Concrete station and method for dedusting by stages according to operation process

A technology for concrete and mixing plants, which is applied in chemical instruments and methods, mixing plants, clay preparation devices, etc., can solve the problems of insufficient dust collection pressure, low dust removal effect, and bulky volume, so as to reduce the volume and occupied space, Guaranteed air volume and air pressure, good dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] best practice

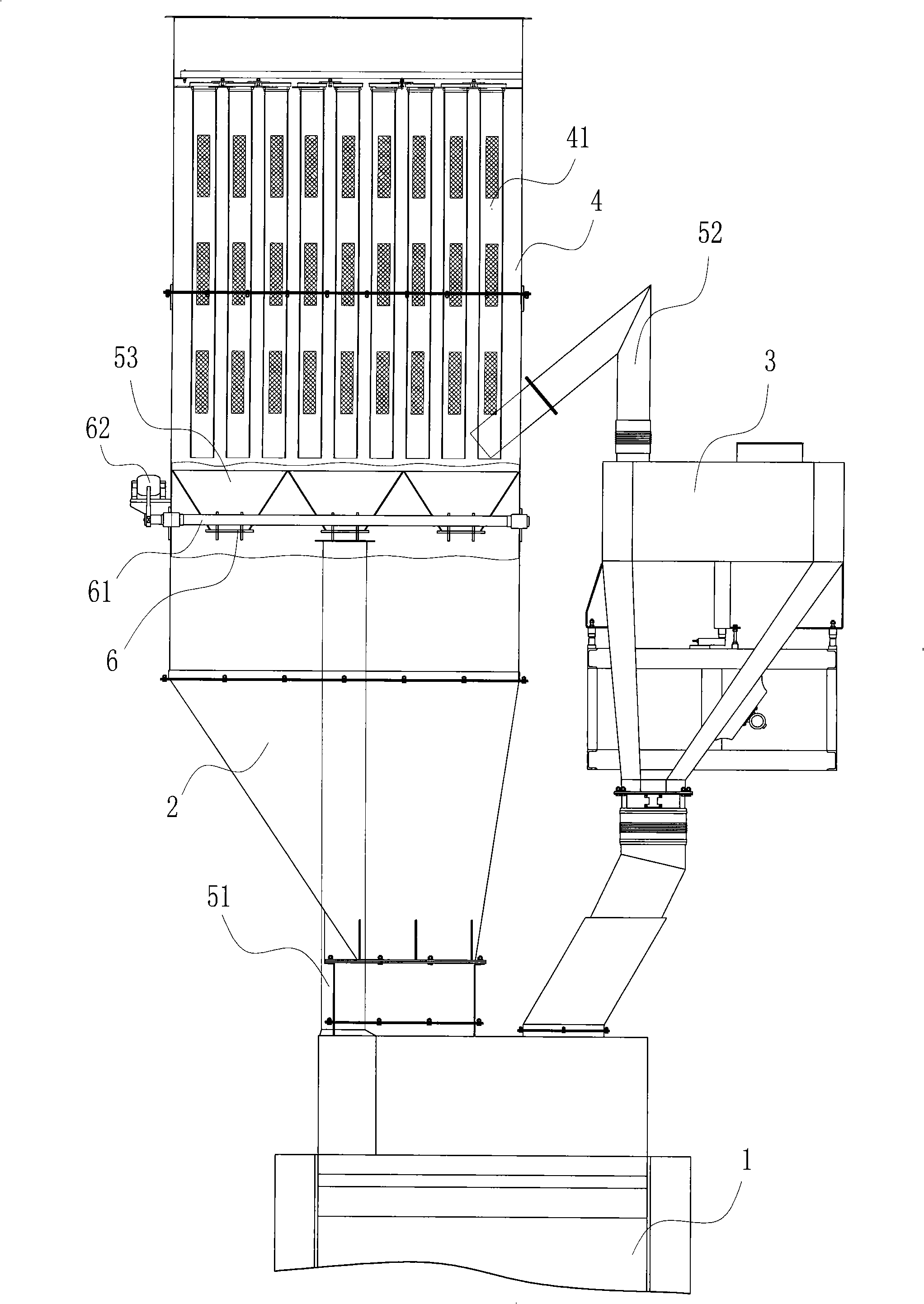

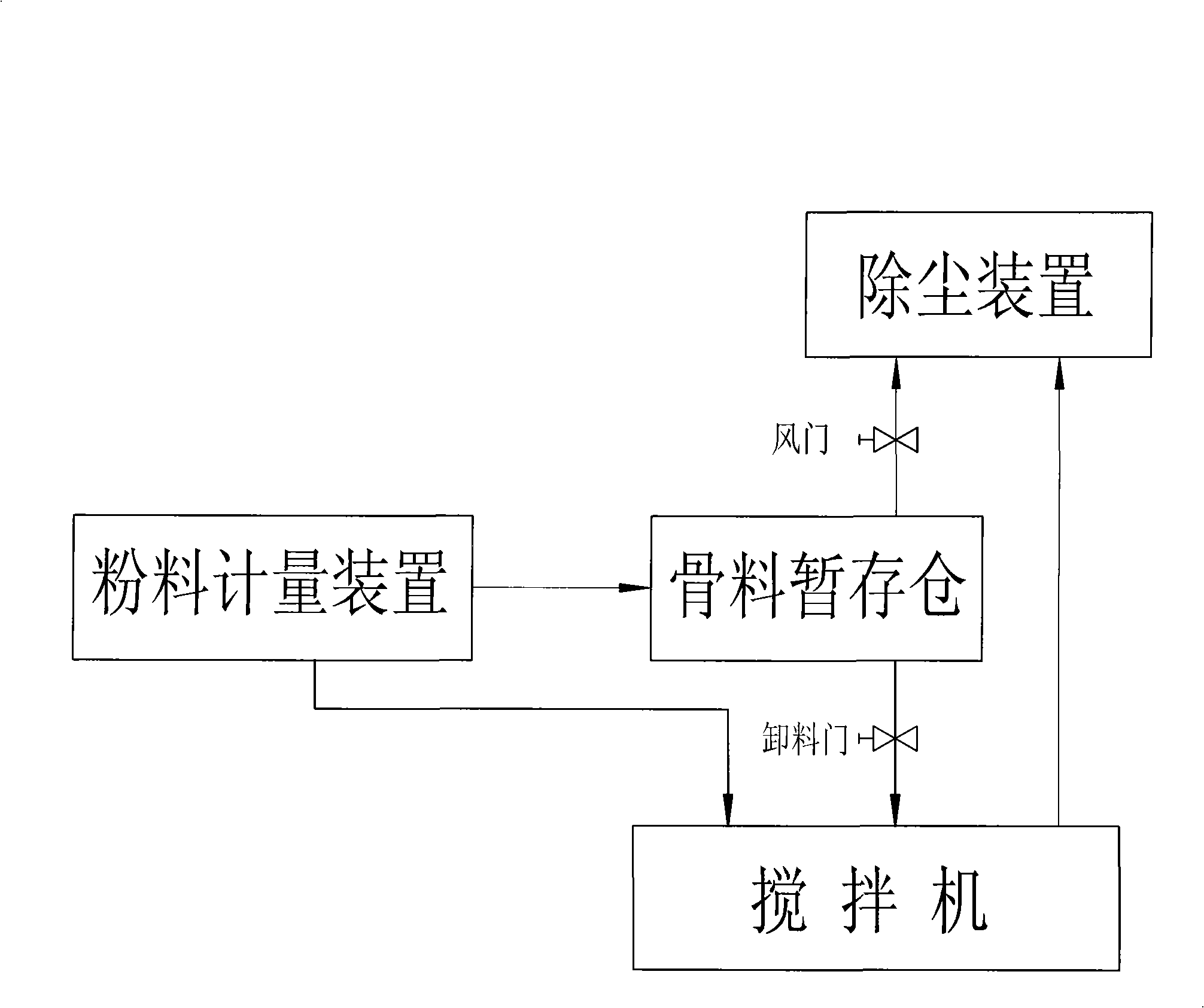

[0018] figure 1 The main tower part of the concrete mixing plant provided by the present invention is shown, and the main tower includes a mixer 1 , an aggregate temporary storage bin 2 , a powder metering device 3 , and a dust removal device 4 . The aggregate temporary storage bin 2 and the powder metering device 3 are installed above the mixer 1, and both have a material inlet and a material outlet. The opening / closing feeding gate is provided at the feeding opening of the aggregate temporary storage bin 2, and the opening / closing of the feeding gate is controlled by a driving mechanism. The mixer 1 has an aggregate inlet and a powder inlet, and communicates with the aggregate temporary storage bin 2 and the outlet of the powder metering device 3 through pipelines respectively. There are a plurality of dust removers 41 arranged vertically in the dust removal device 4 , and various existing products can be used for the dust removers 41 , whose structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com