Well cleanout shunt

A diverter and positive washing technology, which is applied in the field of positive flushing diverters, can solve the problems of increased operating costs, large amount of well flushing fluid, and long flushing time, and achieve the effects of stable work, shortened operating time, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

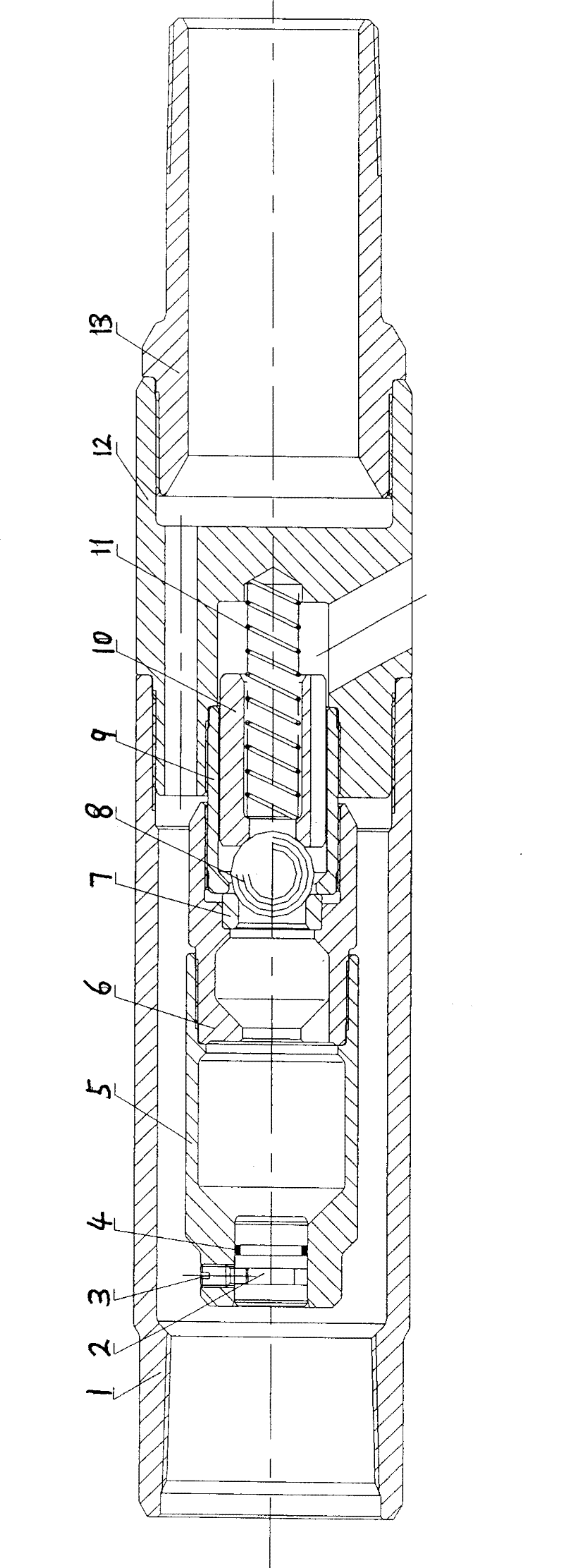

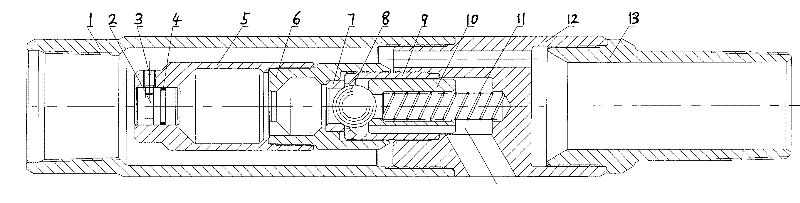

[0010] As shown in the figure, the present invention consists of an outer sleeve 1, a piston 2, a shear nail 3, an O-ring seal 4, a sealing joint 5, a valve cover 6, a valve seat 7, a valve ball 8, a pair of wires 9, and a spring sleeve 10) The spring 11, the shunt joint 12, and the lower joint 13 are composed. The outer sleeve 1 is connected with the outer diameter of the upper end of the shunt joint 12, the lower end of the shunt joint 12 is connected with the lower joint 13, and the inner diameter of the upper end of the shunt joint 12 is connected upwards to the wire 9 and the valve cover 6. , The sealing joint 5, the piston 2 is fixed in the inner space of the upper part of the sealing joint 5 by shear nails 3. The gap between the sealing joint 5 and the piston 2 is an O-ring 4, and the wire 9 and the valve cover 6 are pressed against the valve seat 7. The valve ball 8 is under the middle valve seat 7 of the aligning wire 9, and under the valve ball 8 is a spring sleeve 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com