in the direction from the vibration axis BA (corresponding substantially to the center of the barrier diaphragm 31 ) to the vibration end terminal (co...

no. 4 example

[0091] Figure 5 is a longitudinal sectional view of a condenser microphone 4, which is a vibration sensor according to a fourth embodiment of the present invention. Compared with the condenser microphone 1 , the condenser microphone 4 has a housing 13 having a through hole 10 a covered by a barrier diaphragm 30 . In order to bring the barrier diaphragm 30 into contact with the outer surface 13 b of the housing 13 , a plurality of protrusions 13 d disposed on the opposite side of the barrier diaphragm 30 are formed on the outer surface 13 b of the housing 13 . Instead, only a single protrusion 13d may be formed at a designated area of the outer surface 13b of the housing 13, which may easily come into contact with the barrier diaphragm 30 with a relatively high probability. That is, the number and positions of the protrusions 13d can be optimally determined on the basis of the characteristics and dimensions of the barrier diaphragm 30 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com