Silica-gel coating catheters and production technique thereof

A urinary catheter and silica gel technology, applied in the direction of catheters, coatings, and other medical devices, can solve the problems of waste of manpower and material resources, bacterial infection, and environmental damage, and achieve the effects of avoiding damage, high permeability, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A silicone-coated urinary catheter, which is composed of a tube fork 7, a tube body 8 and a spherical membrane 4 in sequence, wherein the tube fork 7 is composed of a rubber fork 2 and a funnel 1, and one end of the rubber fork 2 meets the funnel 1 At the connection with the tube body 8, the rubber fork 2, the funnel 1 and the tube body 8 form a Y shape, and the other end of the tube body 8 away from the funnel 1 is provided with a drain hole 5, and the tube body 8 is provided with a balloon part 6, The balloon part 6 is located between the drain hole 5 and the funnel 1 and close to the tube body of the drain hole 5, the balloon 4 is provided with an inflation hole 9, and the balloon membrane 4 is set on the balloon inflation hole 9, and the entire urinary catheter The outer surface of the tube is covered with a silicone coating. A rubber stopper 3 is provided on the rubber fork, and the rubber stopper is located at the other end away from the connection between the rub...

Embodiment 2

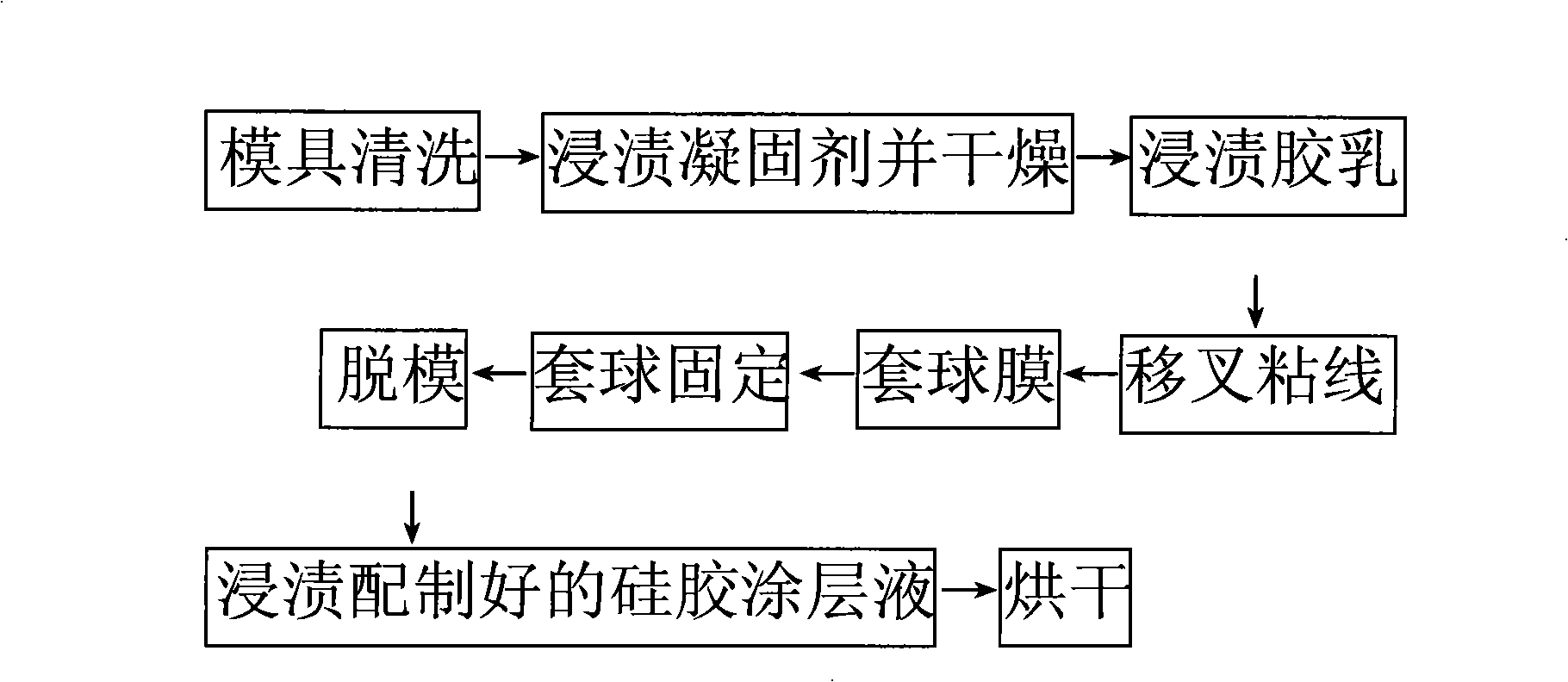

[0019] A method for preparing a silica gel-coated urinary catheter, the preparation steps are: cleaning the mold: cleaning impurities on the mold at room temperature; impregnating the mold with a coagulant: immersing the mold in the coagulant, taking it out and drying it until no coagulant drips , dry the mold coated with coagulant at 60°C for 20 minutes; latex dipping: dip the dried mold into latex to form the first latex layer on the mold, and the total latex solid mass concentration in the first layer of latex is 48 %; shifting fork and sticking wire: sending the glue wire into the ball capsule position of the catheter through the moving fork sticking process, and then dipping and sealing the wire latex. The total solid mass concentration of latex in the sealing wire latex is 48%, and the skeined wire is sealed in the In the middle of the first layer and the second layer of latex, the dipping time is 50 seconds, and the mold after dipping is dried at 55°C for 1 hour, and the...

Embodiment 3

[0021]A method for preparing a silica gel-coated urinary catheter, the preparation steps are: cleaning the mold: cleaning impurities on the mold at room temperature; impregnating the mold with a coagulant: immersing the mold in the coagulant, taking it out and drying it until no coagulant drips , dry the mold coated with coagulant at 65°C for 20 minutes; latex dipping: dip the dried mold into latex to form the first latex layer on the mold, and the total latex solid mass concentration in the first layer of latex is 50 %; shifting fork and sticking wire: sending the rubber wire into the ball capsule of the catheter through the shifting fork and sticking process, and then dipping and sealing the wire latex. In the middle of the first layer and the second layer of latex, the dipping time is 55 seconds. The mold after dipping is dried at 60°C for 1 hour, and then the product is taken out of the oven and cut holes are used as the inflation holes of the balloon. The part is between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com