Method and blank for manufacturing a compressor block of a small-type refrigeration appliance

A technology of refrigeration equipment and compressors, used in mechanical equipment, machines/engines, liquid variable capacity machinery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

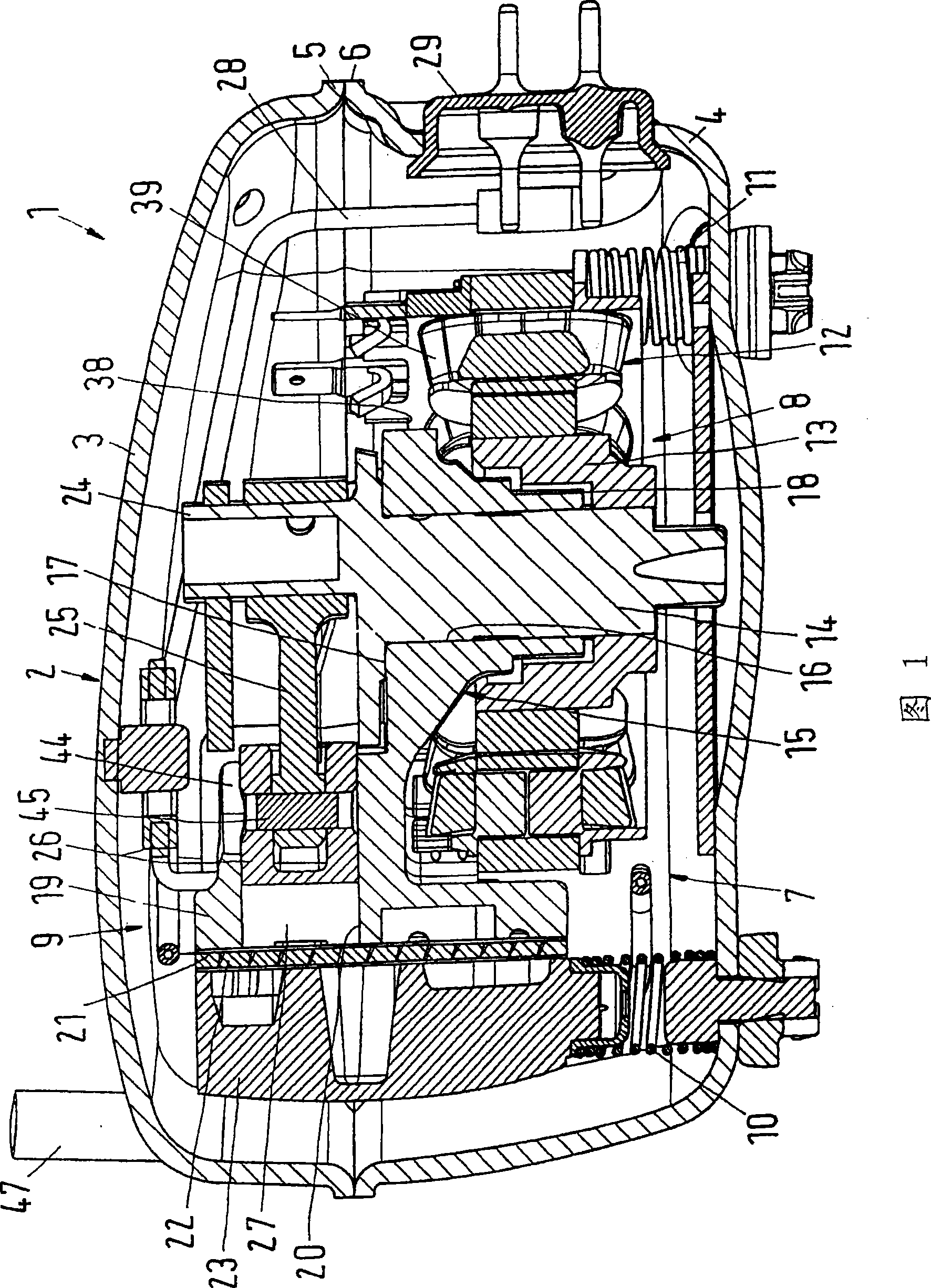

[0029] The refrigerant compressor arrangement 1 has a housing 2 with an upper part 3 and a lower part 4 . The upper part 3 has a flange 5 and the lower part 4 has a flange 6 . The upper part 3 and the lower part 4 are welded together or otherwise sealedly connected to each other along these flanges.

[0030] The housing houses a unit 7 comprising a motor 8 and a compressor part 9 . The unit 7 is supported in the lower part 4 via a plurality of springs 10 , 11 (two can be seen).

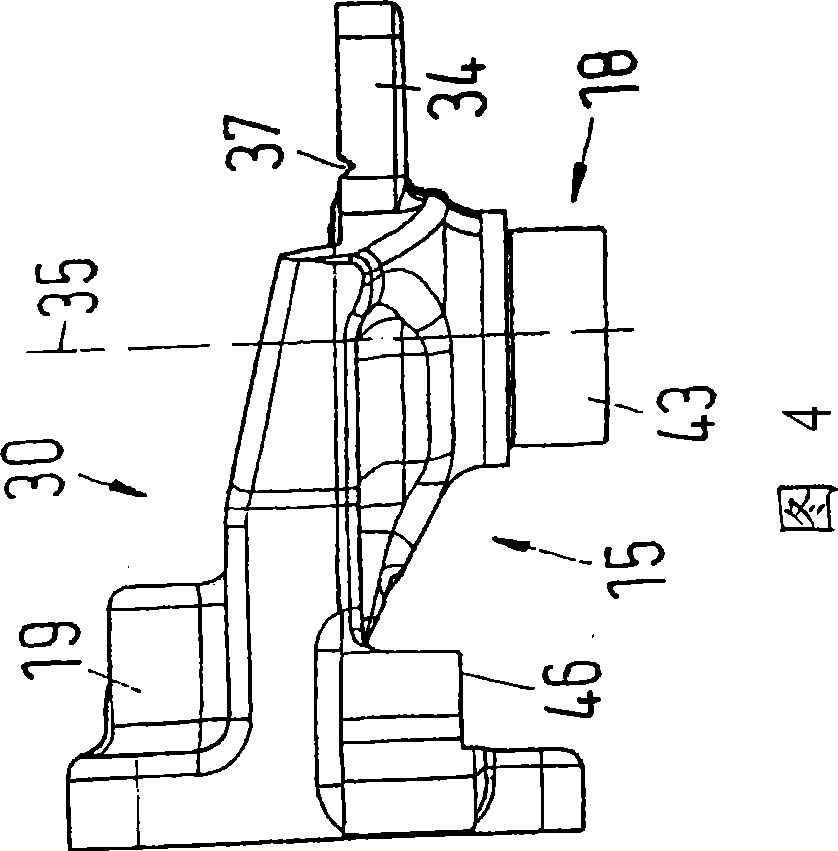

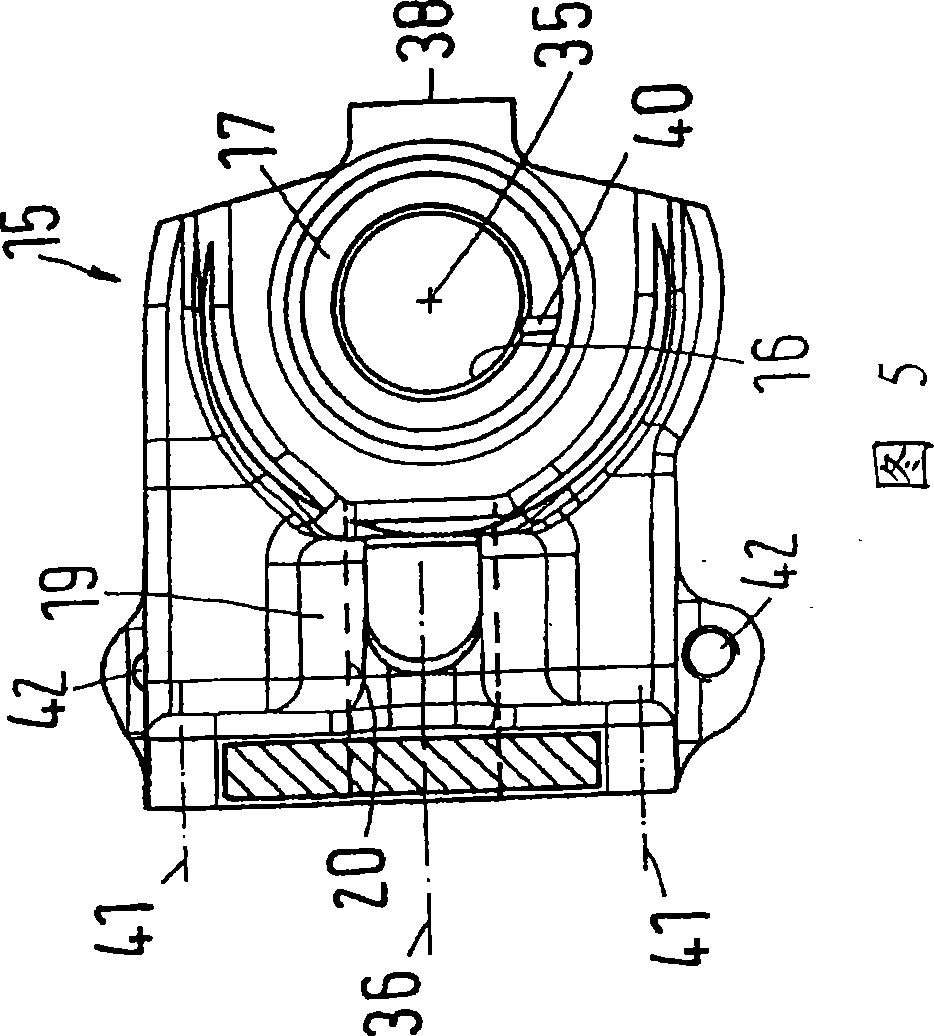

[0031] The motor 8 includes a stator 12 and a rotor 13 . The rotor 13 is non-rotatably connected to the crankshaft 14 . The crankshaft 14 is rotatably supported in a compressor block 15 . For this purpose, the compressor block 15 includes a radial bearing 16 and an axial bearing 17 . An axial bearing 16 is located in a bearing portion 18 of the compressor block 15 .

[0032] The stator 12 of the motor 8 is fixed on the compressor body 15 . Here, this fixation lies outside the plane of the drawi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com