Special purpose grinder for piston ring helical supporting spring head face

A spiral support spring and special grinding machine technology, which is applied to grinding machines, machine tools suitable for grinding workpiece edges, and machine tools suitable for grinding workpiece planes, etc. It can solve problems such as unstable product quality, low safety, and difficult control , to achieve good product quality consistency, improve processing efficiency, and avoid processing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

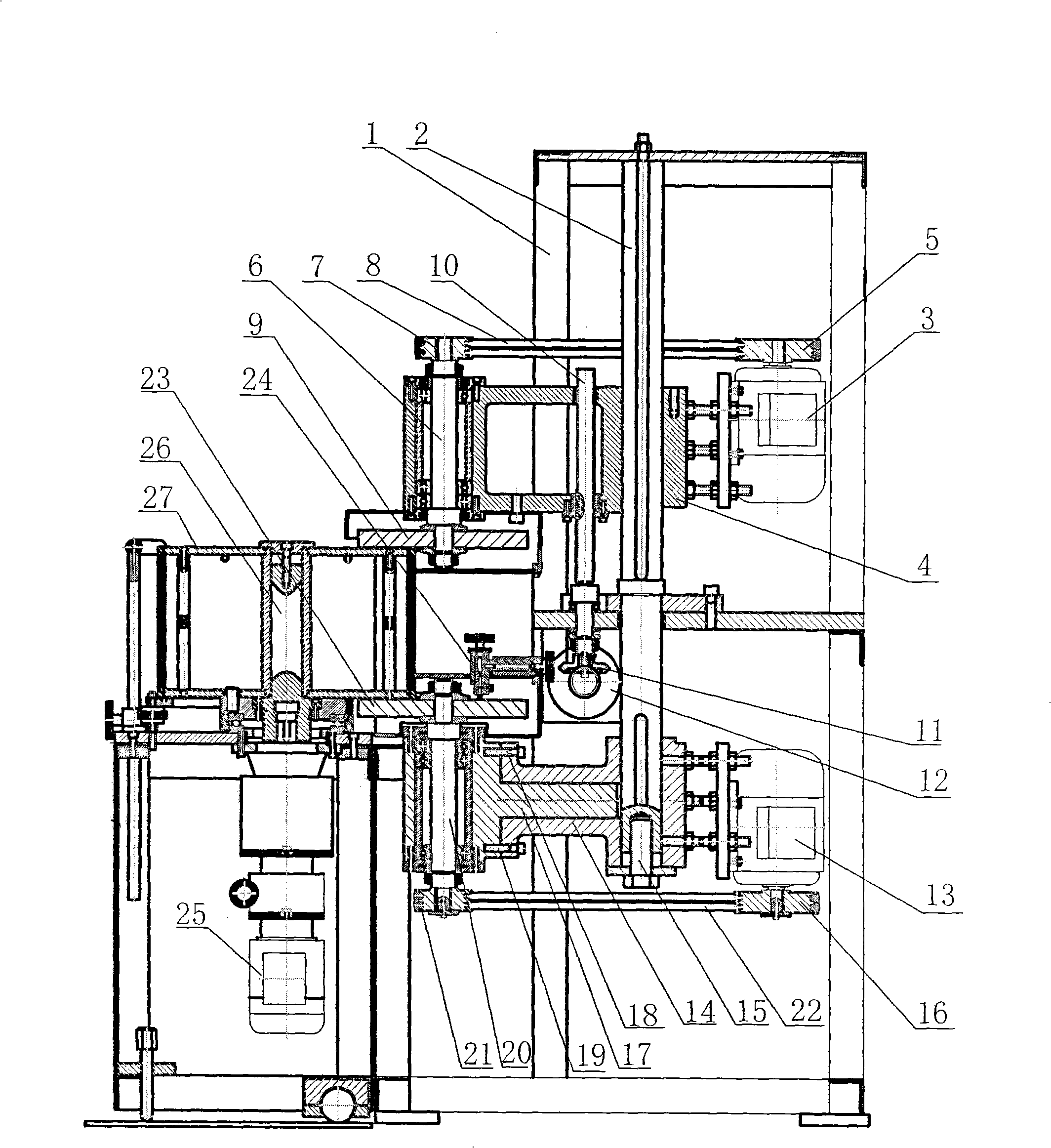

[0014] Such as figure 1 As shown, the guide bar 2 is vertically fixed on the frame 1, and the upper grinding head assembly and the lower grinding head assembly are respectively connected on the guide bar 2.

[0015] The upper grinding head assembly includes a high-speed motor 3 and a slider 4. The slider 4 is sleeved outside the guide rod 2. The high-speed motor 3 is connected to the right side of the slider 4. The output shaft of the high-speed motor 3 is vertically arranged. The high-speed motor 3 The output shaft is connected to the output pulley 5. On the left side of the slide block 4, the vertical grinding disc main shaft 6 is connected by a bearing, and the upper end of the upper grinding disc main shaft 6 is concentrically fixedly connected with the input pulley 7, and the transmission belt 8 is connected between the input pulley 7 and the output pulley 5. The lower end of the upper grinding disc main shaft 6 is fixedly connected with the upper grinding disc 9 concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com