Method for purifying chicoric acid and monocaffeyltartaric acid from echinacea purpurea extract

A technology of caffeoyl tartaric acid and Echinacea purpurea extract, applied in the separation/purification of carboxylic acid esters, organic chemistry, pharmaceutical formulations, etc., to achieve the effects of saving production costs, low elution costs, and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Separation and purification:

[0026] (1) Processing of sample solution: take 3.755g of 4% Echinacea purpurea extract, add water 18mL, ultrasonically extract for 30min to dissolve it, filter under reduced pressure, wash the filter residue with 4mL of water, combine the filtrate, add 1mL of 18% hydrochloric acid, make The pH is between 1-4; that is, the sample solution is obtained.

[0027] (2) Configuration of different gradient eluents: configure three different gradient eluents with hydrochloric acid, the volume fraction of hydrochloric acid is respectively: A eluent=0.07%; B eluent=0.03%; C eluent= 0.015%.

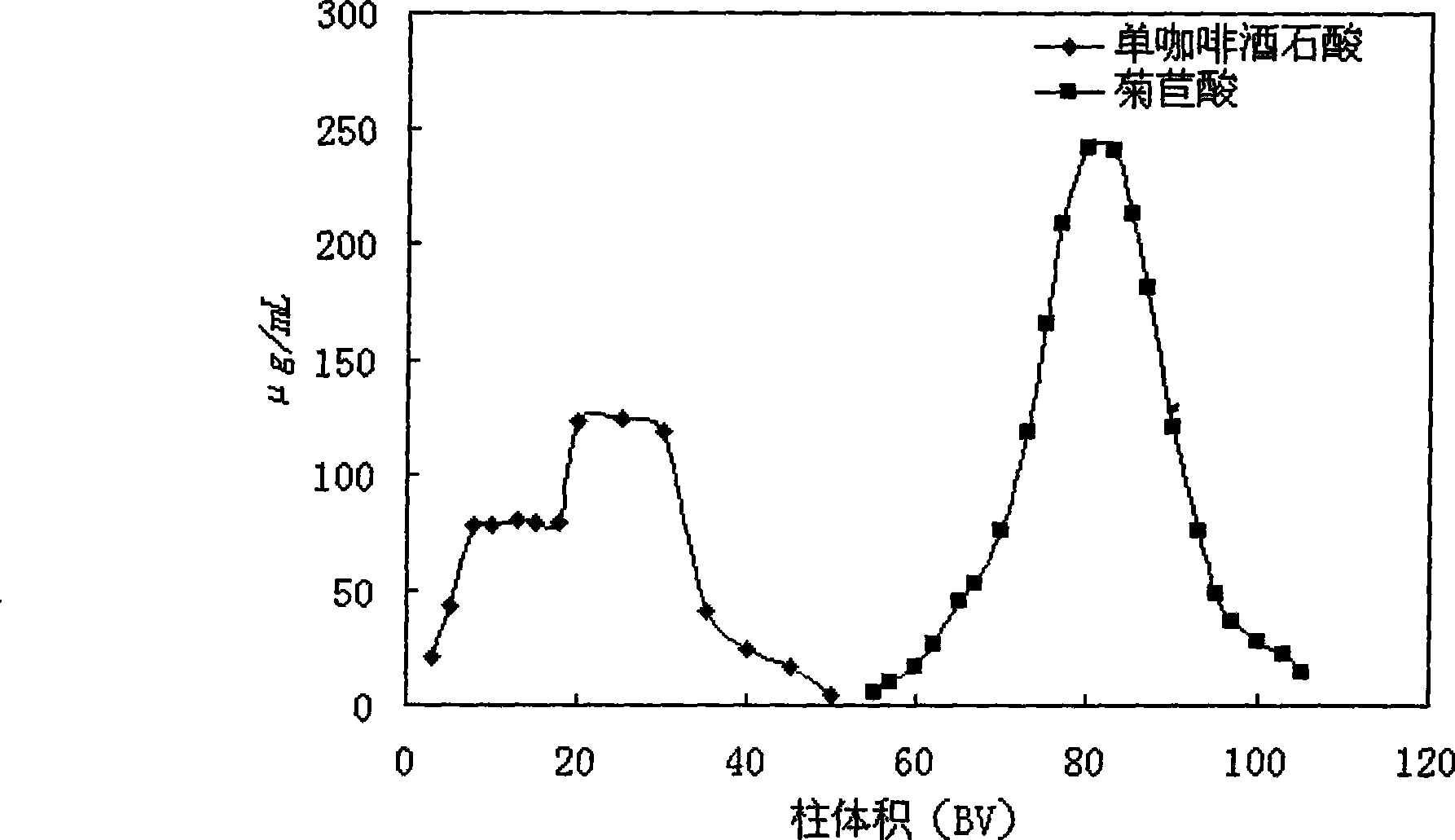

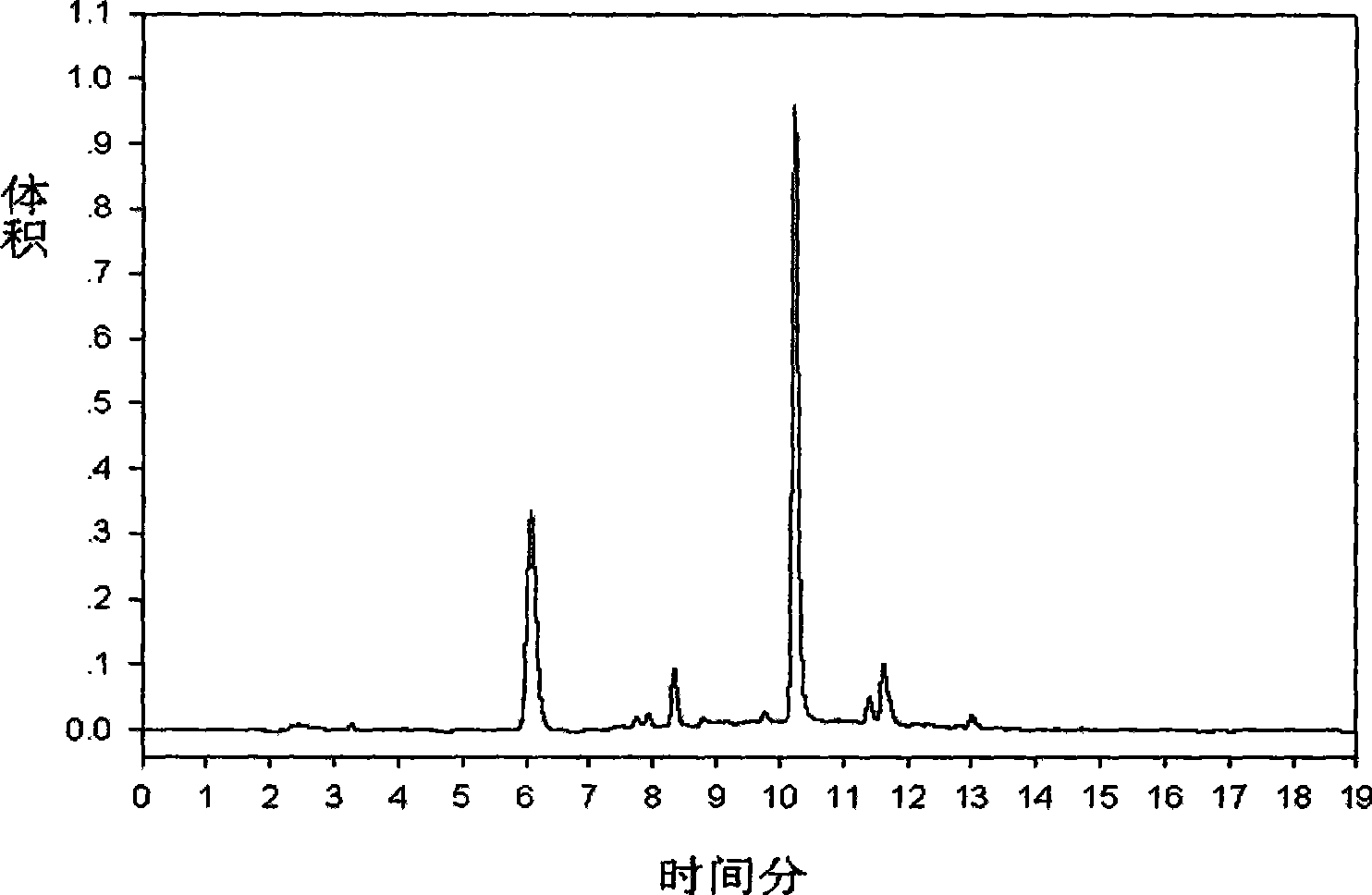

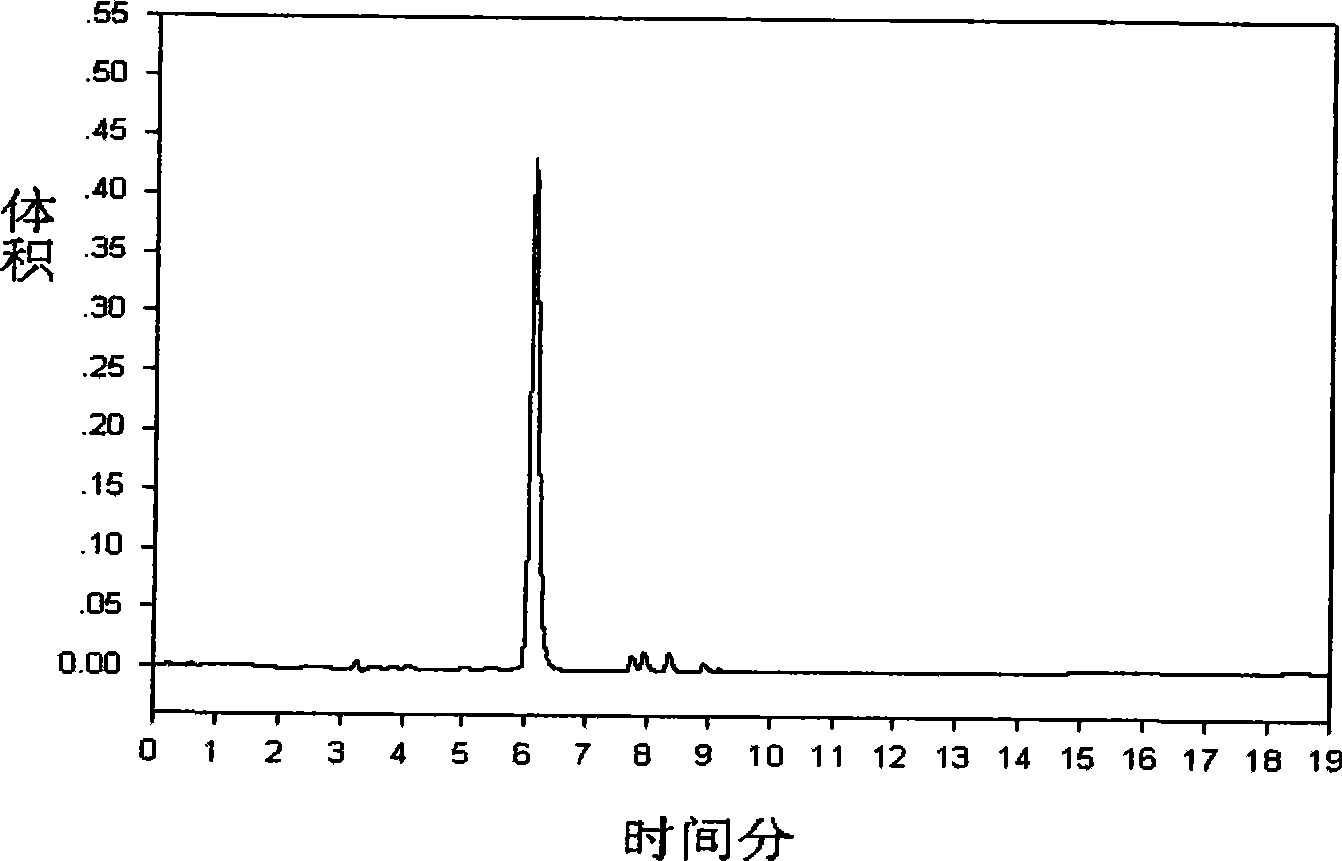

[0028] (3) Column loading: wet-load the processed hpd100 non-polar macroporous adsorption resin into a 50cm×1.0cm glass chromatography column, and the volume of the macroporous adsorption resin is 35cm 3 , equilibrate the macroporous adsorption resin with 5 times column volume (BV) of A eluent, and then add the sample solution to the chromatography column e...

Embodiment 2

[0038] (1) Separation and purification:

[0039] (1) Treatment of sample solution: Take 2000g of 4% Echinacea purpurea extract, add 5200mL of water, stir to dissolve it, filter under reduced pressure, wash the filter residue with 400mL of water, combine the filtrates, add 50% of hydrochloric acid 500mL, and obtain the above sample liquid.

[0040] (2) Configuration of different gradient eluents: configure three kinds of eluents with different gradients with sulfuric acid, the volume fraction of sulfuric acid is respectively: A eluent=0.05%; B eluent=0.03%; C eluent= 0.01%.

[0041] (3) Go to the column; the macroporous adsorbent resin that has been processed will be wet-packed in the glass chromatography column (100cm * 8.0cm), and the volume of the macroporous adsorbent resin is 13500cm 3 , equilibrate the macroporous adsorption resin with 5 times the column volume (BV) A eluent, and then add the sample solution to the chromatography column at a speed of 3-10 minutes per 1 ...

Embodiment 3

[0049] (1) Separation and purification:

[0050] (1) Treatment of sample solution: Take 3000g of 4% Echinacea purpurea extract, add 8000mL of water, stir to dissolve it, filter under reduced pressure, wash the filter residue with 450mL of water, combine the filtrates, add 500% of hydrochloric acid 500mL, and obtain the above sample liquid.

[0051] (2) Configuration of different gradient eluents: configure three different gradient eluents with acetic acid, the volume fraction of acetic acid is respectively: A eluent=0.1%; B eluent=0.04%; C eluent=0.04%; 0.02%.

[0052] (3) Column loading: wet-load the treated macroporous adsorption resin into a glass chromatography column (100cm×8.0cm), the volume of the macroporous adsorption resin is 1350cm 3 , equilibrate the macroporous adsorption resin with 5 times the column volume (BV) A eluent, and then add the sample solution to the chromatography column at a speed of 3-10 minutes per 1 BV.

[0053] (4) Use A, B, and C three eluent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com