Molecular sieve granulator

A ball forming machine and molecular sieve technology, applied in the field of molecular sieves, can solve the problems of frequent replacement of parts, high noise, and large maintenance, and achieve the effects of increasing gear life and bearing capacity, reducing noise, and high ball forming efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

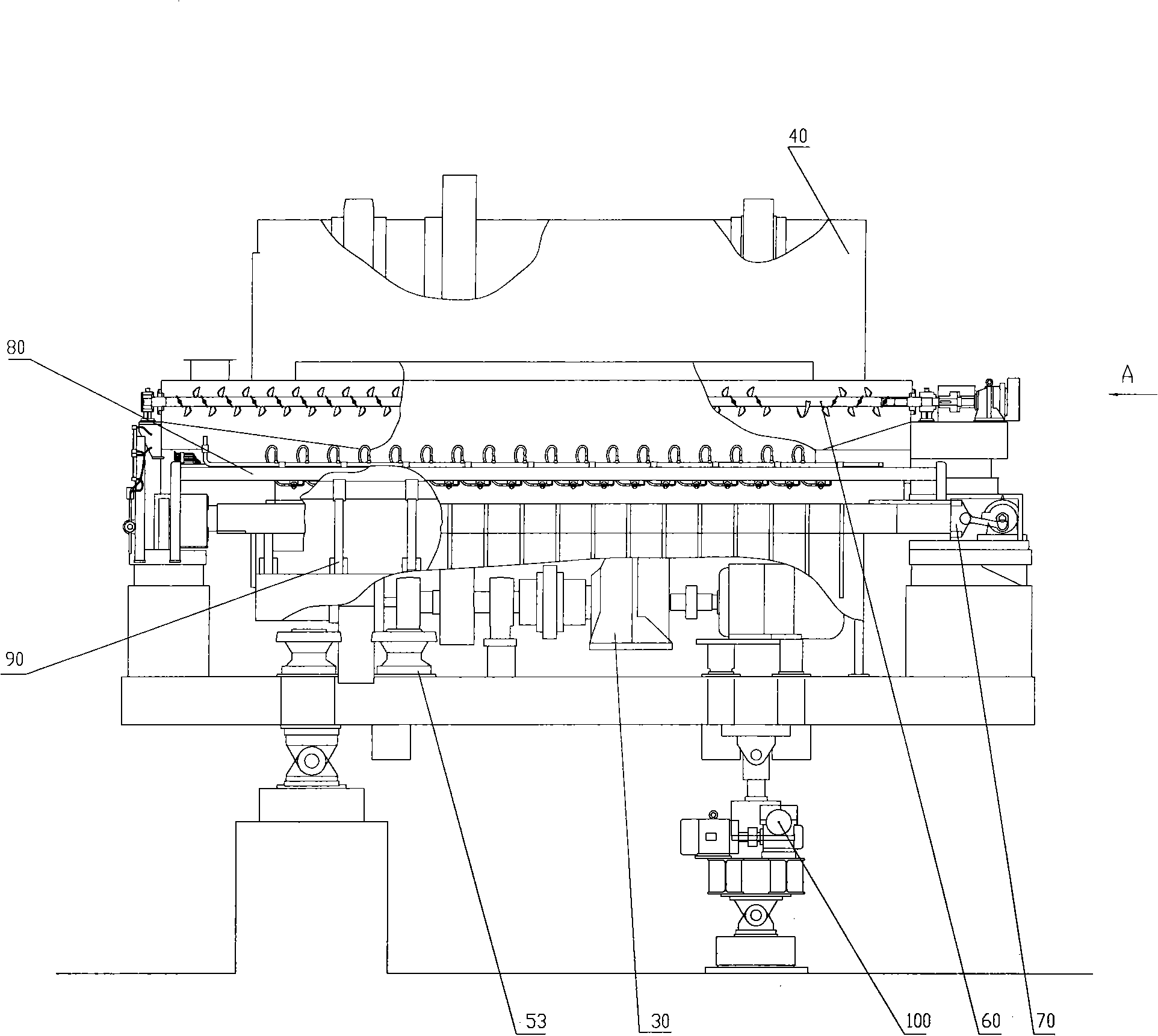

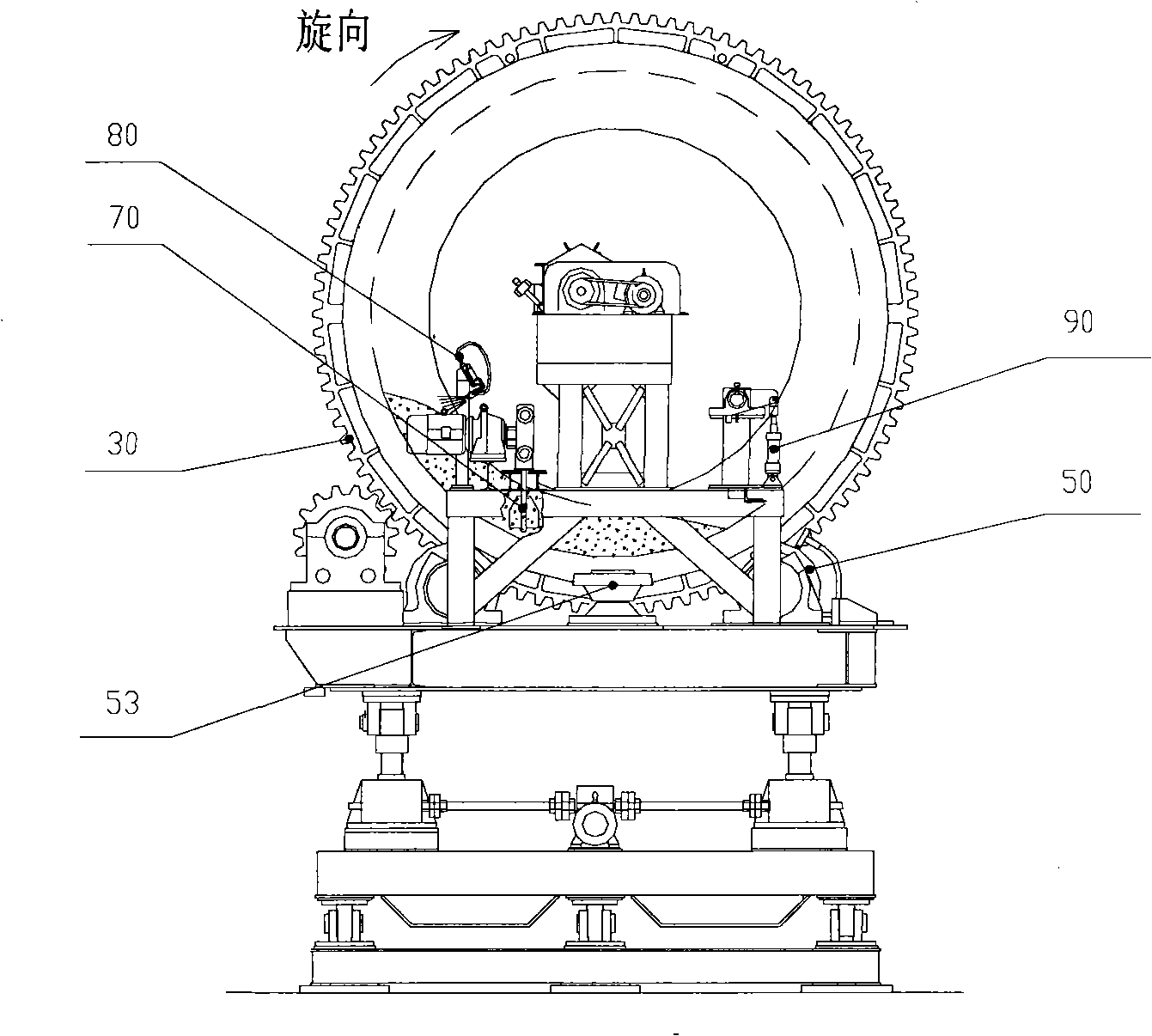

[0039] Such as figure 1 , figure 2 The molecular sieve ball forming machine shown includes a power transmission part 30, a cylinder part 40, a supporting wheel device 50, a wheel stop device 53, a screw conveyor 60, a rake part 70, a water spray device 80, a discharge scraper device 90, and a lifting device.装置100。 Device 100.

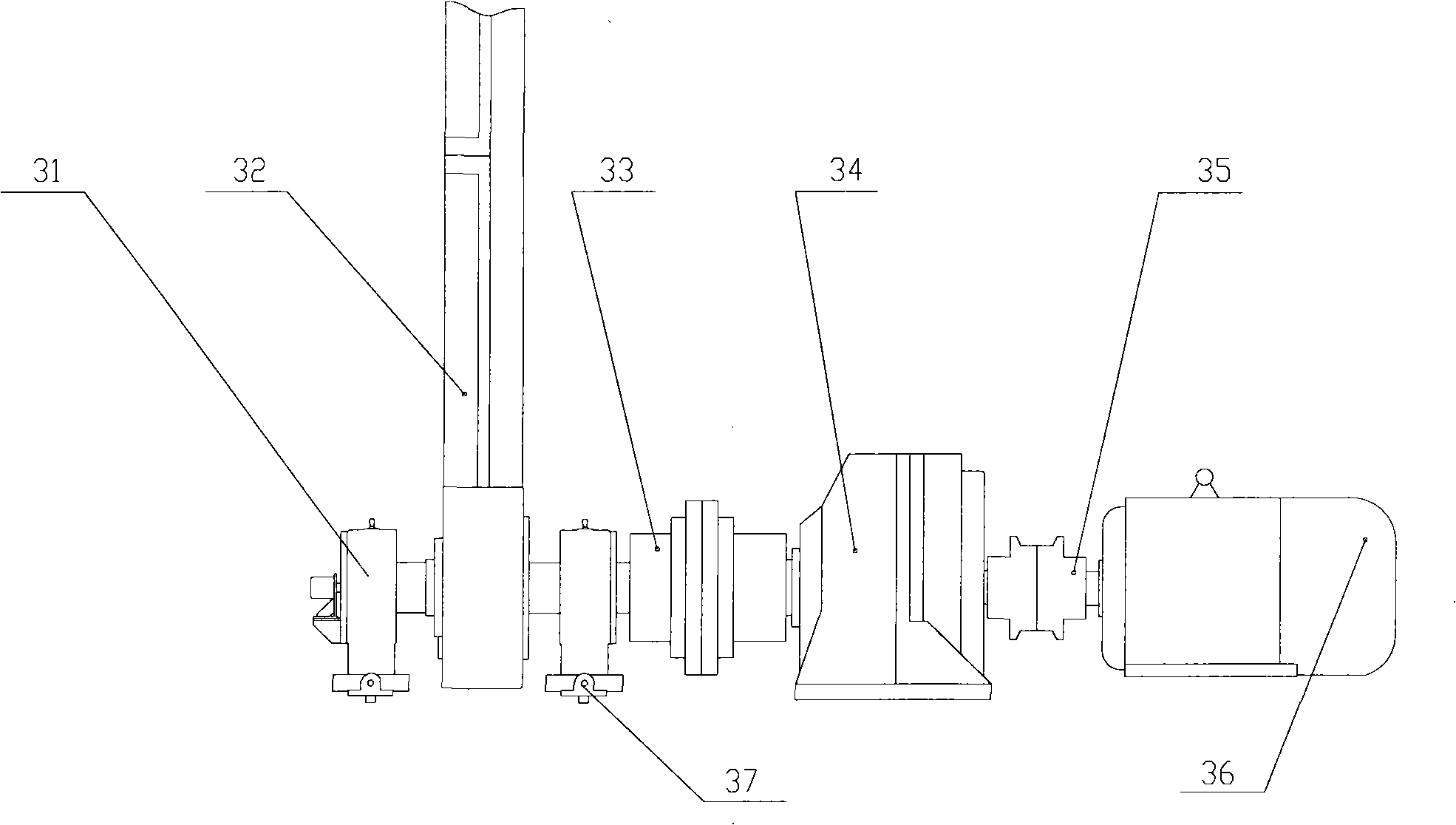

[0040] Such as Figure 3A , Figure 3B , The power transmission part 30 includes a main motor 36, a main motor reducer 34, a large gear 32, a small gear set 31 and two couplings 33, 35. The main motor 36 is connected to the main motor reducer 34 through the second coupling 35, the main motor reducer 34 is connected to the small gear set 31 through the first coupling 33, and the small gear set 31 meshes with the large gear 32. An adjustment seat 37 is provided at the bottom of the pinion gear group 31. The large gear 32 adopts a large displacement gear, which can increase the life and bearing capacity of the gear; the small gear adopts a nylon gear, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com