Slider for concealed type slide fastener with separable bottom end stop

A code stop, invisible technology, applied in the application, sliding fastener components, fasteners, etc., can solve the problem of not being able to install the bottom end stop smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

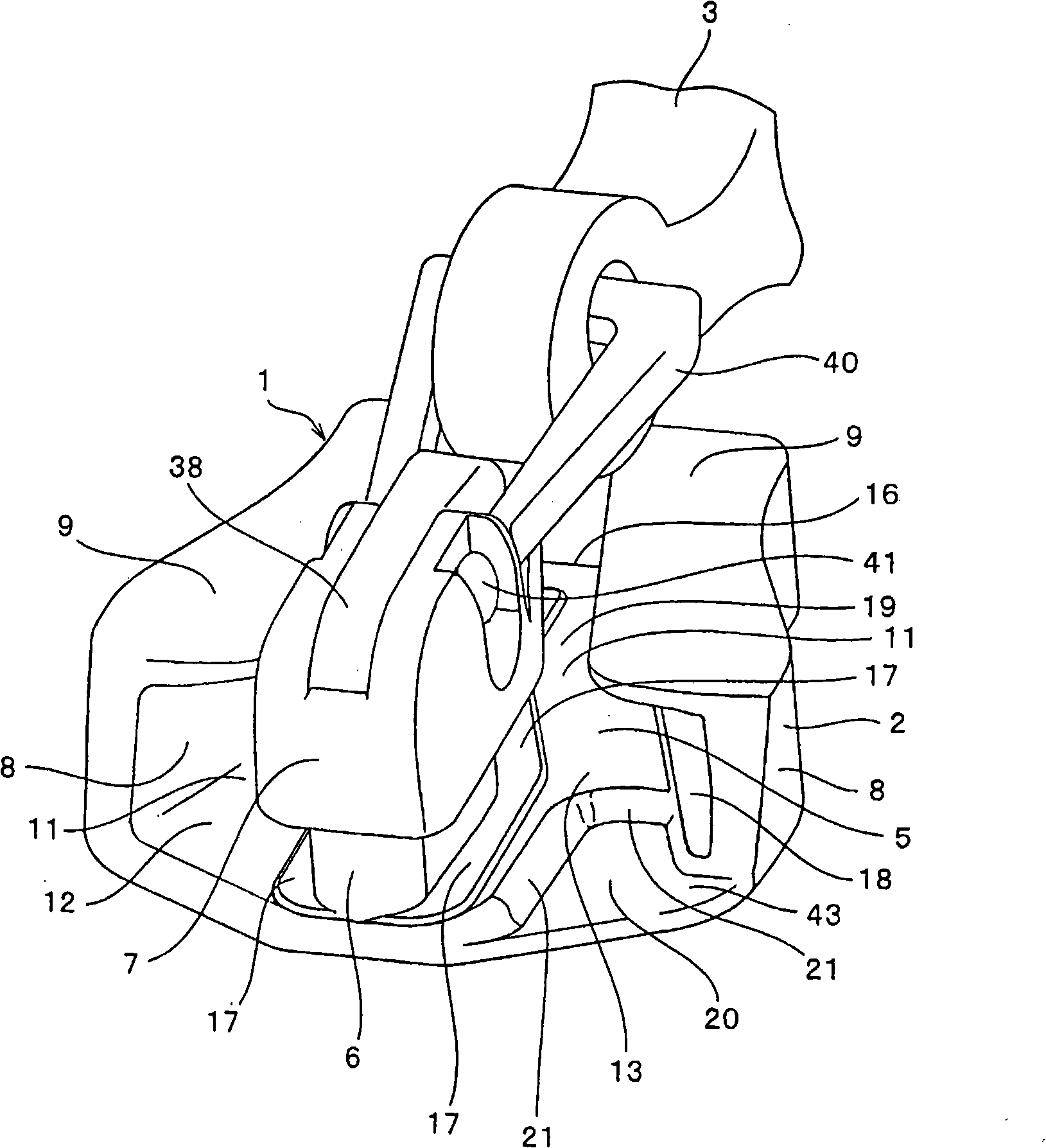

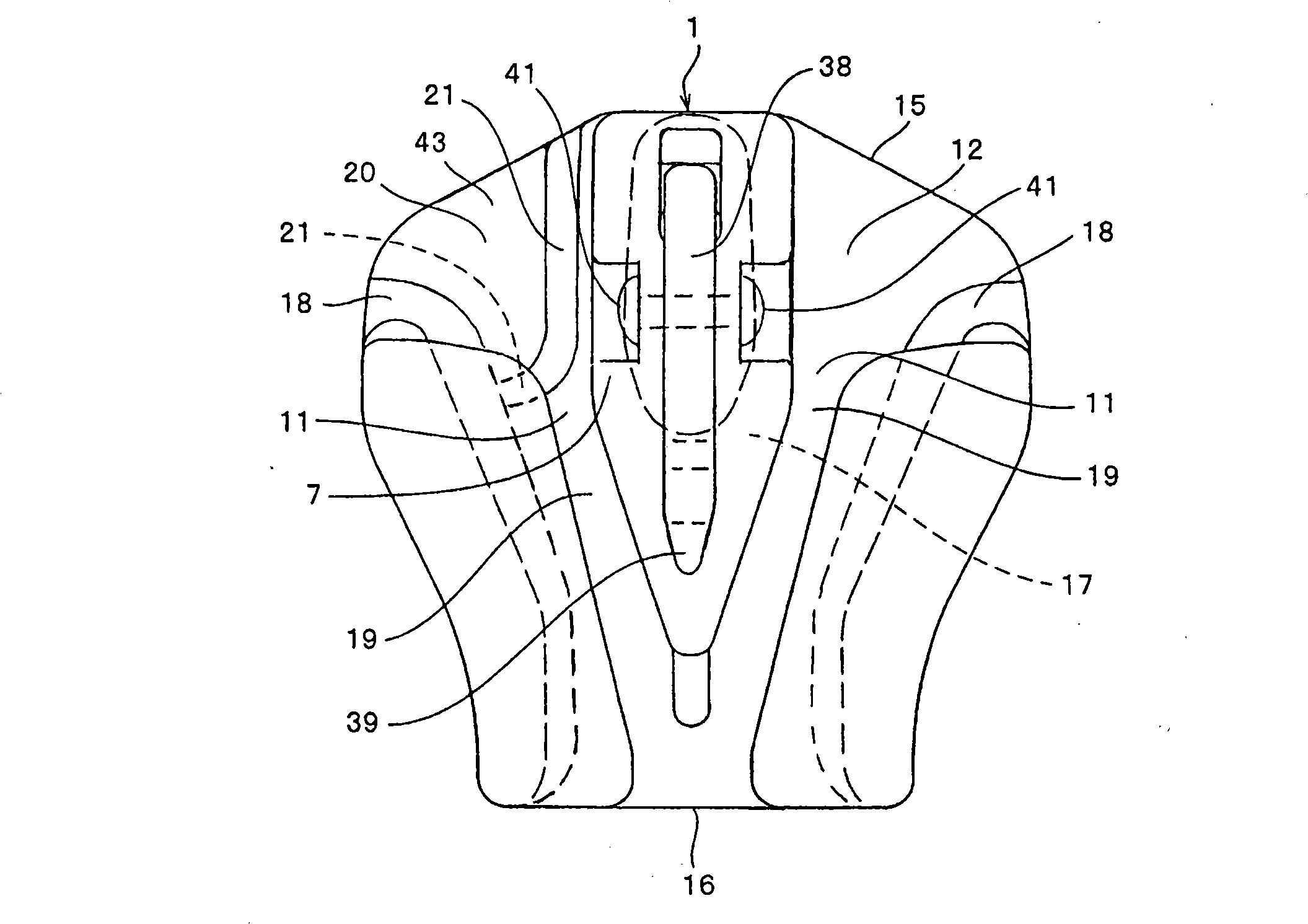

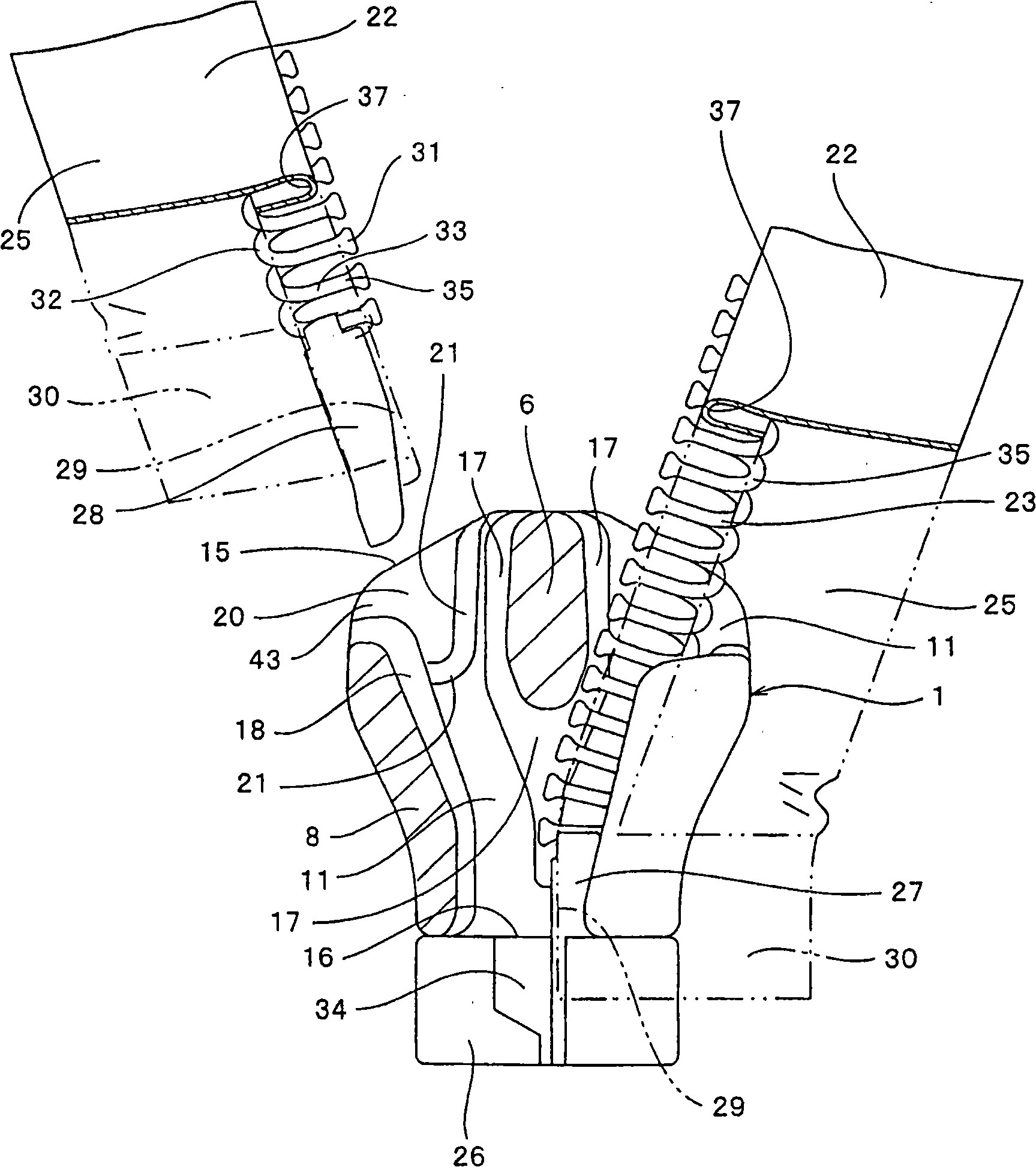

[0046] exist Figure 1 to Figure 7 In the slider for a concealed zipper with a detachable bottom end stop shown in the first embodiment, the main body of the slider 1 and the detachable bottom end consisting of a single socket 26 , seat bar 27 and plunger 28 Stop 4 is made of metal such as aluminum alloy and zinc alloy. In the hidden fastener chain 25 in which the slider 1 passes, the fastener elements 23 are installed along the opposite side edges of the pair of fastener tapes 22 by sewing or the like, and such that the coupling fastener bag 31 is provided inside. A blank portion 29 of the fastener tape 22 in which the fastener elements 23 are not present is provided at one end of the pair of fastener chains 25 , and a reinforcement tape 30 is bonded to the surface thereof. A substantially prismatic seat bar 27 is mounted on the side edge of the blank 29 of one fastener chain 25 adjacent to the fastener elements 23 , while a plunger 28 is mounted on the side edge of the blan...

no. 2 approach

[0058] exist Figure 8 to Figure 10 In the slider for the concealed zipper with a detachable bottom end stop shown in the second embodiment, the wedge part 6 is erected on the lower piece 5 of the main body 2 of the slider 1 so that the wedge part 6 is from the mouth of the teeth The center of 15 extends toward the rear opening 16, and the basic shapes of the handle and bend edges 8 are curvedly provided on both sides of the lower piece 5 are the same as those of the slider 1 of the first embodiment. The second embodiment differs from the first embodiment in that recesses 20 are provided symmetrically on both sides of the wedge 6 in the lower piece 5 of the guide grooves 12 , 13 . The other structures are the same as those of the slider 1 shown in the first embodiment.

[0059] The wedge portion 6 is erected at the center of the tooth foot opening 15 of the lower piece 5, and insertion grooves 12, 13 for inserting the seat rod 27 and the insertion rod 28 are provided on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com