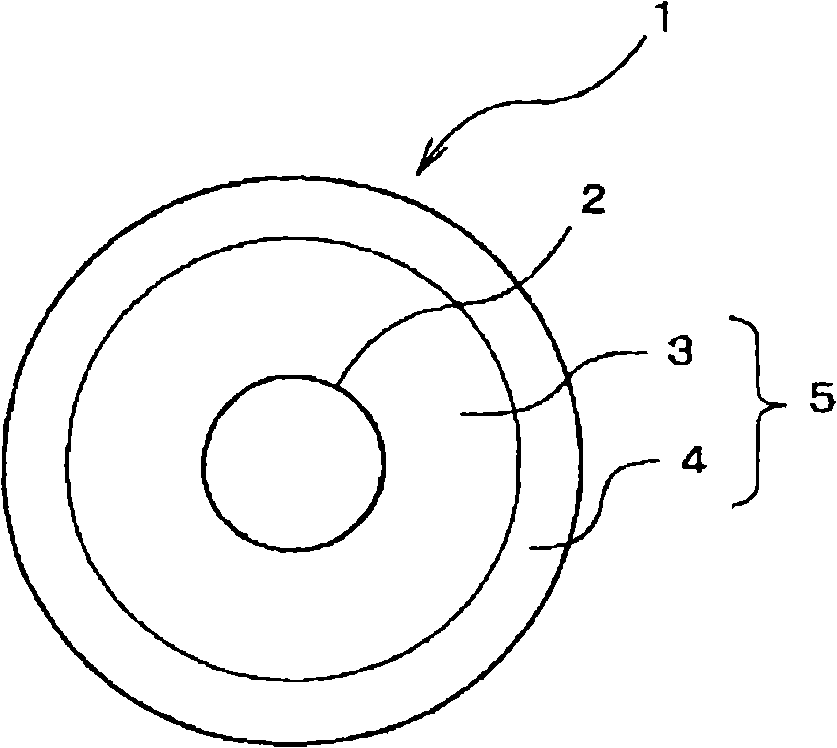

Non-halgen flame retardant wire

A wire and halogen technology, applied in the field of halogen-free flame-retardant wires, can solve the problems of mechanical properties and electrical properties decline, and achieve the effects of inhibiting mutual adhesion, improving tensile strength, and improving withstand voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Conductor: tinned annealed copper wire (AWG24, conductor structure 7 / 0.203, outer diameter 0.61mm)

[0036] ・Electric insulator: 100 parts by weight of EVA with a VA content of 70%

[0037] (Inner layer) 20 parts by weight of maleic anhydride modified EEA (modification rate 25%)

[0038] 180 parts by weight of magnesium hydroxide

[0039] Antioxidant 2 parts by weight

[0040] Layer thickness 0.42mm

[0041] ・Electrical insulator: 100 parts by weight of EVA with a VA content of 50%

[0042] (outer layer) 180 parts by weight of magnesium hydroxide

[0043] Antioxidant 2 parts by weight

[0044] Layer thickness 0.13mm

[0045] The electric wire of the above-mentioned Example 1 meets the prescribed flame retardancy standard (UL VW-1), and at the same time, the voltage resistance reaches 13kV (1 minute), the elongation rate is 170%, and the tensile strength is 11.5MPa, so it satisfies the prescribed v...

Embodiment 2

[0046] (Example 2: the thickness of the inner layer and the outer layer is the same)

[0047] Conductor: tinned annealed copper wire (AWG24, conductor structure 7 / 0.203, outer diameter 0.61mm)

[0048] ・Electric insulator: 100 parts by weight of EVA with a VA content of 70%

[0049] (Inner layer) Maleic anhydride modified EEA (modification rate 25%) 20 parts by weight

[0050] 180 parts by weight of magnesium hydroxide

[0051] Antioxidant 2 parts by weight

[0052] Layer thickness 0.27mm

[0053] ・Electrical insulating layer: 100 parts by weight of EVA with a VA content of 50%

[0054] (outer layer) 180 parts by weight of magnesium hydroxide

[0055] Antioxidant 2 parts by weight

[0056] Layer thickness 0.27mm

[0057] The electric wire of the above-mentioned Example 2 is an example when the thickness of the inner layer and the outer layer are made the same in Example 1, and it meets the prescribed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com