Wet desulfurization dust-removing device and processing method thereof

A dust removal device and wet desulfurization technology, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as insufficiently compact structure ratio, high investment cost, and large floor area, and achieve compact structure and high processing efficiency. The effect of being tall and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

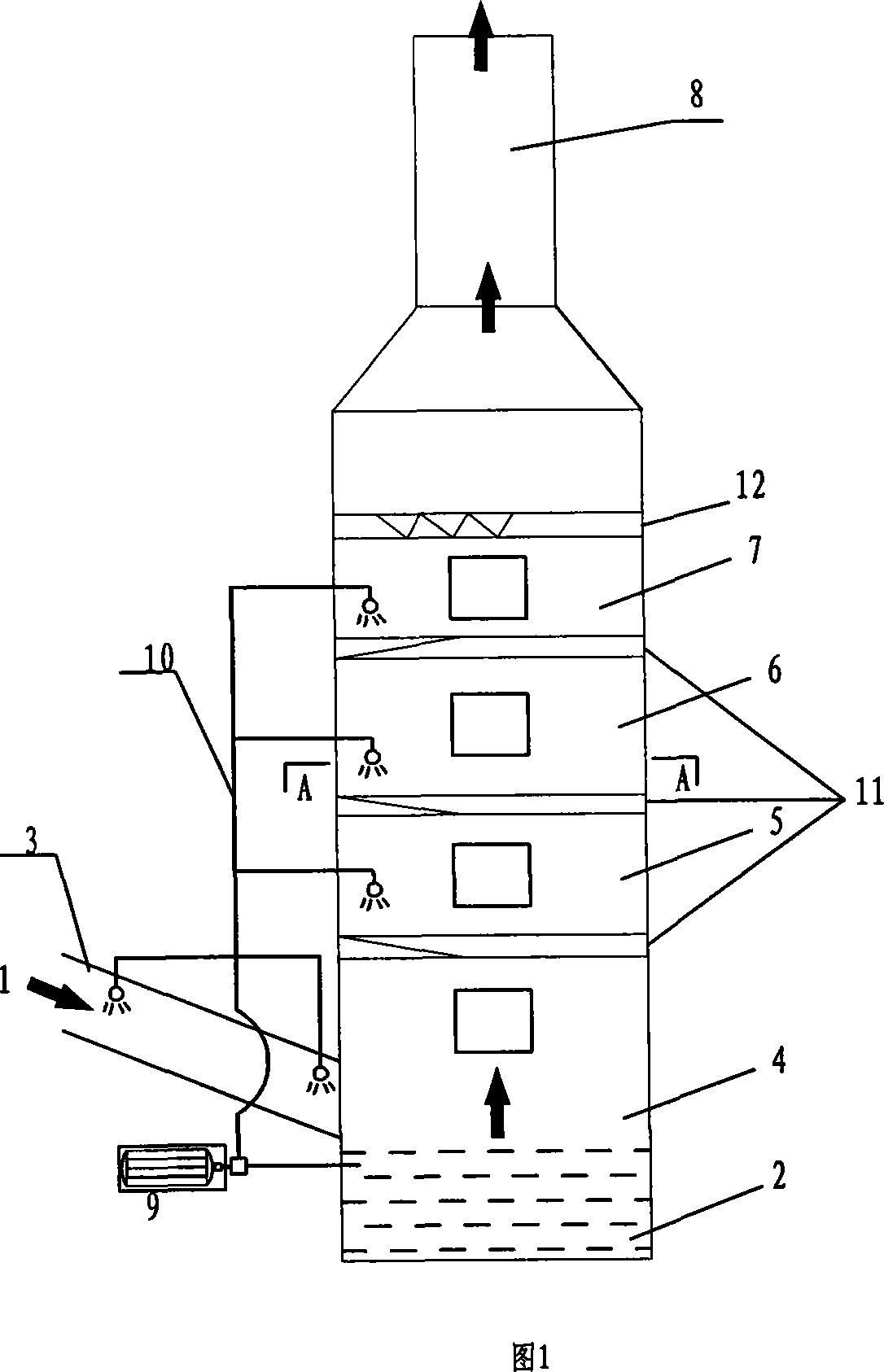

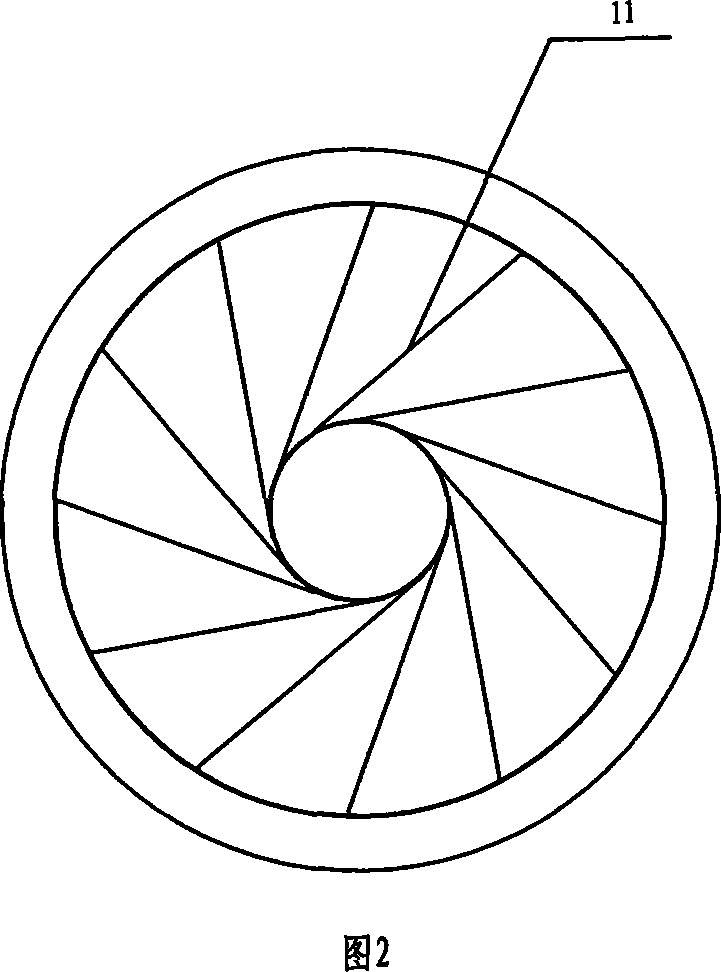

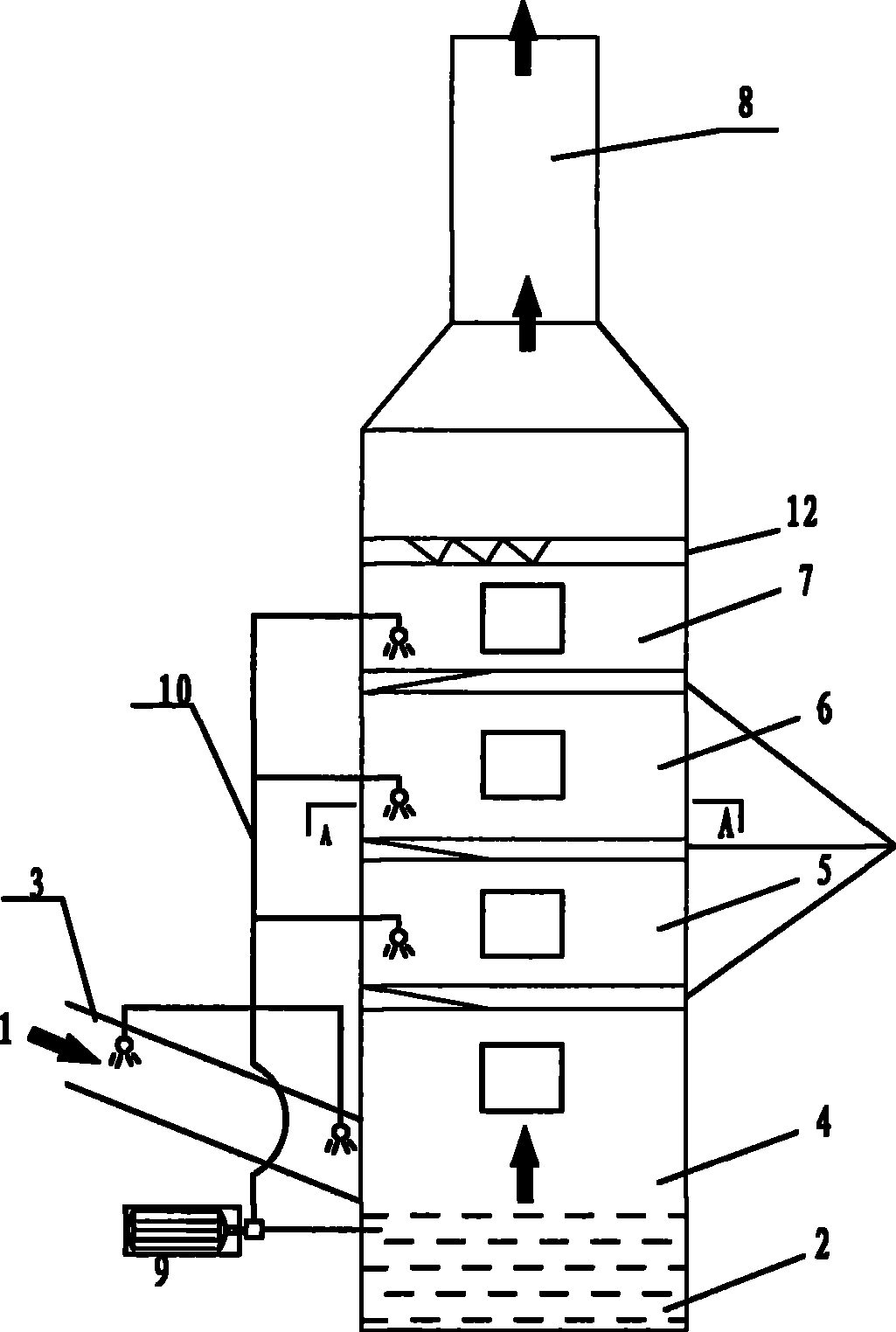

[0020] Such as Figure 1-2 As shown, the wet desulfurization and dust removal device of the utility model is an integrated steel structure tower body, which is lined with glass fiber reinforced plastics and granite chips for anticorrosion and wear resistance. The special parts are made of 316L stainless steel. , the exhaust gas 1 is introduced into the pretreatment chamber 3 on one side of the tower body, the tower body also includes a discharge circulation system, and the discharge circulation system includes a circulating liquid 2 arranged at the base of the tower and a chimney 8 at the top of the tower; The following processing structure parts are provided: self-excitation chamber 4, atomization spray chamber 5, gas-liquid separation chamber 6 and demisting chamber 7; water pump 9, water pipe 10 and shower are connected to each processing chamber respectively through the bottom of the tower body Communication, that is, the water pump 9 enters each treatment chamber (3, 4, 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com