Improved process of activated sludge and biological film composite type A2/O

A technology of activated sludge and biofilm, applied in the field of urban sewage treatment, achieves the effects of low cost, strong adaptability and stability, and improved nitrification reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

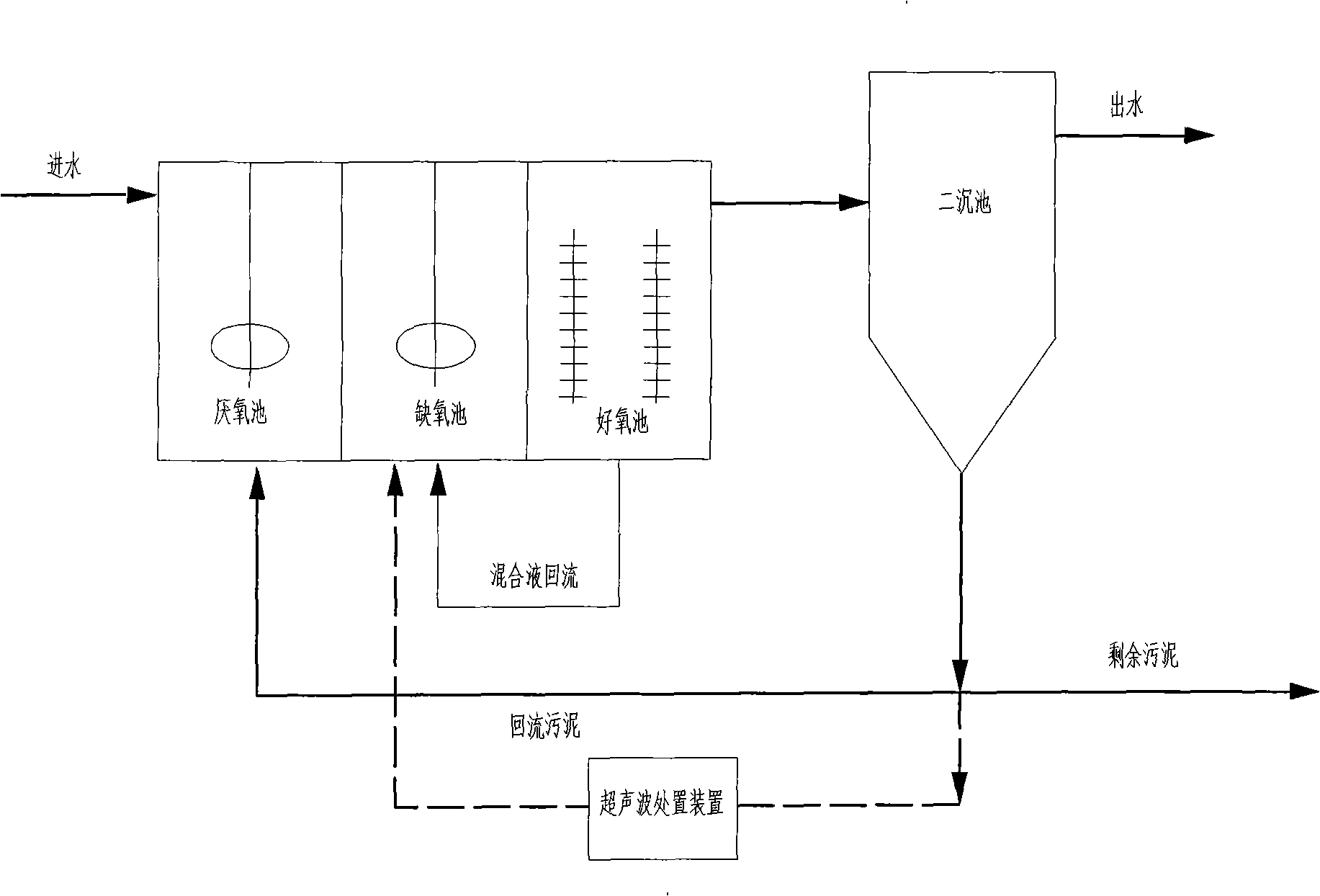

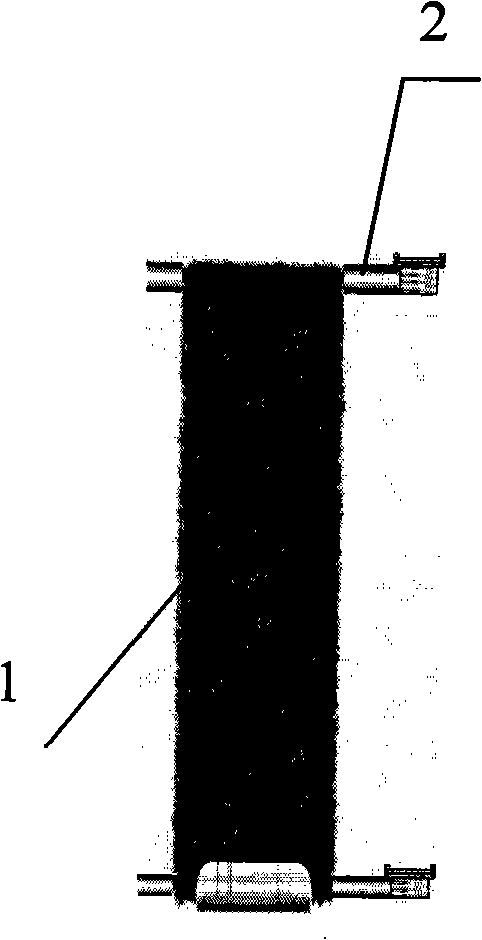

[0018] figure 1 It is a process flow diagram of the present invention, which consists of three stages of anaerobic, anoxic and aerobic processes. This is a common A2 / O process. This improved A2 / O process is to add ciliated biological filler in the aerobic reactor 1. Use an ultrasonic treatment device to cavitate and decompose the remaining sludge in the secondary settling tank into liquid soluble organic matter, and return this part of the sludge to the front end of the anoxic reactor. To add the ciliated biological filler 1, a support 1 needs to be set in the aerobic reactor, the ciliated biological filler 1 is suspended on the support 2, the ciliated biological filler 1 has a tapestry structure, and the blanket surface 3 is composed of porous collagen , the carpet surface 3 is attached with straight hairy coarse fibers 4 .

[0019] with ordinary A 2 / O process is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com