Method for processing short cabo less than 20mm into expanded cut stem

A technology for cut stems and tobacco stems is applied in the field of processing short tobacco stems smaller than 20 mm into expanded cut stems, which can solve the problems of waste of short tobacco stems, and achieve the effects of improving the quality of smoking, good elasticity and increasing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

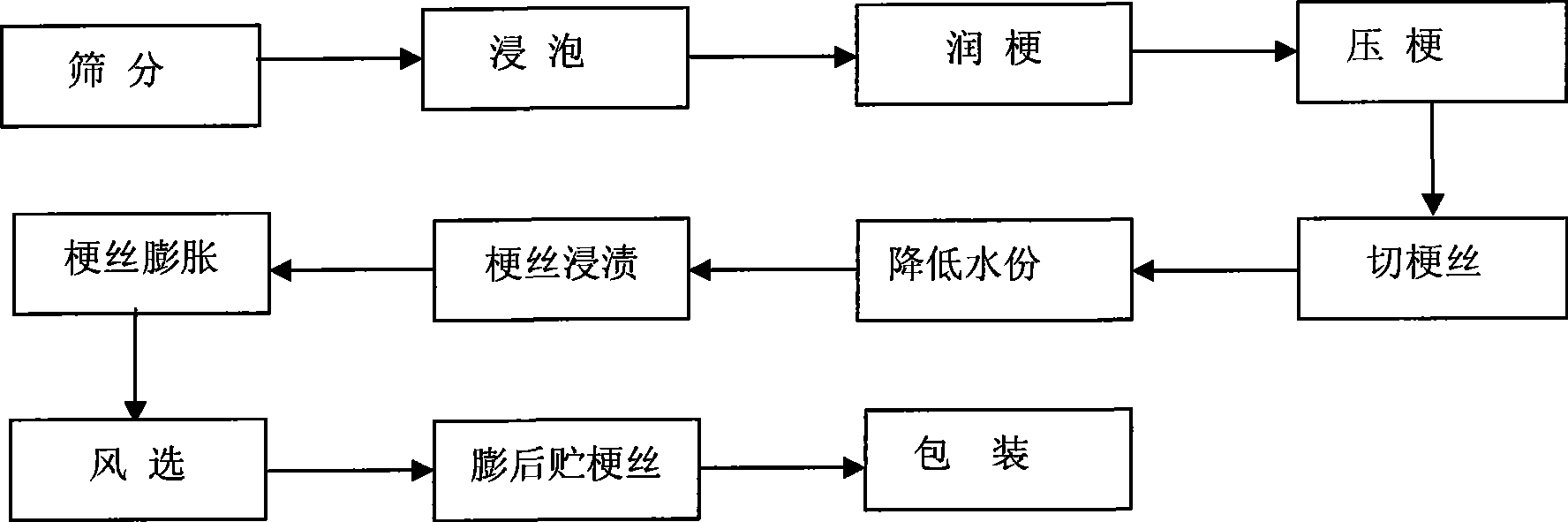

[0015] Other technical problems of the present invention are described in detail below. Different from the processing technology of the long tobacco stems in the prior art, aiming at the physical and chemical properties of the short tobacco stems, we adopt the processing technology of pressing the stems after fully soaking, shredding the stems after pressing, and expanding with dry ice after shredding. The length of the short tobacco stem is less than 20mm, the physical size is short, and the processing resistance is weak. If the stem is directly pressed, it will be severely broken and the stems will be difficult to shape. The void volume increases, the specific surface area increases, the processing resistance of the tobacco stem is significantly improved, and the crushing and shredding rate of the tobacco stem is significantly reduced; in the prior art, the tobacco stem is not pressed before shredding, and some of the tobacco stems are pressed. It is thicker, generally great...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com