Method for purifying sea-mussel mucin by carboxymethyl ion exchange chromatography

An ion exchange chromatography and mussel mucin technology, which is applied in the field of protein purification, can solve problems such as low yield of mussel mucin, and achieve the effects of high selectivity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

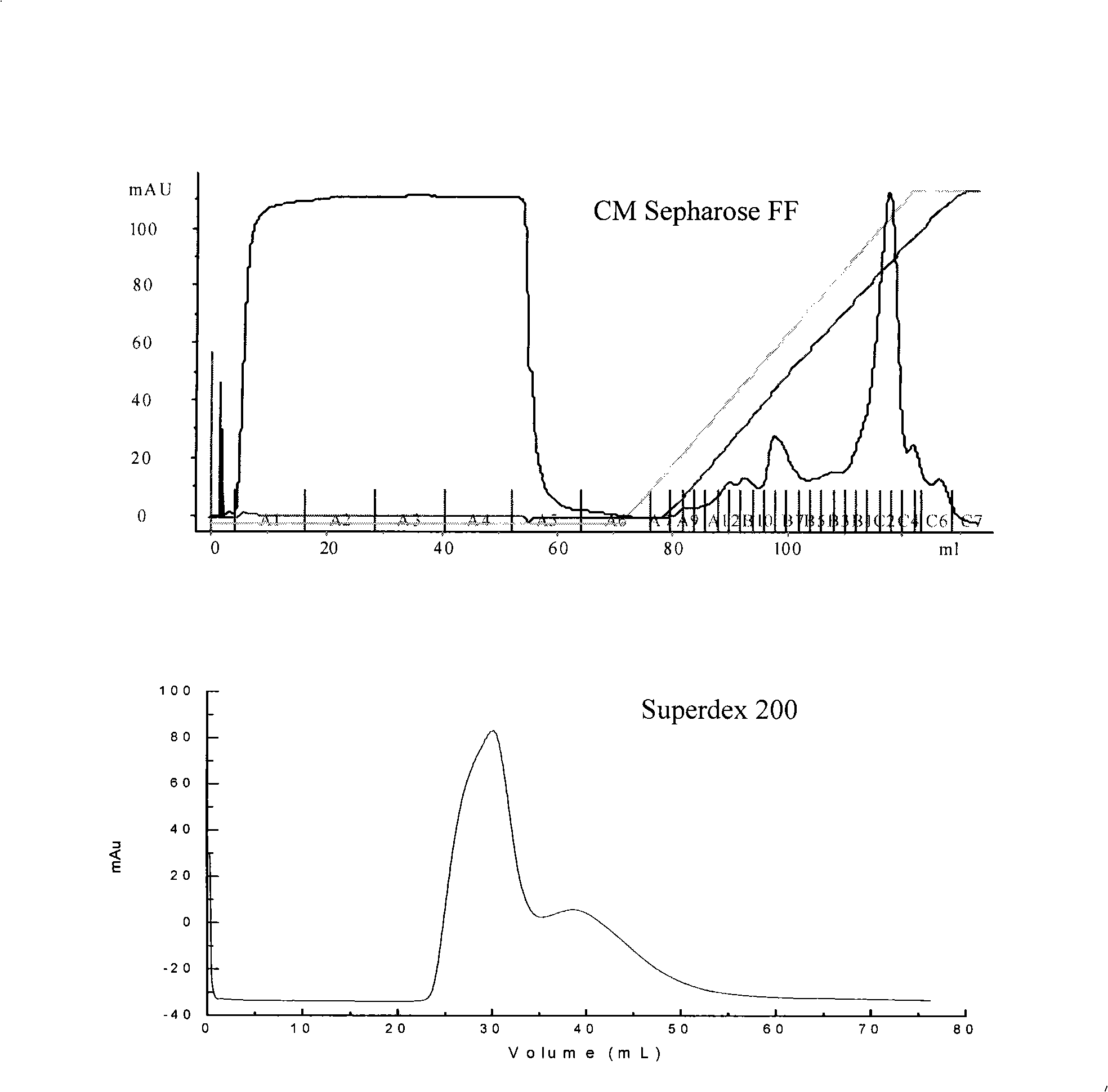

[0027] Example 1. Using CM Sepharose FF medium in combination with Superdex 200 medium to separate and purify mussel mucin

[0028] 1) Using 0.5% perchloric acid and 2% acetic acid as the extraction solvent, add 100g mussel foot silk to 400ml extraction solvent, extract at 18°C for 12min, use a stirrer to crush the frozen mussel foot silk at high speed and suspend it evenly in in the extraction solvent;

[0029] 2) centrifuge at 12000r / min for 35min, and keep the supernatant;

[0030] 3) Sephadex G-25 was used to remove small molecular compounds, the mobile phase was 20mM sodium acetate buffer solution with pH 2.5, 0.15M sodium chloride was added, and the breakthrough peak was collected;

[0031] 4) Concentrate fractions with Millipore CENTRIPLUS ultrafiltration membrane;

[0032] 5) CM Sepharose FF ion exchange medium is used, the mobile phase is pH4, and the adsorption mobile phase is 0.1M sodium chloride, and the elution is performed by a linear gradient of 0.5-1.2M sod...

Embodiment 2

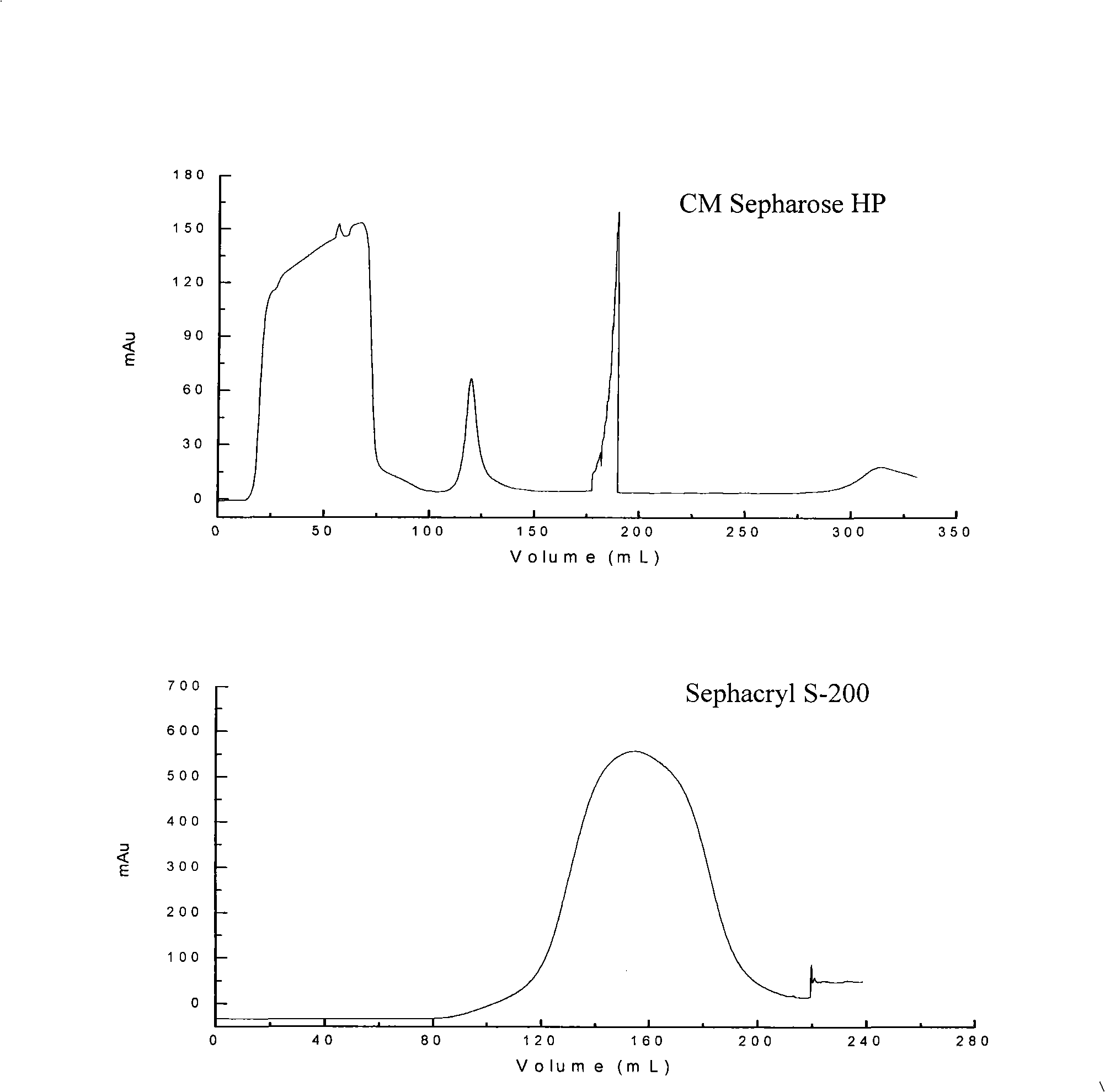

[0040] Example 2. Using CM Sepharose HP in combination with Sephacryl S-200 medium to separate and purify mussel mucin

[0041] 1) Using 1% perchloric acid as the extraction solvent, add 100 g of mussel foot silk to 300 ml of extraction solvent, extract at 15°C for 15 minutes, use a stirrer to crush the frozen mussel foot silk at high speed and suspend it in the extraction solvent;

[0042] 2) Remove the residue by filtering with a 45 μm filter membrane, and keep the supernatant;

[0043] 3) Sephadex G-50 was used to remove small molecular compounds, the mobile phase was 30mM sodium acetate buffer solution with pH 3.0, 0.2M sodium chloride was added, and the breakthrough peak was collected;

[0044] 4) Concentrate fractions with Millipore CENTRIPLUS ultrafiltration membrane;

[0045] 5) Using CM Sepharose HP ion exchange medium, mobile phase pH 5, adsorption mobile phase is 0.3M sodium chloride, elution is 0.5-1.2M sodium chloride linear gradient elution within 10-20 column v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com