Mechanized method for processing flat green tea

A processing method and flat technology, applied in the field of mechanized processing of flat green tea, can solve problems such as poor tea smoothness, low production efficiency, and high labor intensity, and achieve stable quality, low production cost, and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: the optimization of method parameter

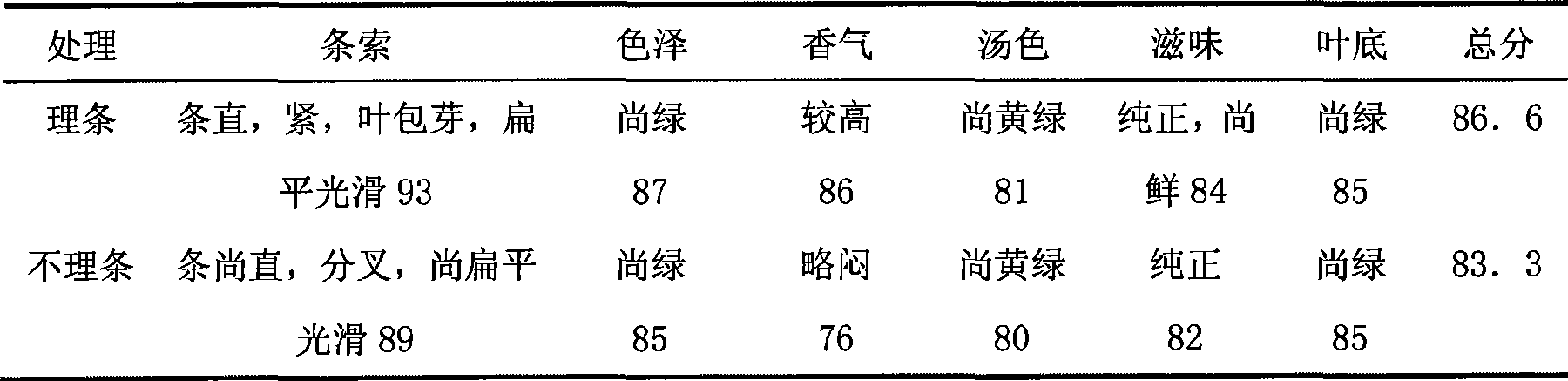

[0022] Use one bud and one leaf of the Fuding large white tea tree variety as the material, mix the fresh leaves evenly, spread them according to the method of spreading—finishing (6CST-40 type roller continuous greening machine, Zhejiang Lvfeng Machinery Co., Ltd.)—spreading to cool and regain moisture—trimming ( 11-slot carding machine, Zhejiang Lvfeng Machinery Co., Ltd.)—flattening and shaping (6CLZ-60 reciprocating multipurpose machine, Zhejiang Lvfeng Machinery Co., Ltd.)—cooling and regaining moisture—solid shape (6CBG-60 flat tea solidification machine , Zhejiang Lvfeng Machinery Co., Ltd.) to Zugan process operation, to study the difference in the quality of flat tea treated with strips and without strips. The sensory evaluation results show that the tea samples treated with strips after finishing have a higher score, and the strips The cable is tight and straight, the leaves cover the buds, flat and smooth, ...

Embodiment 2

[0026] Embodiment 2: Do the optimization of shape parameters

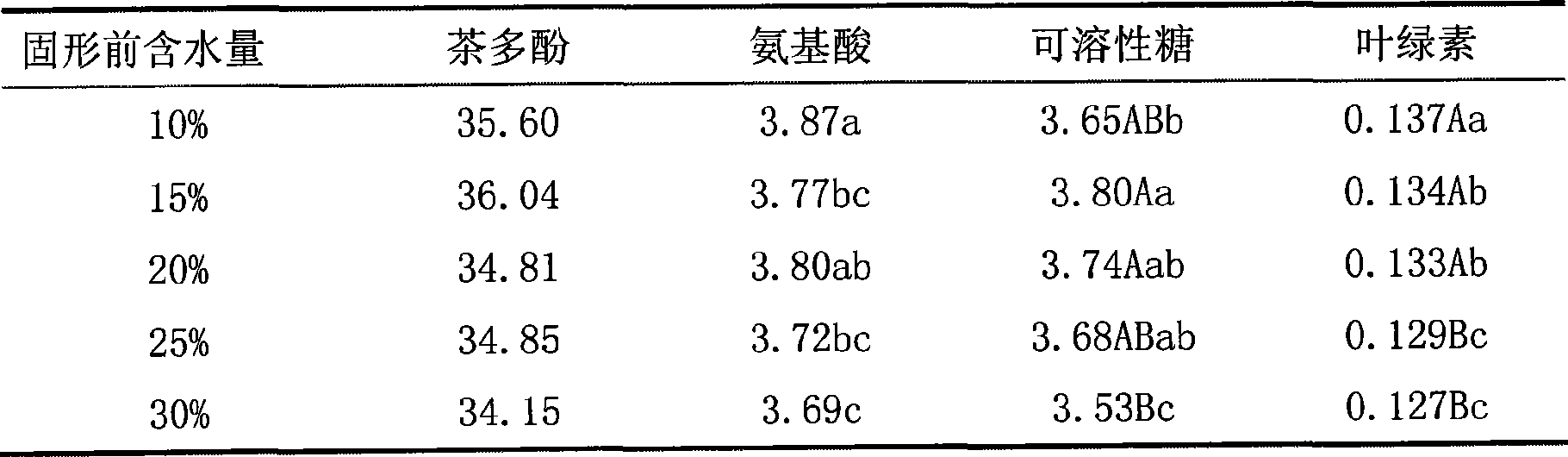

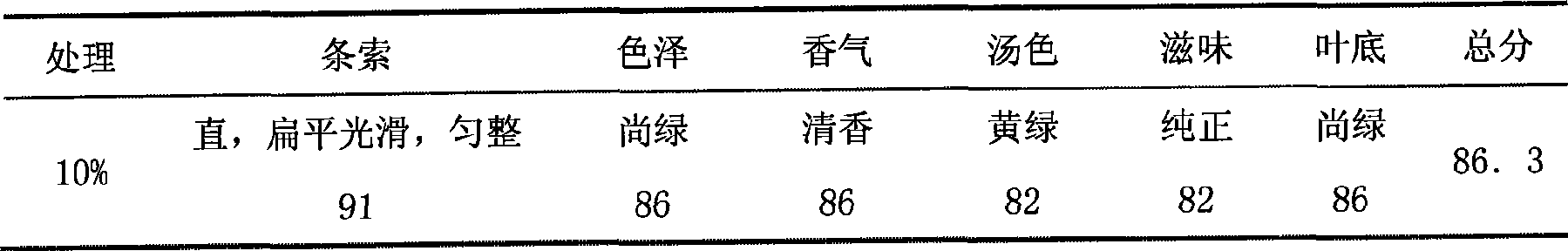

[0027] Use one bud and one leaf of the Fuding large white tea tree variety as the material, mix the fresh leaves evenly, and spread them according to the method of spreading—finishing (6CST-40 type drum continuous greening machine)—spreading to cool and regain moisture—trimming (11-slot stripping machine)— Squeeze and shape (6CLZ-60 reciprocating multi-purpose machine)—spread to cool and regain moisture—solidify (6CBG-60 flat tea solidifying machine, until dry enough) process operation, compare the influence of water content of shaped leaves on quality, According to the analysis of the main quality components (Table 3) and the sensory evaluation results (Table 4), combined with the actual production, the process parameters of the multi-purpose machine are obtained: the water content of solid leaves is 15-20%.

[0028] Table 3 Analysis results of the main quality components of famous flat-shaped teas treated with wa...

Embodiment 3

[0035] Embodiment 3: Solid parameter optimization

[0036] Use one bud and one leaf of the Fuding large white tea tree variety as the material, mix the fresh leaves evenly, and spread them according to the method of spreading—finishing (6CST-40 type drum continuous greening machine)—spreading to cool and regain moisture—trimming (11-slot stripping machine)— The process of flattening and forming (6CLZ-60 reciprocating multi-purpose machine, instrument temperature 120-130°C, 3 catties of leaves per pot)-spreading to cool and regain moisture-solid (6CBG-60 flat tea solidifying machine, until dry enough) Process operation. On the basis of the single factor experiment of water content before solidification, solidification temperature and solidification leaf amount, L 9 (3 4 ) Orthogonal experimental design method to optimize the solid parameters, and the factors and levels of the orthogonal design are shown in Table 5. The sensory evaluation results of single factor test of solid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com