Method for producing 2-tertiary butyl-p-cresol and 6-tertiary butyl-m-cresol

A technology of tert-butyl and p-cresol, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of high cost, high price, high selling price, etc., and achieve the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

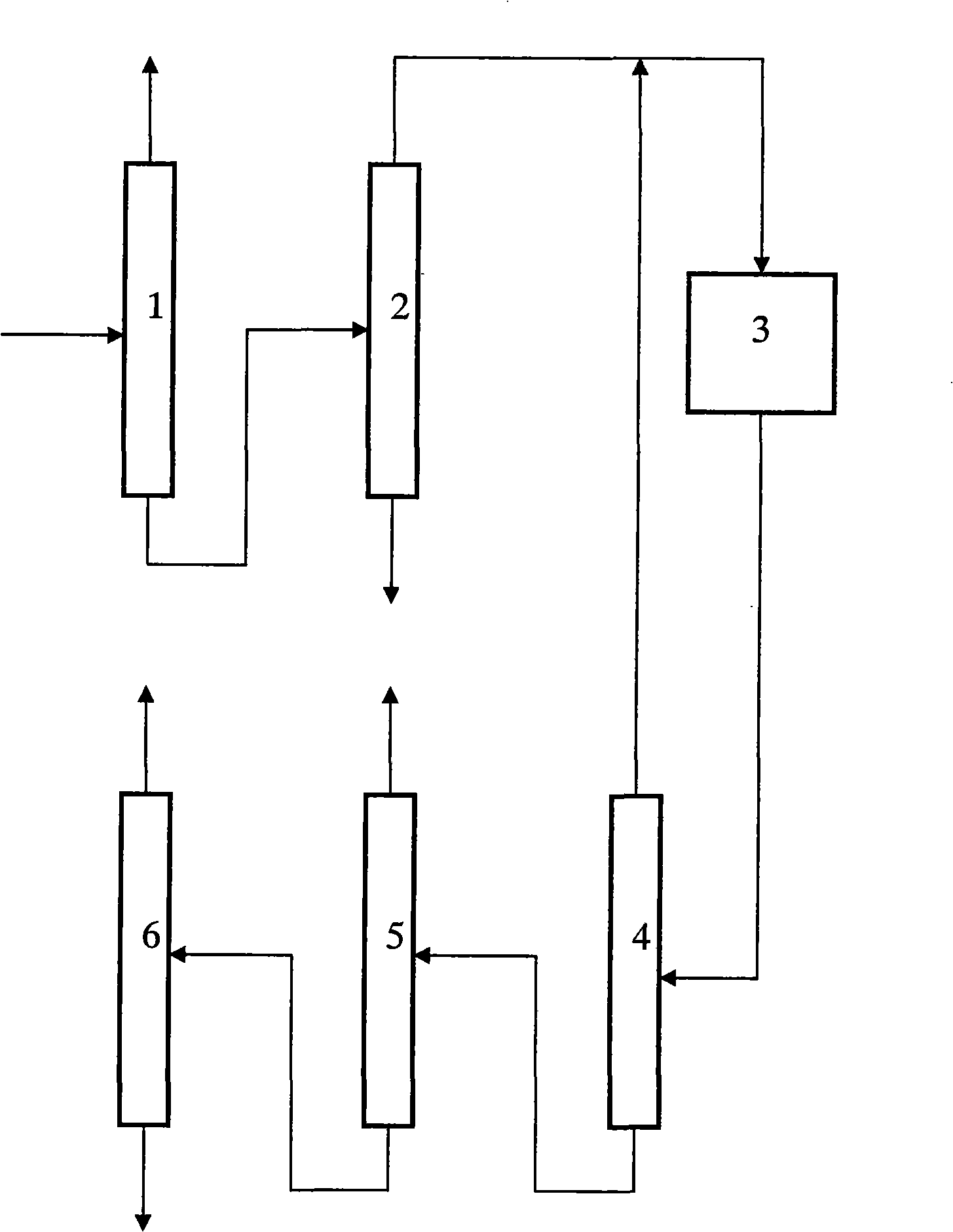

Image

Examples

Embodiment 1

[0022] The mixed cresol that contains 14% (W / W) p-cresol and 16% (W / W) m-cresol enters the rectification column 1 (1), and the group with boiling point before the p- and m-cresol boiling point is distilled out from the top of the tower points, p-, m-cresol and components with boiling point after that are discharged from the bottom of the tower. The temperature at the top of rectification column 1 is 90°C, the temperature at the bottom of the column is 130°C, and the pressure at the top of the column is 0.003MPa.

[0023] The components discharged from the bottom of the rectification tower 1 enter the rectification tower 2 (2), and the p- and m-cresols with a total content of 95.0% (W / W) are distilled from the top of the rectification tower 2, which is the refined mixed cresol, Heavies are discharged from the bottom of the column. The temperature at the top of the rectification tower 2 is 100°C, the temperature at the bottom of the tower is 140°C, and the pressure at the top o...

Embodiment 2

[0029] The mixed cresol that contains 38% (W / W) p-cresol and 26% (W / W) m-cresol enters the rectification column 1 (1), and the group with the boiling point before the p- and m-cresol boiling point is distilled out from the top of the tower points, p-, m-cresol and components with boiling point after that are discharged from the bottom of the tower. The temperature at the top of rectification tower 1 is 195°C, the temperature at the bottom of the tower is 230°C, and the pressure at the top of the tower is normal pressure.

[0030] The components discharged from the bottom of the rectification tower 1 enter the rectification tower 2 (2), and the p- and m-cresols of the total content of 90% (W / W) are distilled from the top of the rectification tower 2, which is the refined mixed cresol, Heavies are discharged from the bottom of the column. The temperature at the top of rectification tower 2 is 205° C., the temperature at the bottom of the tower is 245° C., and the pressure at th...

Embodiment 3

[0036] The mixed cresol that contains 38% (W / W) p-cresol and 26% (W / W) m-cresol enters the rectification column 1 (1), and the group with the boiling point before the p- and m-cresol boiling point is distilled out from the top of the tower points, p-, m-cresol and components with boiling point after that are discharged from the bottom of the tower. The temperature at the top of rectification tower 1 is 195°C, the temperature at the bottom of the tower is 230°C, and the pressure at the top of the tower is normal pressure.

[0037] The components discharged from the bottom of the rectification tower 1 enter the rectification tower 2 (2), and the p- and m-cresols of the total content of 90% (W / W) are distilled from the top of the rectification tower 2, which is the refined mixed cresol, Heavies are discharged from the bottom of the column. The temperature at the top of rectification tower 2 is 205° C., the temperature at the bottom of the tower is 245° C., and the pressure at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com