Method for preparing liquid complex enzyme for feeding

A liquid compound enzyme and filtrate technology, applied in the application, animal feed, animal feed and other directions, can solve problems such as increasing the cost of feed enzymes, and achieve the effects of protection effectiveness, feed quality improvement and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

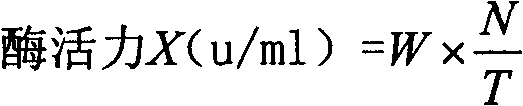

Embodiment 1

[0024] First, the solid fermented koji is broken, and the koji block is crushed to below 5mm particle size with a crusher, and water is added to the koji according to the weight ratio of koji: water=1:1, and the koji is stirred and moistened; then the wet koji Squeeze with a press to obtain filtrate and slag, and the slag can be used as solid feed enzyme after drying. Add its 5% weight diatomite filter aid in the squeezed filtrate, obtain the filtrate after filtering with a plate-and-frame filter; Glycerin stabilizer and potassium sorbate preservative are added into the liquid, and the liquid compound enzyme for feeding can be obtained by stirring evenly. Its enzyme components include xylanase, pectinase, mannanase, β-glucanase, cellulase, protease and other components. After determination, the activities of several enzyme components in this example are: xylanase 200000U / ml, pectinase 20000U / ml, mannanase 1000U / ml, β-glucanase 150000U / ml, fiber Sulfase 3000U / ml, protease 100...

Embodiment 2

[0026] The process is the same as in Example 1, 313kg of solid fermented koji material is crushed, and 313kg of water is added to stir. After squeezing, 315kg of filtrate and 308kg of slag are obtained; 311kg of filtrate is obtained by filtration, and 78kg of protective agent is added to obtain 389kg of liquid compound enzyme for feed. Among them, xylanase 241167u / ml, pectinase 80645u / ml.

Embodiment 3

[0028] The process is the same as in Example 1, 625kg of solid fermented koji material is crushed, and 625kg of water is added to stir. After squeezing, 630kg of filtrate and 617kg of slag are obtained; 626kg of filtrate is obtained by filtration, and 157kg of protective agent is added to obtain 783kg of liquid compound enzyme for feed. Among them, xylanase 255633u / ml pectinase 81632u / ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com