Laser-induced microparticle jetting ignition method

A laser-induced, particle-based technology, applied in the direction of engine ignition, engine components, machines/engines, etc., can solve the problems of unfavorable engine continuous ignition work, large heating area, long ignition delay time, etc., to achieve convenient and high-frequency continuous ignition The possibility of overcoming the effect of large heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] figure 1 The experimental device shown includes a laser 1 and a combustion chamber body. The combustion chamber body is provided with a combustion chamber 6 and an explosion-proof section 8. An aluminum explosion-proof film 7 is arranged between the combustion chamber 6 and the explosion-proof section 8. On the front wall of the combustion chamber 6 A focusing lens 2 matching the laser 1 is provided, a detection window 3 and three pressure sensors 4 are provided on the side wall of the combustion chamber 6, and an absorption target 5 is provided at the focal point of the focusing lens in the combustion chamber 6.

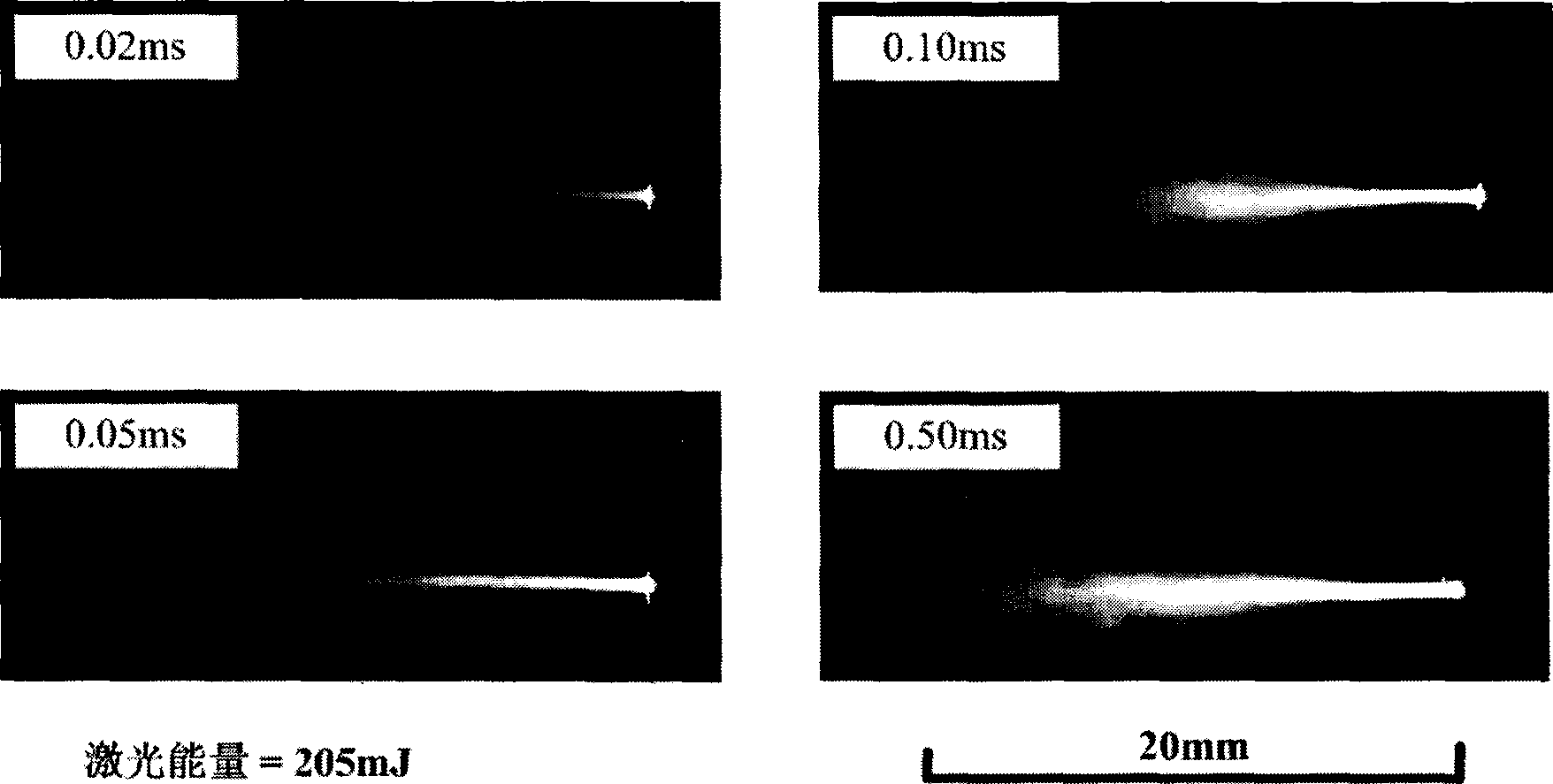

[0021] When using the above-mentioned experimental device to conduct experiments, the mixture of gaseous or liquid atomized hydrocarbon fuel and oxygen or air is placed in the combustion chamber 6 in advance, and the laser pulse emitted by the laser 1 is irradiated into the combustion chamber 6 through the focusing lens 2 and focused To the surface of the abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com