Method for preparing hydrogen with Al alloy material at room temperature

A technology of alloy material and Al alloy, which is applied in the field of hydrogen preparation, can solve the problems of expensive, corrosive, powder preparation, storage, transportation and use, etc., and achieve the effect of easy storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

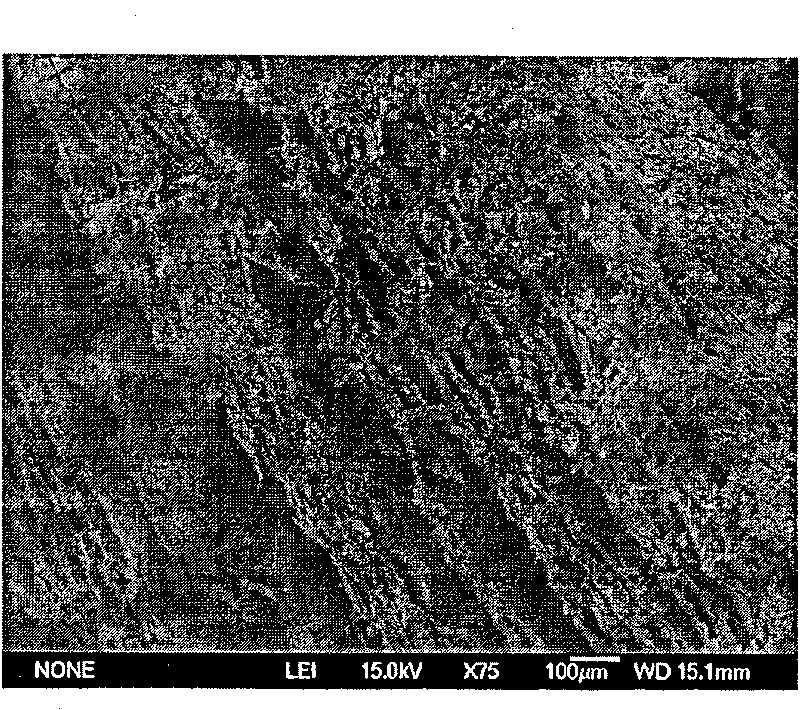

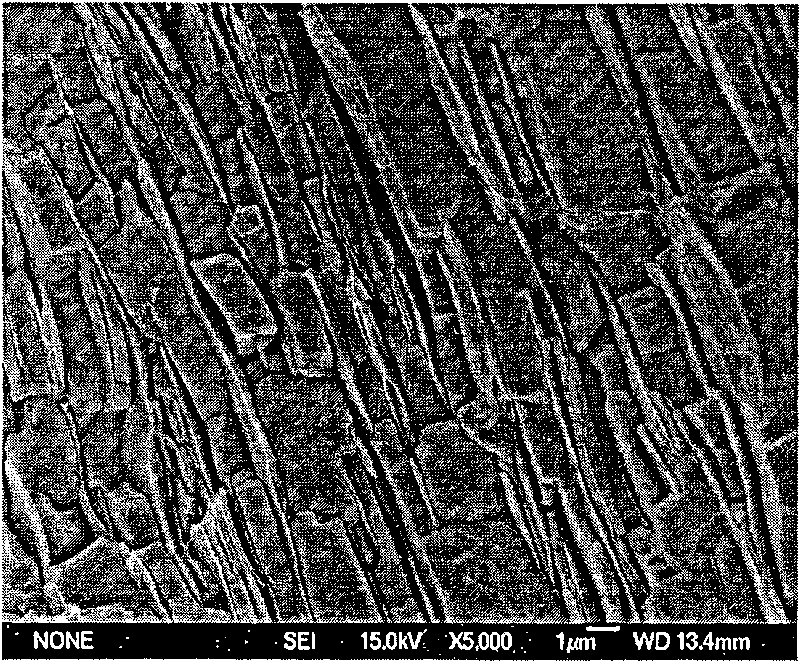

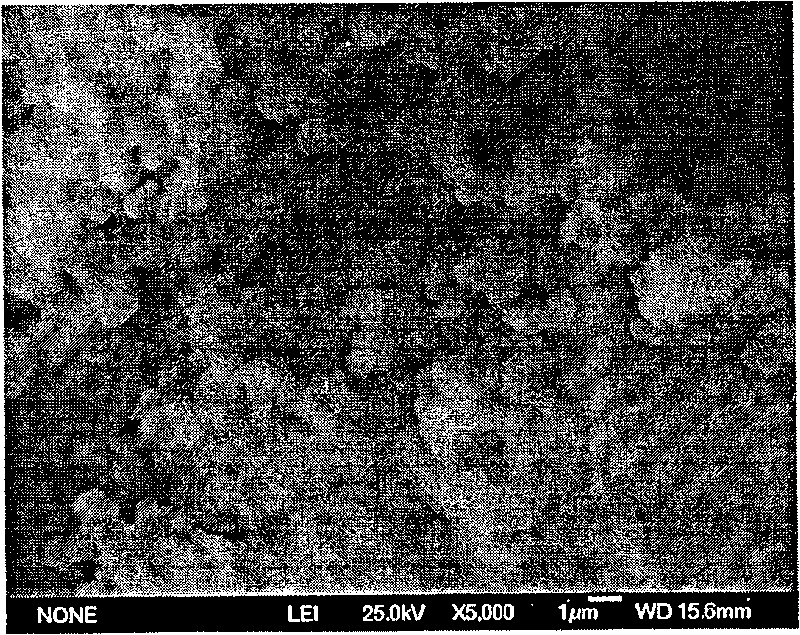

Image

Examples

example 1

[0026] A well-type resistance furnace is used to melt an Al-Sn alloy ingot with an Al content of 45wt% and the rest being Sn under the protection state of Ar gas at 800-1000°C. After the alloy ingot is cooled, it is directly rolled by the ordinary Al foil preparation process, the total rolling deformation rate is about 95%, and finally the Al-Sn alloy foil is obtained, and the thickness of the foil is 0.2mm. At room temperature, the hydrogen release per unit volume and unit mass of the alloy are 202KgH 2 / m 3 And 544L / Kg, the latter is equivalent to the ratio of hydrogen mass to alloy mass is 4.86%, close to 5wt% (excluding water mass), and the hydrogen production per unit volume of material can reach 200KgH 2 / m 3 , which contains more hydrogen than general hydrogen storage materials. If the alloy of the same composition has not undergone this kind of machining treatment, the reaction speed with water is very slow and cannot be applied.

example 2

[0028] A well-type resistance furnace is used to melt an Al-Sn alloy ingot with an Al content of 15wt% and the rest being Sn under the protection state of Ar gas at 800-1000°C. After the alloy ingot is cooled, it is directly rolled by the ordinary Al foil preparation process, the total rolling deformation rate is about 95%, and finally the Al-Sn alloy foil is obtained, and the thickness of the foil is 0.3mm. At room temperature, the hydrogen released per unit volume and unit mass of the alloy are 77KgH 2 / m 3 and 150L / Kg. If the alloy of the same composition has not undergone this kind of machining treatment, the reaction speed with water is very slow and cannot be applied.

example 3

[0030] A well-type resistance furnace is used to melt an Al-Sn alloy ingot with an Al content of 60wt% and the rest being Sn under the protection state of Ar gas at 800-1000°C. After the alloy ingot is cooled, it is directly rolled by the ordinary Al foil preparation process, the total rolling deformation rate is about 95%, and finally the Al-Sn alloy foil is obtained, and the thickness of the foil is 0.2mm. At room temperature, the hydrogen release per unit volume and unit mass of the alloy are 91KgH 2 / m 3 and 281L / Kg. If the alloy of the same composition has not undergone this kind of machining treatment, the reaction speed with water is very slow and cannot be applied.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com