External insulator for mutual-inductor

A technology for external insulation and transformers, which is applied in the direction of insulators, inductors, transformers, etc., can solve the problems of external insulation performance degradation, surface pulverization, ultraviolet resistance, arc resistance and other poor performance, and achieve pollution-resistant service life and improve Effect of Low Temperature Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

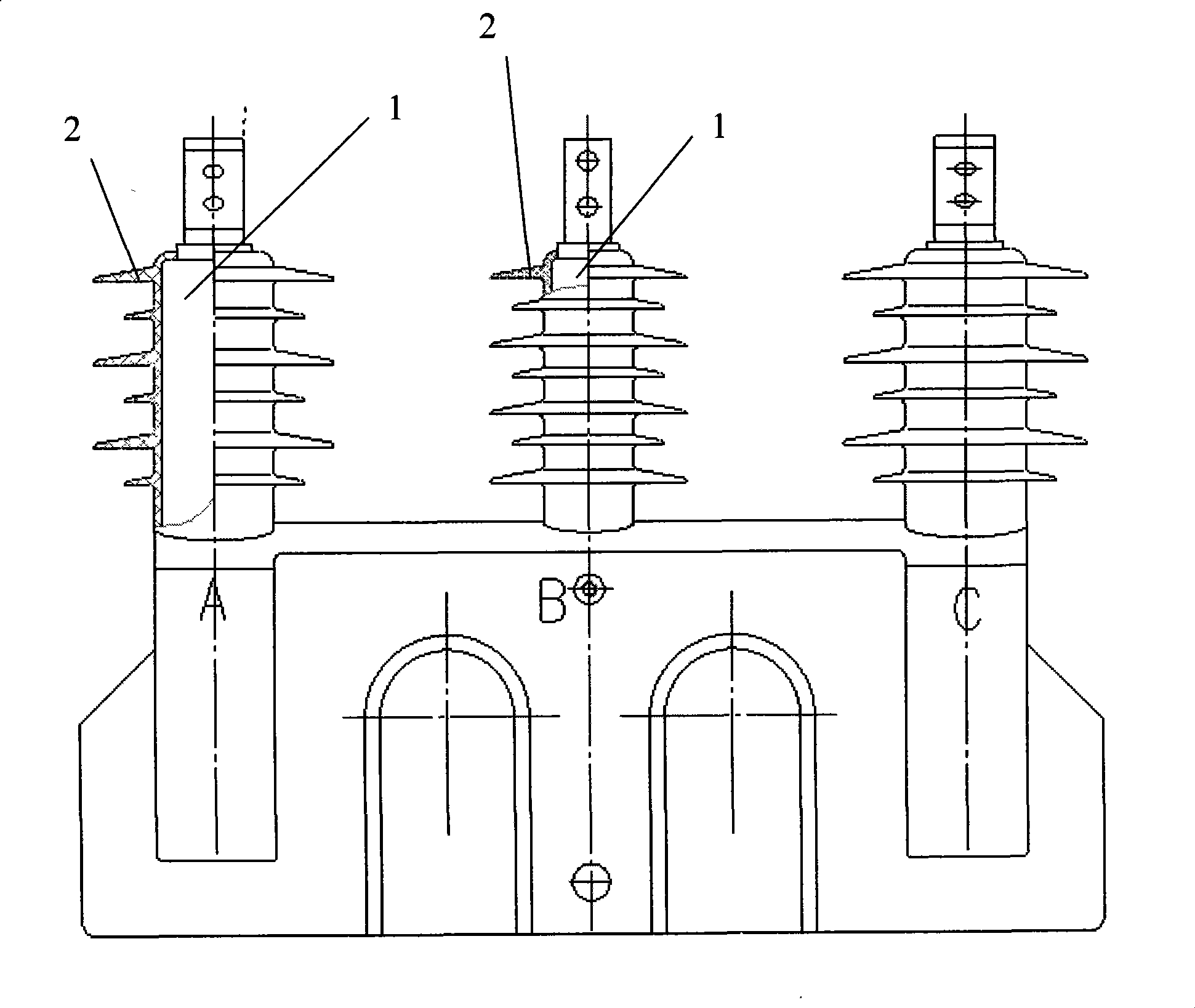

[0007] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0008] Such as figure 1 As shown, the outer insulation of a transformer is provided with an epoxy resin layer 1 , and the outside of the epoxy resin layer 1 is entirely covered with a silicon rubber layer 2 . This product vulcanizes the silicone rubber layer 2 directly on the surface of the epoxy resin layer 1, without bonding and without gaps. The specific production process is as follows: First, the body is cast into one body with a special formula of low-temperature resistant epoxy resin, and then the liquid silicone rubber vulcanization production line imported from Germany is used to encapsulate all parts of the product except the outlet end in silicone rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com