Large-cantalever false-shunt aluminium section hot-extrusion die

A hot extrusion die and false shunting technology, applied in the direction of metal extrusion die, etc., can solve the problems of inability to meet the development requirements of this type of material, high production cost, difficult to achieve the predetermined output, etc., to achieve good surface quality, The effect of low production cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

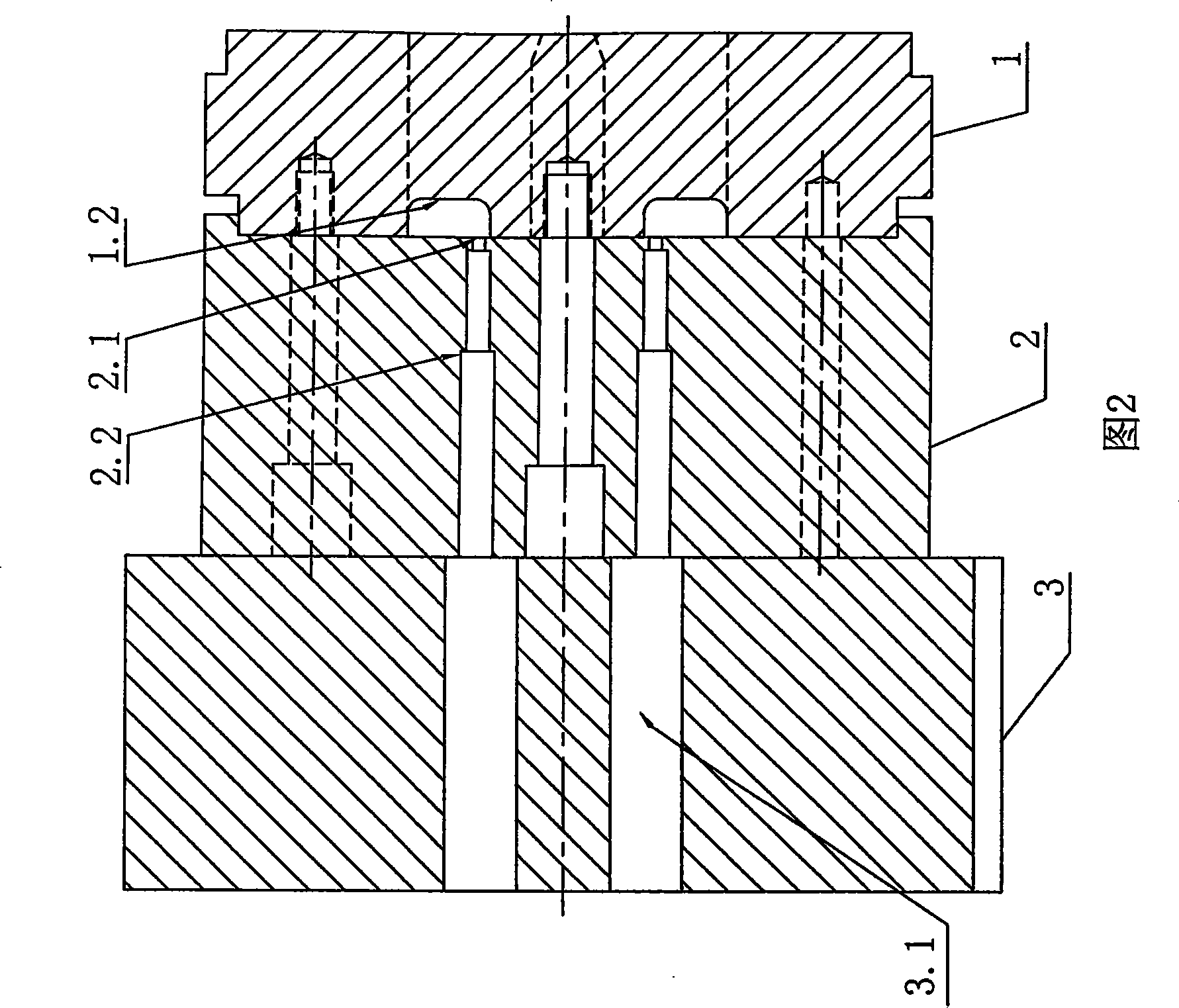

[0021] Referring to FIGS. 1-2 , the hot extrusion die for a large cantilever type false split aluminum profile according to the present invention is composed of a deflector 1 , a die face 2 and a die pad 3 . Two screws 6 and two pins 5 are used to connect the deflector 1 and the mold surface 2, and the outer circumference is tightly matched with a seam.

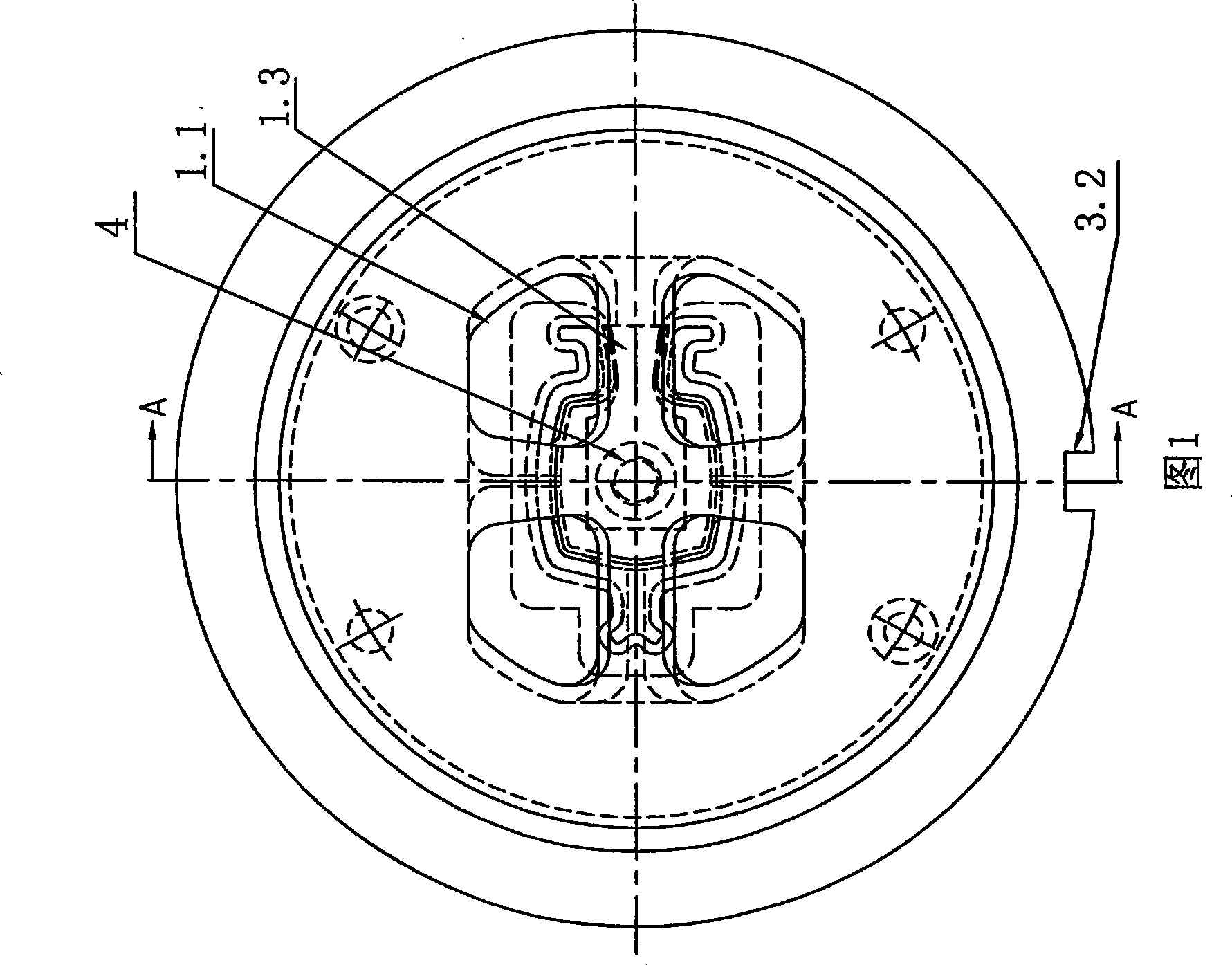

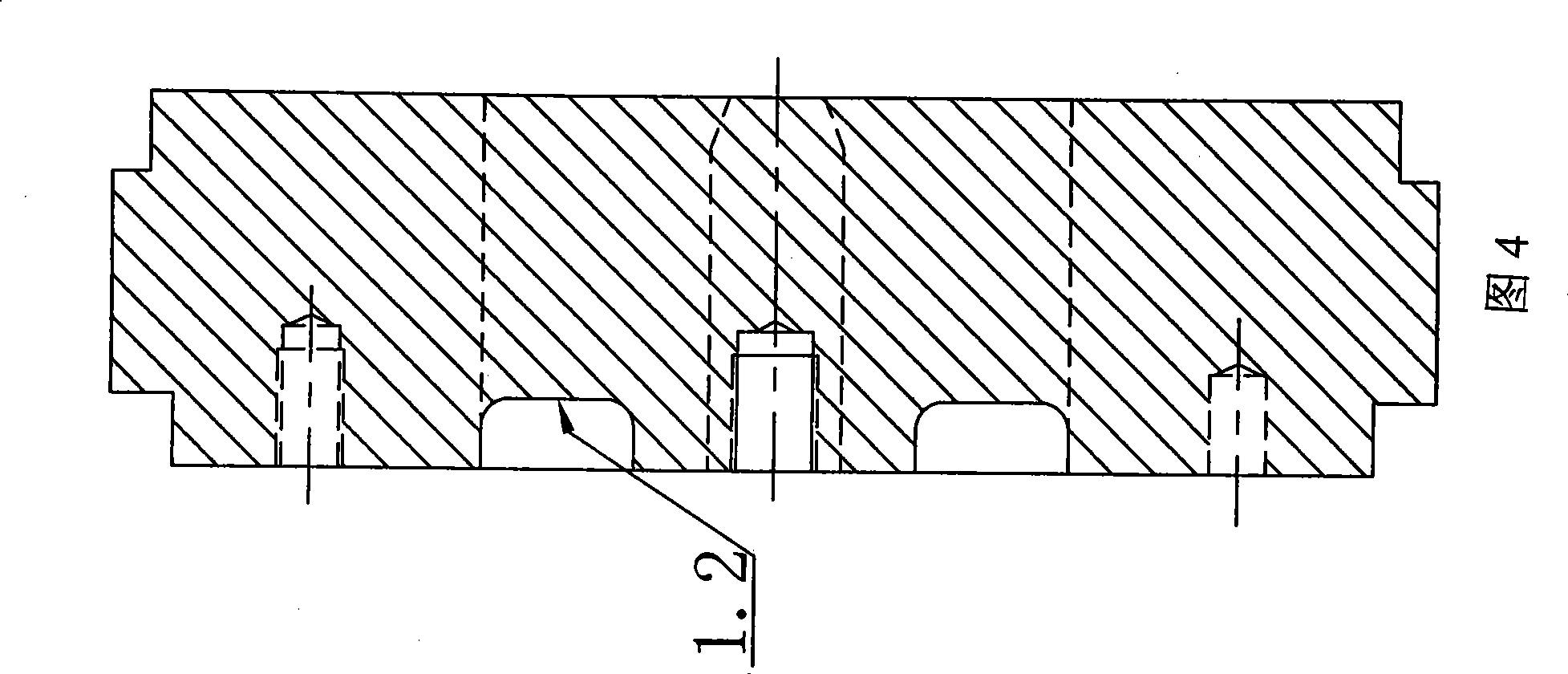

[0022] Referring to Figures 3 to 4, the feed surface of the deflector 1 is evenly distributed with several splitter holes 1.1 (there are four in the figure), the discharge surface of the deflector 1 is provided with sinking bridges 1.2, and the deflector 1 A dummy mold core 1.3 is provided at the center of the discharge surface of the dummy mold core 1.3, and a screw hole 1.4 is provided at the center of the dummy mold core 1.3, which is used to fix the large cantilever at the center of the mold surface.

[0023] Referring to Figures 5-6, the center of the die surface 2 is provided with a large cantilever 2.3, the feed surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com