Mechanism for locating and guillotining terminal

A terminal and cutting technology, which is applied in the field of terminal positioning and cutting mechanism, can solve the problems of complex mechanism, low production efficiency, waste of working hours, etc., and achieve the effect of simplifying the mechanism and saving working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

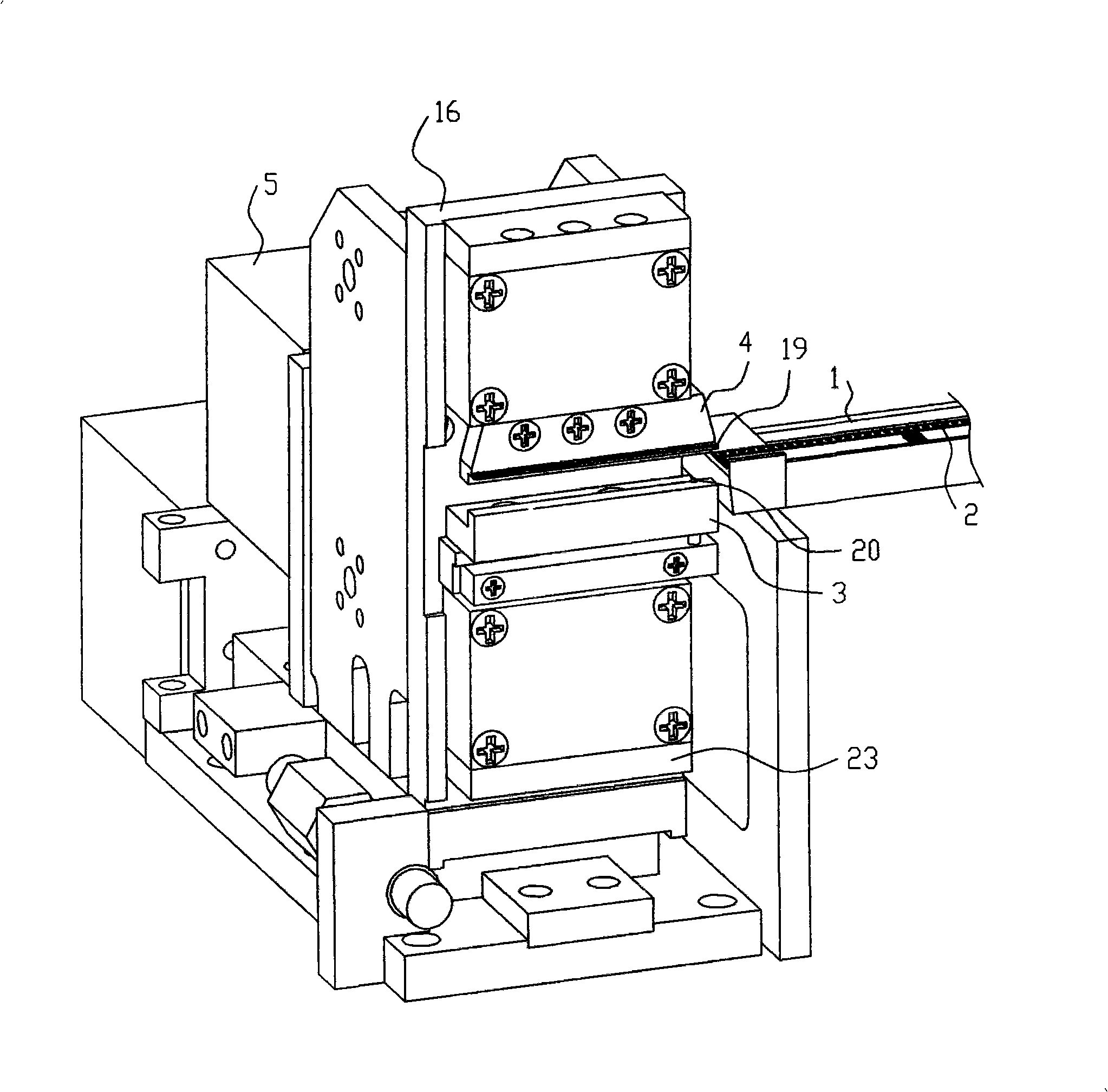

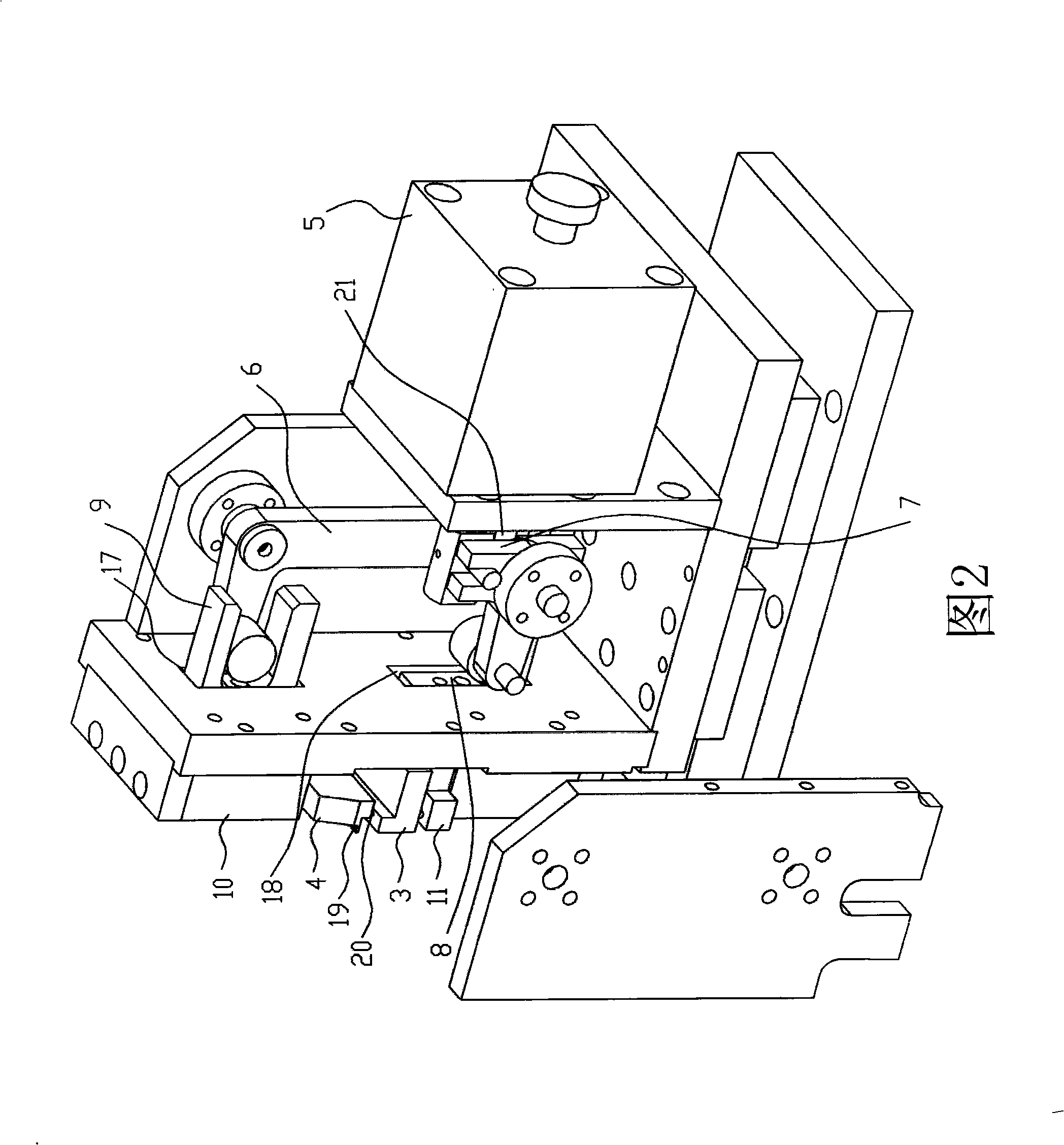

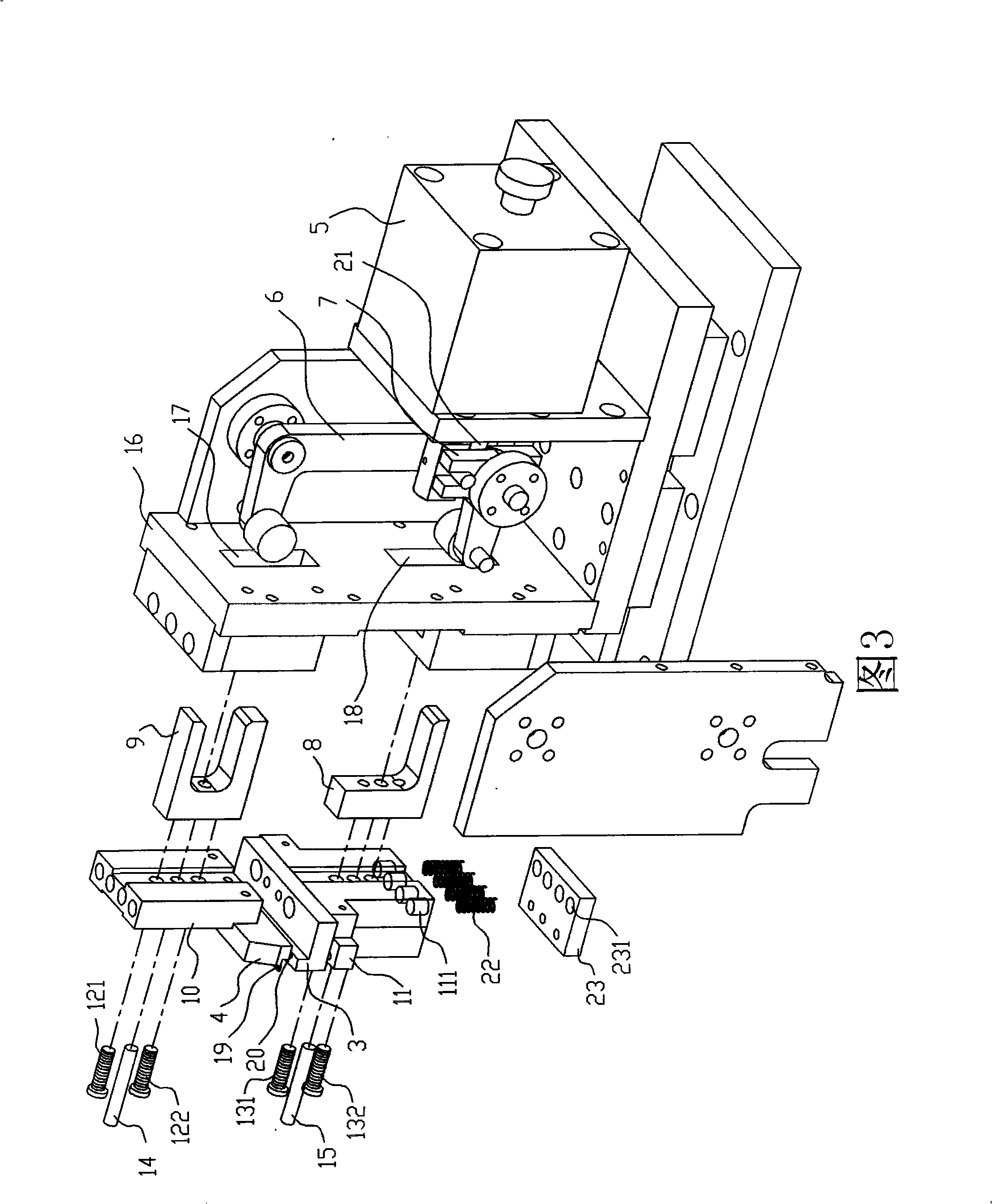

[0021] Please refer to figure 1 , Figure 2, and Figure 3, which are respectively shown as a three-dimensional structure diagram of a preferred embodiment of the terminal positioning and cutting mechanism of the present invention before cutting, and a side three-dimensional structure of a preferred embodiment of the terminal positioning and cutting mechanism of the present invention Fig. 1 is an exploded view of the side three-dimensional structure of a preferred embodiment of the terminal positioning and cutting mechanism of the present invention.

[0022] The terminal positioning and cutting mechanism of the present invention is applied to terminal positioning and cutting. In this embodiment, the structure includes:

[0023] A body 16, on which a first opening 17 is arranged near the top end, and a first slider 9 is movably arranged in the first opening 17, the first slider 9 is "C" shaped, and the body 16 is near the bottom A second opening 18 is provided at the position, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com