Method for decolorization preparation of pale rosin by rosin containing non-decoloring agent

A light-coloring agent and rosin technology, which is applied in the field of light-coloring rosin, can solve the problems of restricting product sales, environmental impact, and excessive content, and achieves the effects of low operating costs, low equipment requirements, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

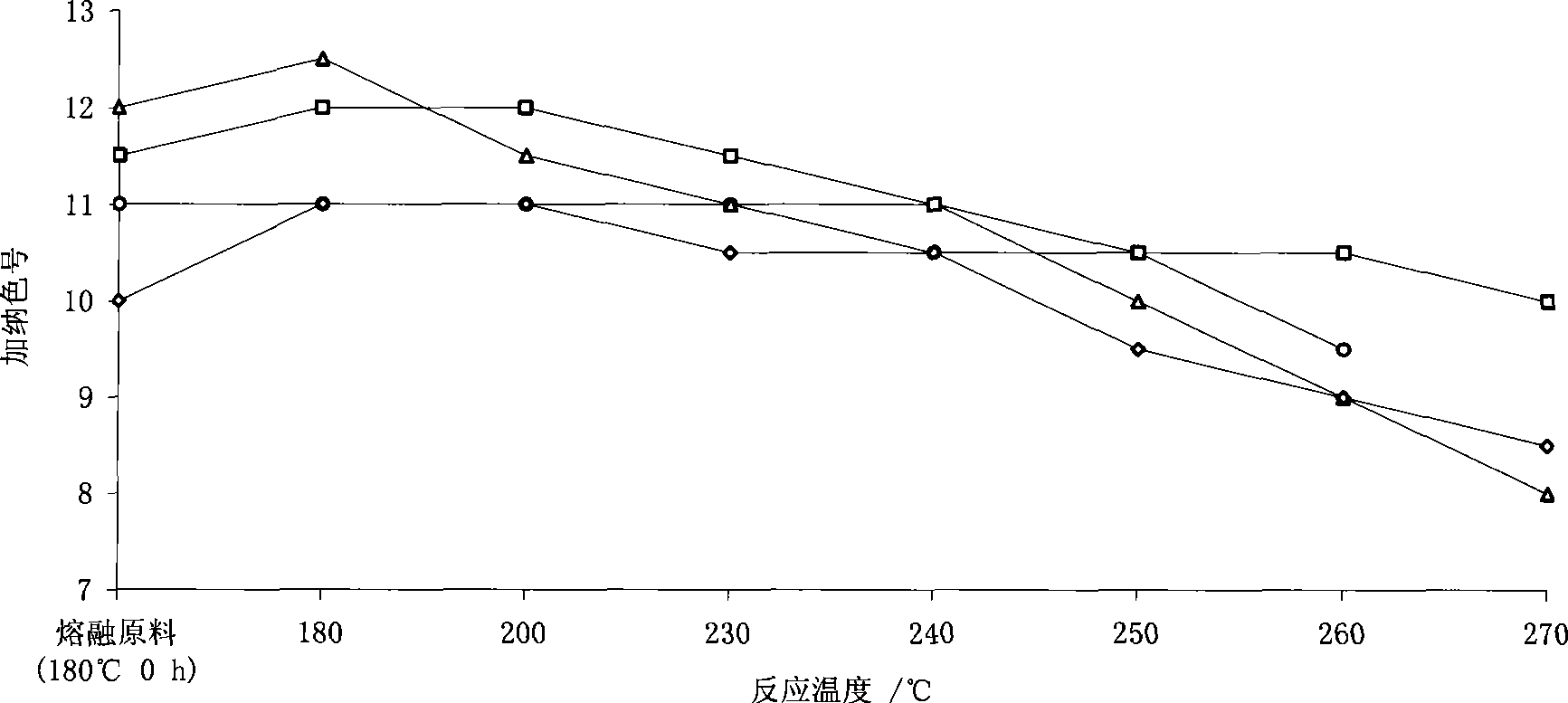

Embodiment 1

[0021] Process: (1) Weigh 50g of rosin into a 250mL four-necked flask, and install a thermometer, condenser tube (external tee and water pump or oil pump) and protective gas vent tube on the flask mouth. (2) Close the intake valve, turn on the water pump or oil pump to vacuum the pressure to 5-6kPa, remove the oxygen in the system as much as possible, repeat the above operation 3 times. Close the vacuum valve for the last time, pass the protective gas until the pressure inside the reaction system is slightly higher than that outside the system, then open the vacuum valve, and turn off the water pump or oil pump. Adjust the intake of protective gas, pass condensed water, and start heating. (3) When the temperature rises to about 110°C, mist is generated in the flask, and the rosin is partially melted at the same time. When the temperature rises to about 180°C, the rosin melts completely, and the temperature continues to rise to the set temperature (the temperature is controlle...

Embodiment 2~6

[0024] (1) Weigh 50g of pine pine rosin into a 250mL four-necked flask, and install a thermometer, condenser tube (external tee and water pump), and nitrogen vent tube on the flask mouth. (2) Close the intake valve, turn on the water pump to evacuate to 5-6kPa, remove the oxygen in the system as much as possible, and repeat the operation 3 times. Close the vacuum valve for the last time, pass nitrogen until the pressure inside the reaction system is slightly higher than that outside the system, then open the vacuum valve and turn off the water pump. Adjust the amount of nitrogen gas intake, pass condensed water, and start heating. (3) When the temperature rises to about 110°C, mist is generated in the flask, and the rosin is partially melted at the same time. When the temperature rises to about 180°C, the rosin melts completely, and when the temperature continues to rise to about 180°C, the rosin melts completely, and the temperature continues to rise to the set temperature (...

Embodiment 7~18

[0029] (1) Weigh 50g of masson pine rosin into a 250mL four-neck flask, and install a thermometer, condenser tube (external tee and water pump), and nitrogen vent tube on the flask mouth. (2) Close the intake valve, turn on the water pump to evacuate to 5-6kPa, remove the oxygen in the system as much as possible, and repeat the operation 3 times. Close the vacuum valve for the last time, pass nitrogen until the pressure inside the reaction system is slightly higher than that outside the system, then open the vacuum valve and turn off the water pump. Adjust the amount of nitrogen gas intake, pass condensed water, and start heating. (3) When the temperature rises to about 110°C, mist is generated in the flask, and the rosin is partially melted at the same time. When the temperature rises to about 180°C, the rosin melts completely, and when the temperature continues to rise to about 180°C, the rosin melts completely, and the temperature continues to rise to the set temperature (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com