Radial pre-tightening method and pre-tightening ring of cylindrical roller bearing

A technology of cylindrical roller bearing and preload ring, which is applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems that the sliding phenomenon of rolling elements cannot be effectively overcome, the cylindrical roller bearing is unfavorable, and the effect is not ideal. The effect of low processing difficulty, low cost and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

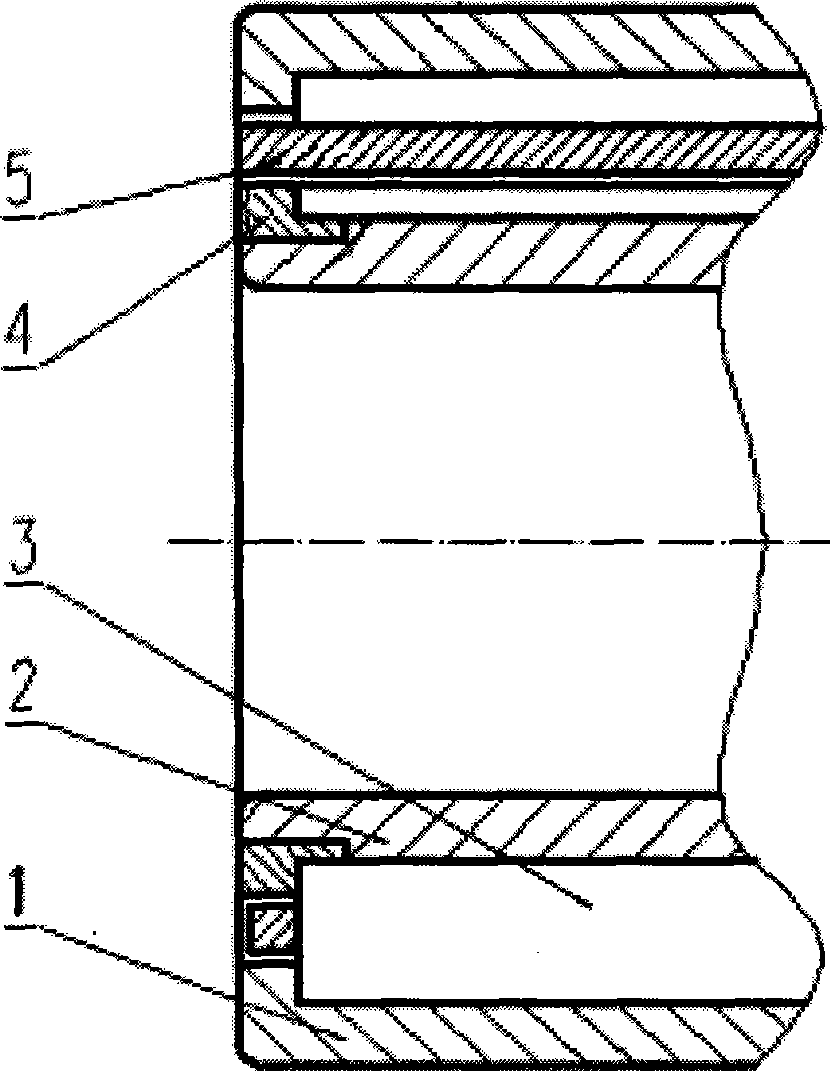

[0020] The radial preloading method of the cylindrical roller bearing of the present invention is to leave a certain space at the position of the inner ring of the bearing, and install a part called a preloading ring in this space, and the preloading ring itself produces Tension forces the rolling elements to be pressed tightly on the outer raceway, and the pretension ring and the inner ring are fixed in the circumferential direction so that there is no relative rotation between them, but a small amount of relative translation can occur in the diameter direction. When there is relative movement between the inner and outer rings and the rolling elements, a frictional force is generated between them. When the frictional force reaches a certain value, the rolling elements can be caused to roll to avoid sliding.

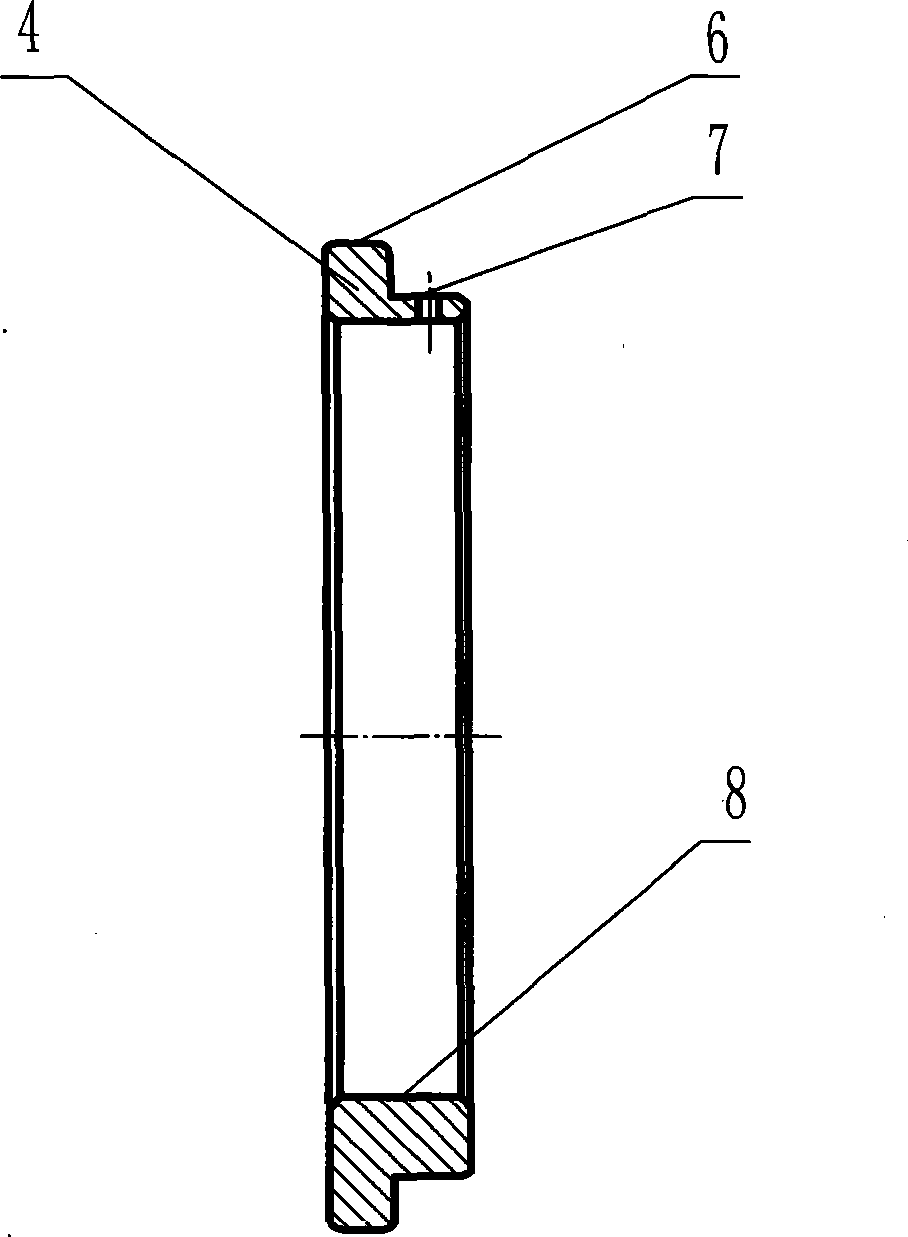

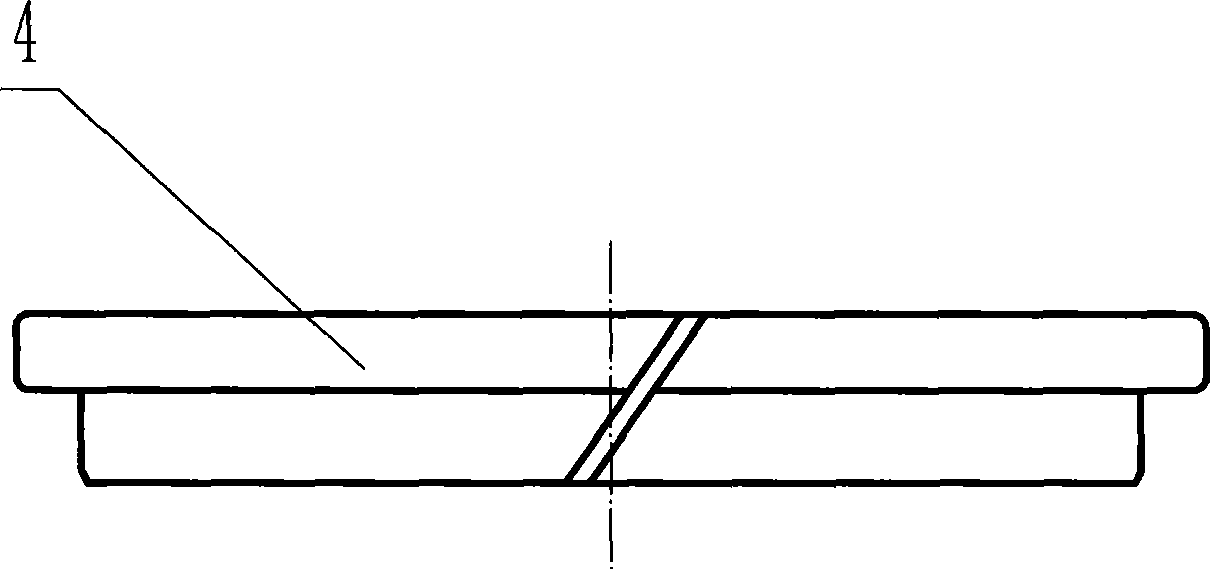

[0021] Such as figure 2 , 3 , Shown in 4 and 5: the radial preload ring (4) of the cylindrical roller bearing of the present invention, its preload ring (4) is made of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com