Micro hydrocyclone separation and solid removal method and apparatus of MTO quench water and water of water-washing factory

A technology of micro-swirling and quenching water, applied in the field of coal conversion, can solve the problems such as the large increase in the amount of reaction water, the difficulty in removing solid particles from the stripping reaction wastewater, and the decrease in the recycling rate of the quenching wastewater.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

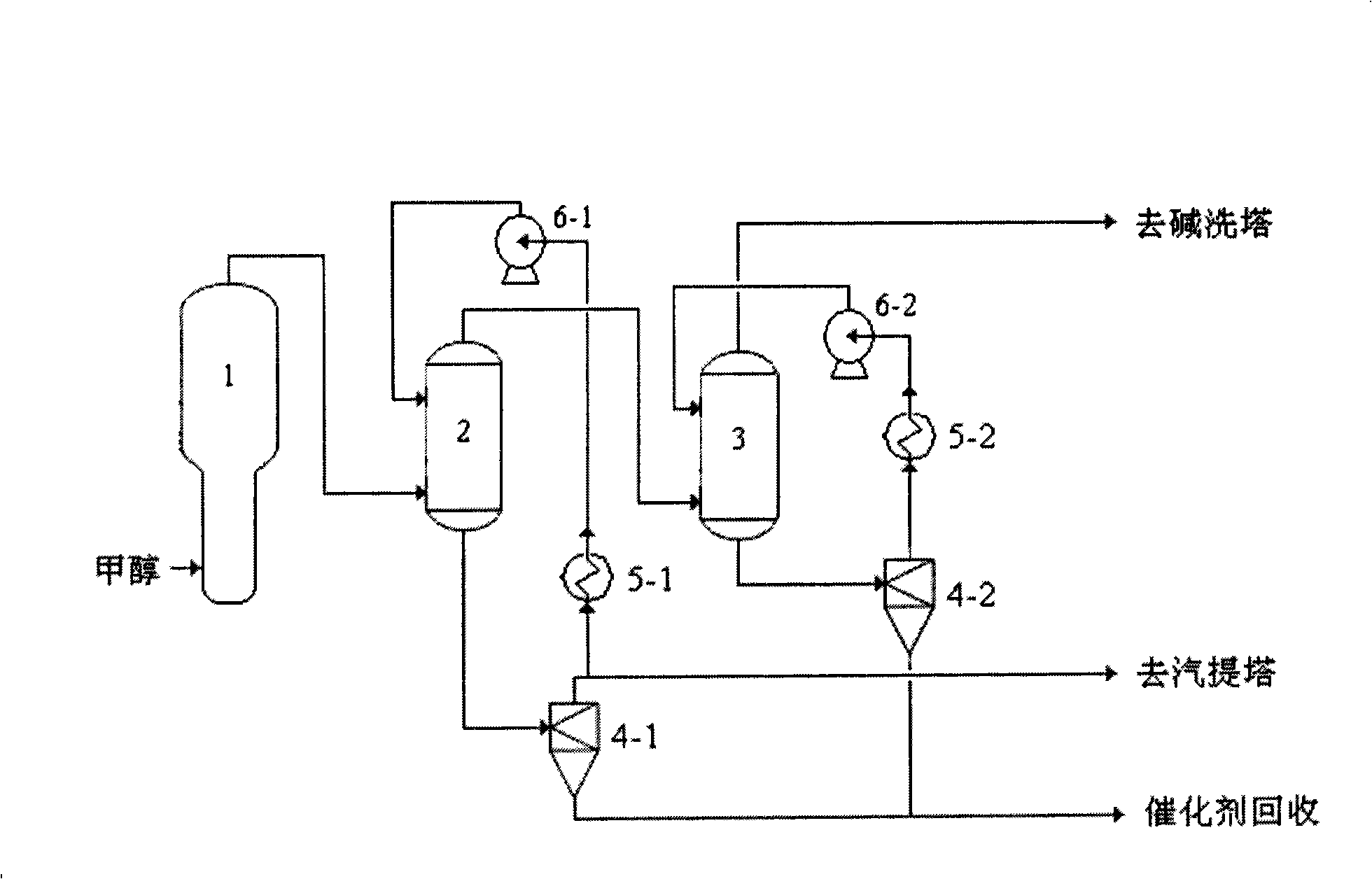

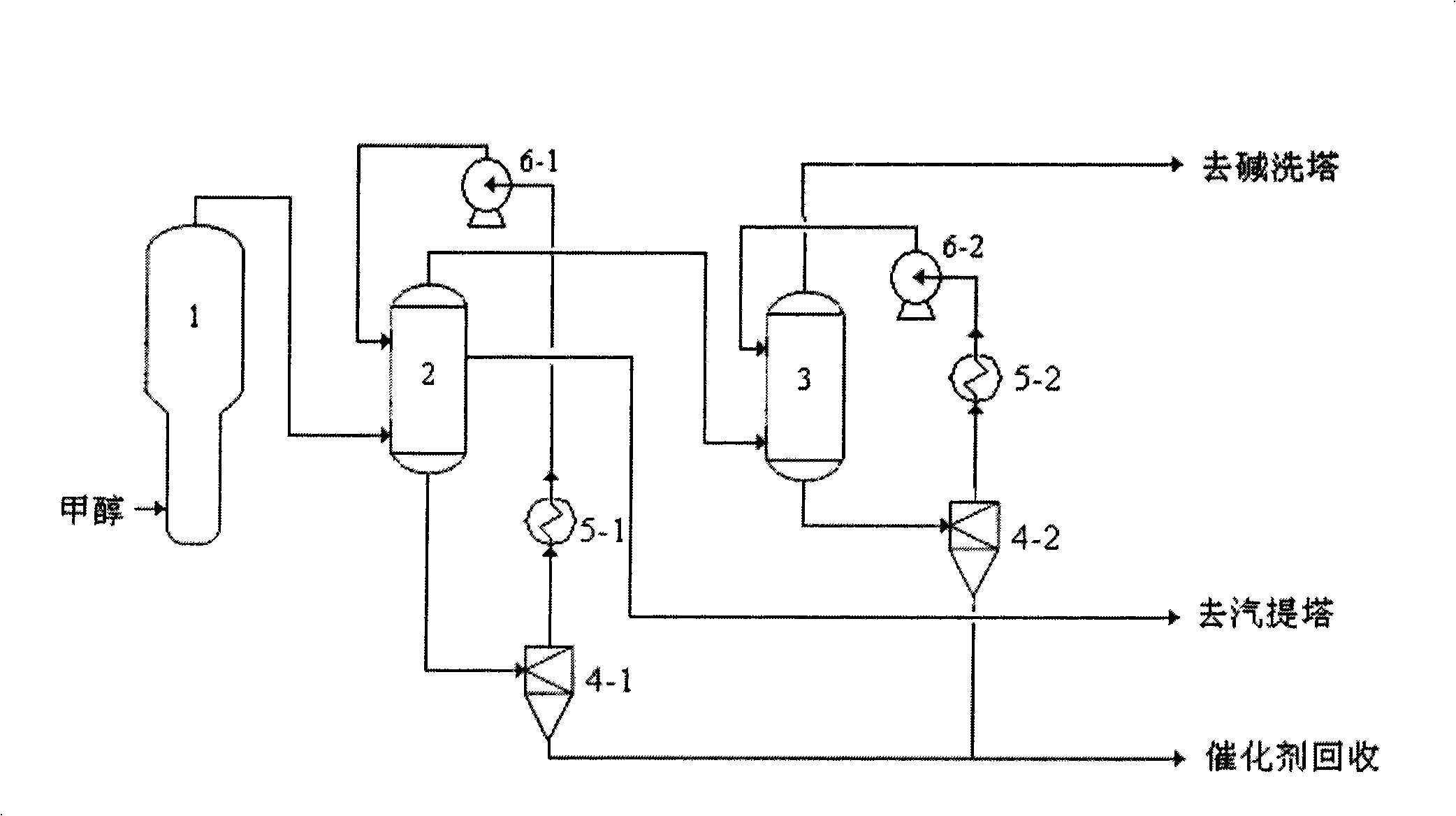

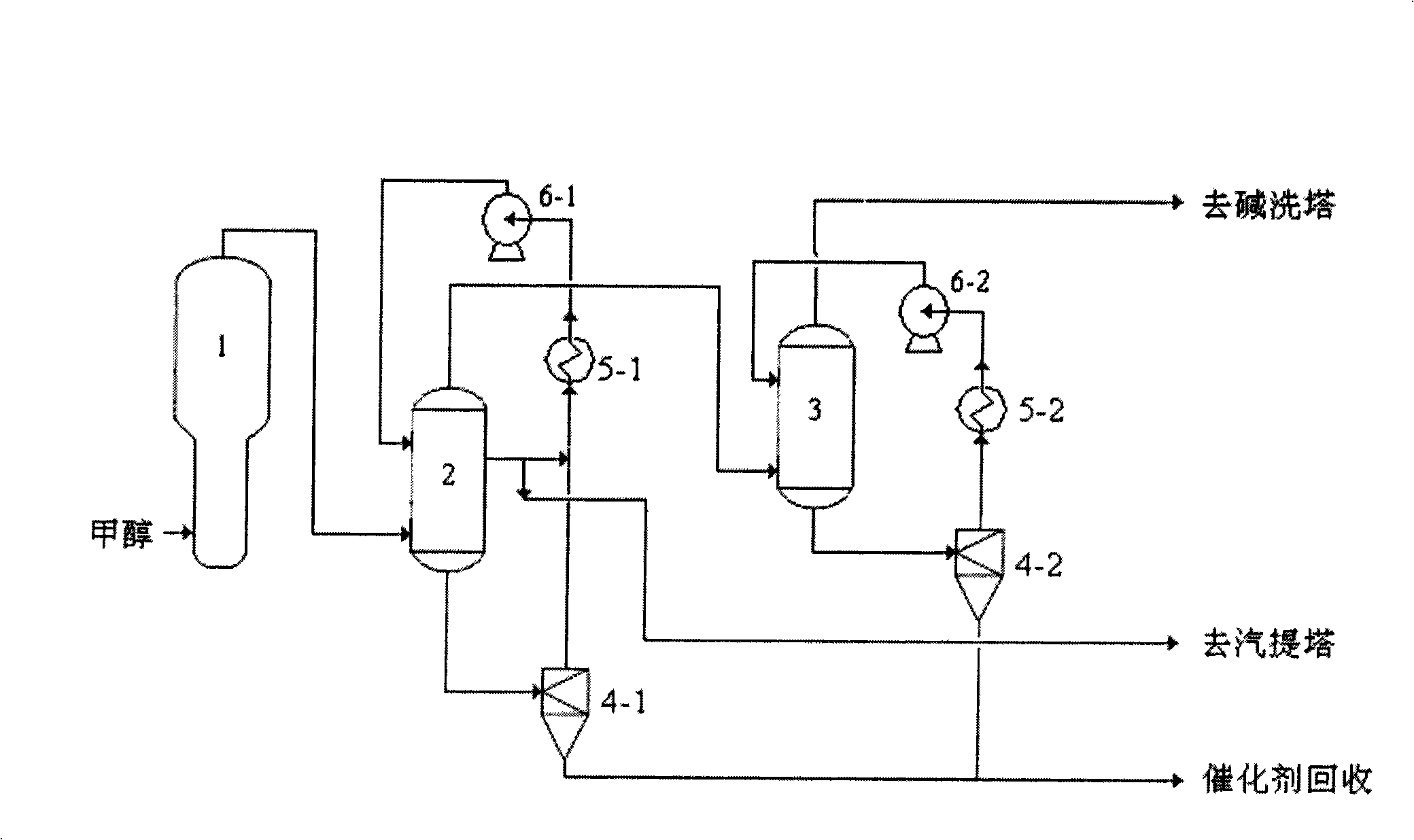

[0027] The inventor of the present invention finds after extensive and in-depth research that the most effective and cheap method is to use a cyclone separator for MTO quenching water and washing water, which have a large operating flux and a low solid-liquid system; However, since the particle size of the conventional cyclone and hydrocyclone separator is greater than 5 microns, it is difficult to remove solid particles below 5 microns under normal working conditions. Catalyst particles in water, because the micro cyclone separator has the advantages of wide applicability, simple structure, strong adaptability, easy maintenance, high reliability, etc., and compared with ordinary cyclone separation devices, the separation efficiency is higher a lot (d 75 less than 3 microns). The present invention has been accomplished based on the above findings.

[0028] MTO is the abbreviation of Methane To Olefin, that is, methanol to olefins. The reaction mechanism of MTO is that metha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com