Brew method of plasmogen cherry wine

A technology of cherry wine and fruit wine yeast, which is applied in the field of wine making, can solve the problems of lack of market competitiveness, low product quality, and low utilization rate of raw materials, and achieve the effects of preventing cardiovascular diseases, reducing fat accumulation, and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

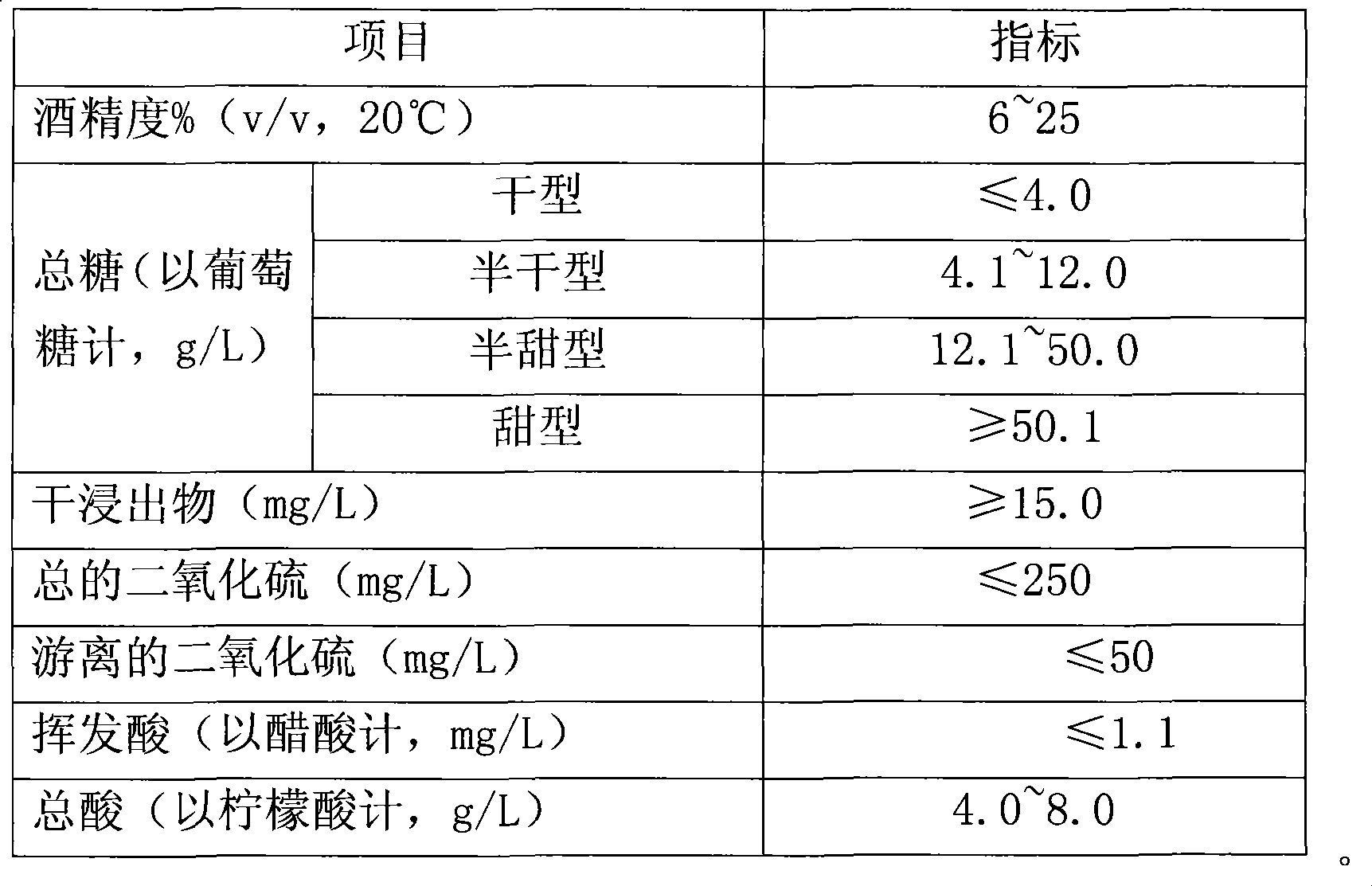

[0009] Choose 500kg of fresh cherry fruit with high sugar content and fully ripened fruit, and get rid of inferior fruit; wash off the dirt on the skin, soak in 3% hydrogen peroxide, and drain the water after washing. After squeezing the juice, add 150g of Vc according to the ratio of 0.3‰ of the raw pulp, add fruit wine yeast and aroma yeast according to 1.5% of the feed liquid, and carry out temperature-controlled co-fermentation. The fermentation temperature is 24°C, and the fermentation time is 10 days. Main fermentation When it's over, immediately separate the pomace. After controlling the fermentation temperature was 16°C, after 30 days, the residual sugar in the fermented mash was ≤4g / L, and the post-fermentation stopped. After aging, the kirsch was filtered with diatomaceous earth, and the cherry wine was further clarified and filtered by cross-flow microporous membrane filtration technology, and finally the 10-degree puree wine was obtained.

Embodiment 2

[0011] Select 1000kg of fresh cherry fruit with high sugar content and fully ripened, and get rid of inferior fruit; wash the skin dirt, soak with 3% hydrogen peroxide, and drain the water after washing. After squeezing the juice, add 300g of Vc according to the ratio of 0.3‰ of the raw pulp, add fruit wine yeast and aroma yeast according to 1.5% of the liquid amount, and carry out temperature-controlled co-fermentation. The fermentation temperature is 20°C, and the fermentation time is 10 days. Main fermentation When it's over, immediately separate the pomace. After controlling the fermentation temperature is 20°C, after 20 days, the residual sugar in the fermented mash is ≤4g / L, and the post-fermentation stops. After aging, the kirsch was filtered with diatomaceous earth, and the cherry wine was further clarified and filtered by cross-flow microporous membrane filtration technology, and finally the 16-degree puree wine was obtained.

Embodiment 3

[0013] Choose 500kg of fresh cherry fruit with high sugar content and fully ripened fruit, and get rid of inferior fruit; wash off the dirt on the skin, soak in 3% hydrogen peroxide, and drain the water after washing. After squeezing the juice, add 50g of Vc according to the ratio of 0.1‰ of the raw pulp, add fruit wine yeast and aroma yeast according to 2.0% of the liquid amount, and carry out temperature-controlled co-fermentation. The fermentation temperature is 18°C, and the fermentation time is 15 days. Main fermentation When it's over, immediately separate the pomace. After controlling the fermentation temperature is 20°C, after 20 days, the residual sugar in the fermented mash is ≤4g / L, and the post-fermentation stops. After aging, the kirsch was filtered with diatomaceous earth, and the cherry wine was further clarified and filtered by cross-flow microporous membrane filtration technology, and finally the 10-degree puree wine was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com