Flame-proof fireproof facing material

A technology of fire-resistant fabrics and raw materials, applied in the direction of fabrics, textiles, textiles, and papermaking, can solve the problems of reduced flame-retardant, fire-resistant, and tear-resistant strength, and achieve short burning time, high wear resistance, and good flame-retardant effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The blended yarn of meta-aramid fiber, para-aramid fiber and organic antistatic fiber is used as the warp and weft yarn raw materials of the fabric. In the entire fabric, for example, in every 100 grams of fabric, meta-aramid The weight percentage of fiber is 93%, the weight percentage of para-aramid fiber is 5%, and the weight percentage of organic antistatic fiber is 2%. According to the traditional spinning, dyeing, weaving and finishing processes, the flame retardant and fireproof fabric is obtained. In this embodiment, the organic antistatic fiber is a short fiber with a specification of 3D or less obtained by composite spinning of carbon black and polyamide fiber material. This organic antistatic fiber is preferably made by Kanebo Co., Ltd. The name of the product produced and sold by the company is Beirut Lun Organic Antistatic Fiber. In this embodiment, the specifications of the para-aramid fiber and the meta-aramid fiber are short fibers below 3D. The yarns obtaine...

Embodiment 2

[0017] Only change the weight percentage of meta-aramid fiber to 70%, change the weight percentage of para-aramid fiber to 26%, and change the weight percentage of organic antistatic fiber to 4%. The number is 36S / 2. The rest is the same as the description of Embodiment 1.

Embodiment 3

[0019] Only the weight percentage of meta-aramid fiber is changed to 85%, the weight percentage of para-aramid fiber is changed to 13.5%, the weight percentage of organic antistatic fiber is changed to 1.5%, and the count of blended yarn is 48S / 2. The rest is the same as the description of Embodiment 1.

[0020] It can be seen from the above embodiments that the raw materials used in the warp structure of the flame-retardant and fire-resistant fabric are meta-aramid fibers, para-aramid fibers and organic antistatic fibers; the raw materials used in the weft structure of the flame-retardant and fire-resistant fabrics are also used Meta-aramid fiber, para-aramid fiber and organic antistatic fiber. The relationship between the warp and weft yarns of the obtained flame-retardant and fire-resistant fabric can be either a plain weave structure or a twill weave structure.

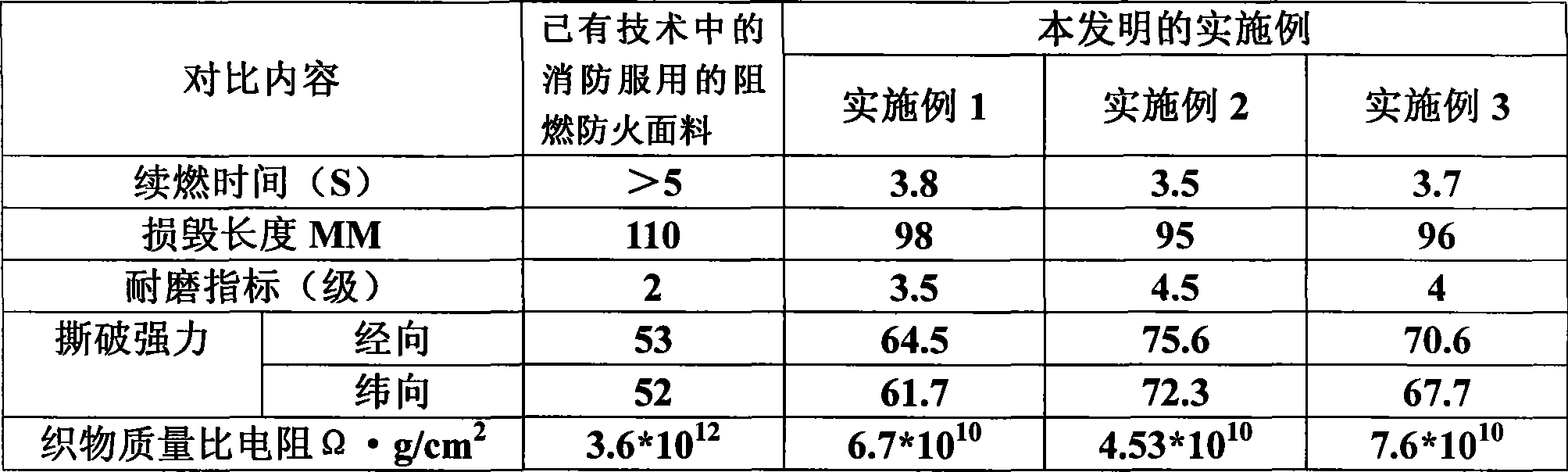

[0021] The flame-retardant and fire-retardant fabrics obtained from the above-mentioned embodiments have excellent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com