Golf head easy to weld counterweight device and production method thereof

A technology of golf head and counterweight device, which is applied to golf balls, golf clubs, rackets, etc., and can solve problems such as inability to produce resonance sound, upward movement, and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

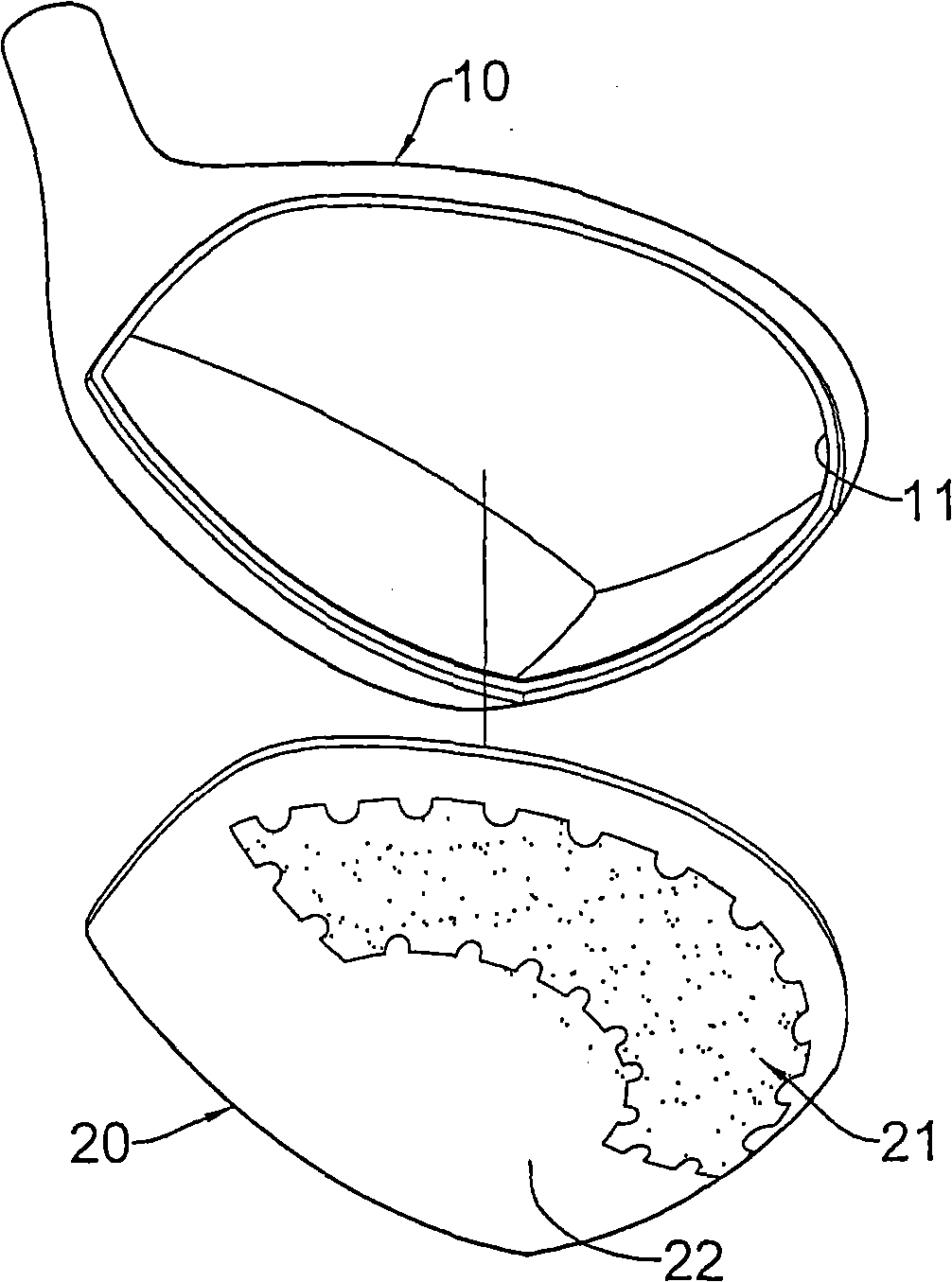

[0041] see figure 1 , 2 , 3, the golf head that is easy to weld the weight device provided by the present invention includes a ball head body 10 and a weight plate body 20 with double specific gravity. The bottom of the ball head body 10 is provided with a welding port 11 for connecting The counterweight plate body 20 of double specific gravity is welded.

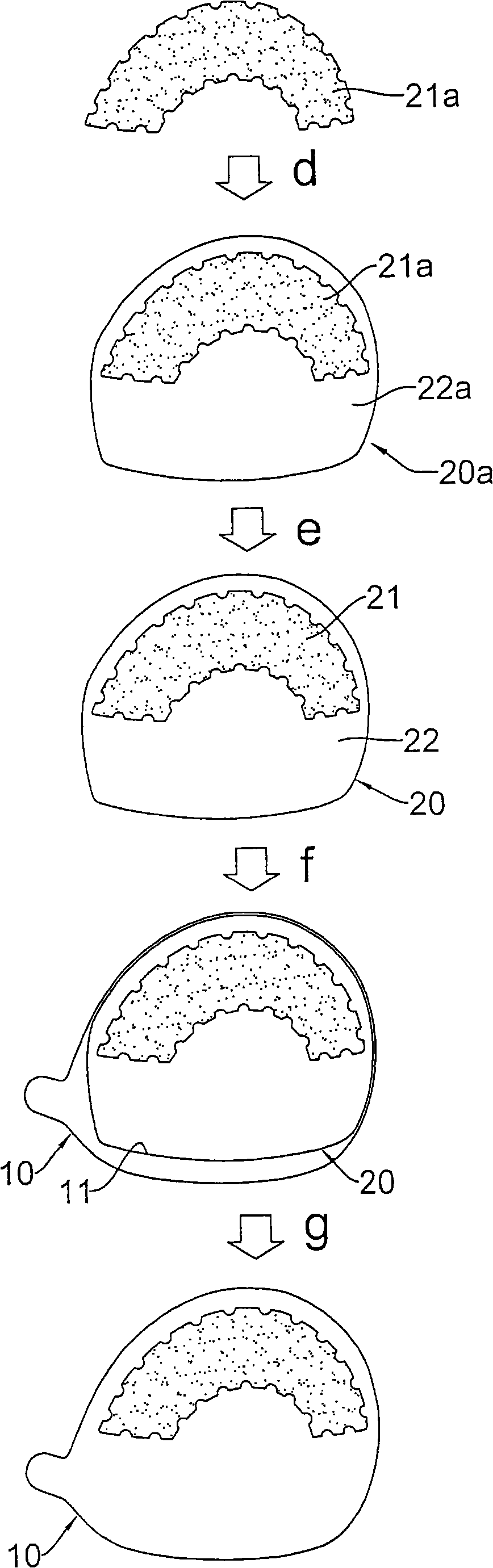

[0042] The counterweight plate body 20 of double specific gravity is configured on the welding port 11 by its outer periphery, and then welded at the junction. The counterweight plate body 20 of this double specific gravity includes a high specific gravity alloy part 21, and a high specific gravity alloy part The metal part 22 on the periphery of the metal part 21, the design of continuous wavy lines between the periphery of the high specific gravity alloy part 21 and the metal part 22, not only enables the two different materials to be firmly combined, but also creates different visual aesthetics. The high specific gravi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com