Narrow slit type coating apparatus with improved support mechanism

A coating device and slit-type technology, which are applied to devices and coatings that apply liquid to the surface, can solve the problem that the relative thermal displacement of the coating die and the supporting mechanism cannot be compensated, the service life of the parts is damaged, and the connection part is not compensated. Large thermal stress and other problems, to achieve the effect of flexible height adjustment, prolonging service life and eliminating thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] best practice

[0029] The slit coating device provided by the invention has an improved support mechanism, which can be used to apply hot melt adhesive liquid to a coil or carrier continuously conveyed by a roller, which includes a slit coating mold, and is used to apply The coating mold is mounted to the supporting mechanism on the coating equipment frame. Preferably, also comprise the glue recovery device that will describe below.

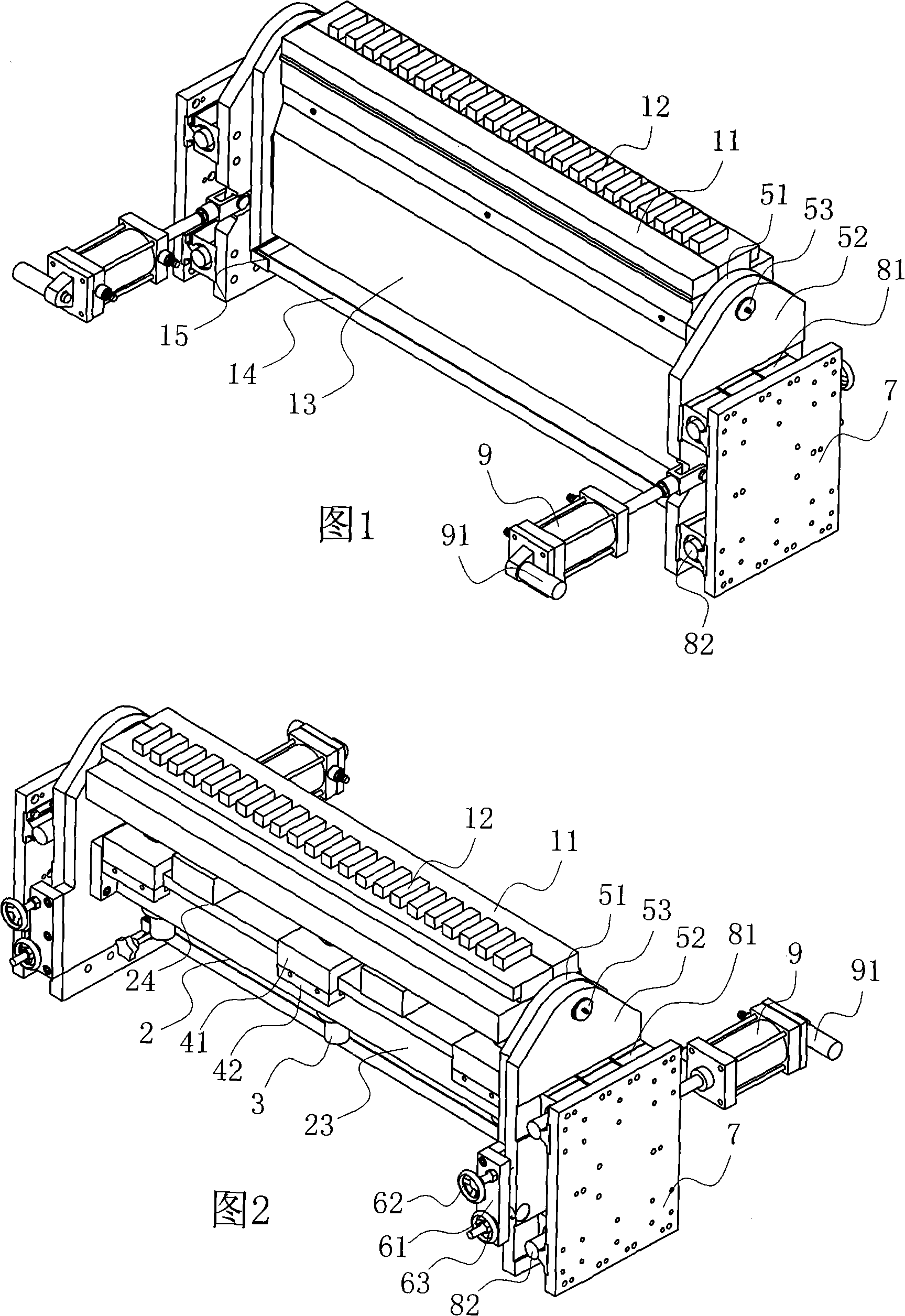

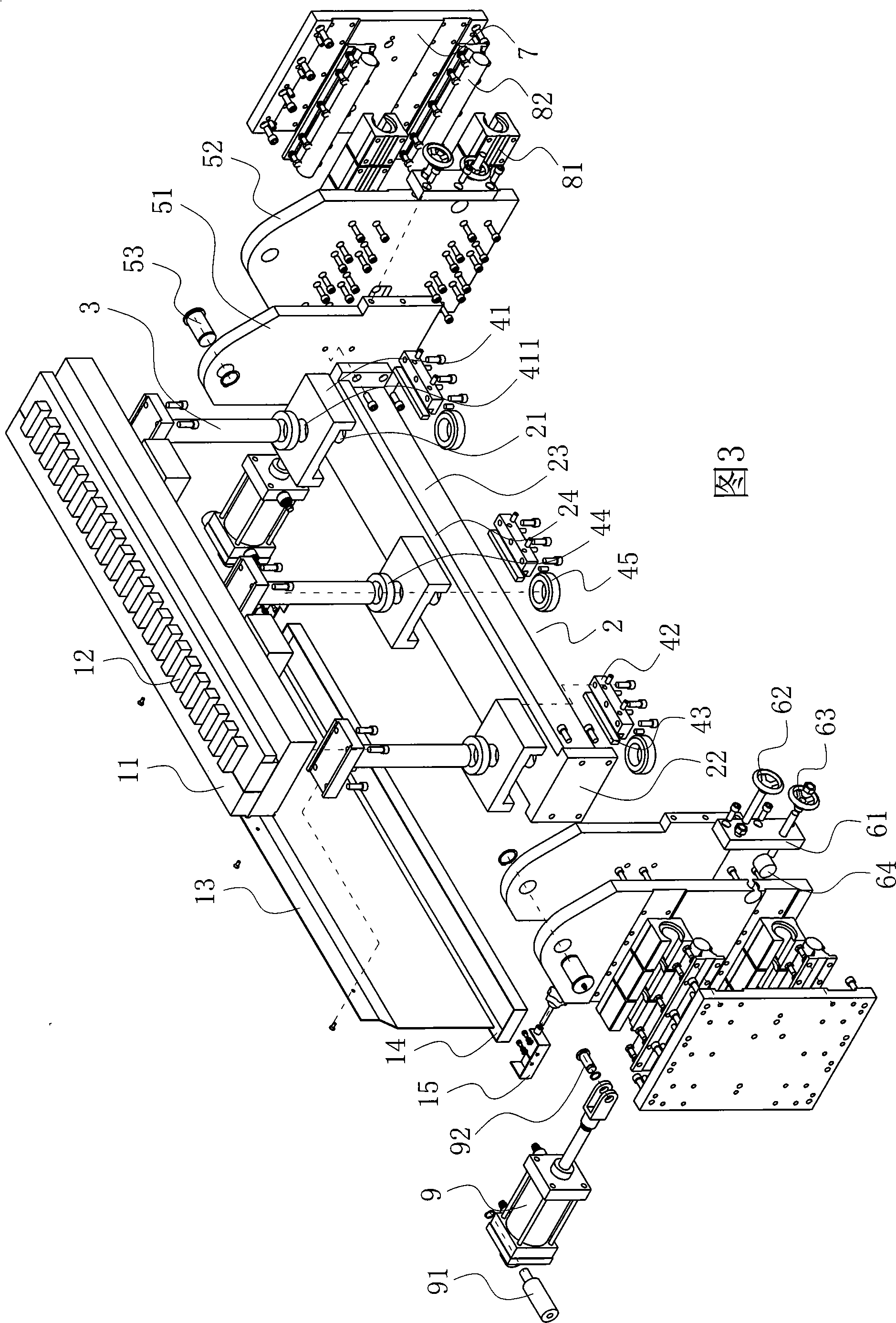

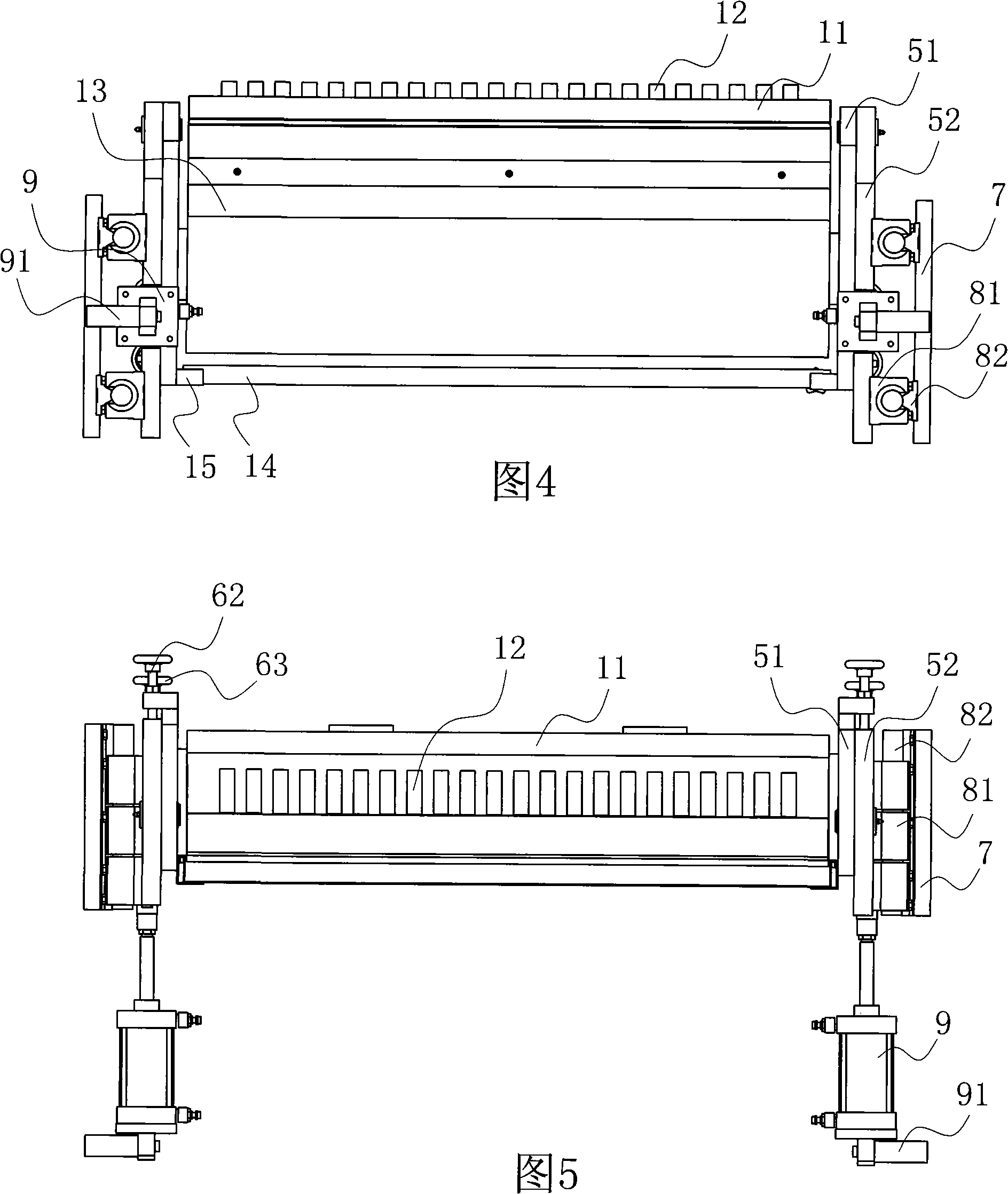

[0030] Refer to Figure 1 to Figure 9 , a slit coating mold with an improved supporting mechanism, comprising a module 11 and a plurality of liquid distributors 12 arranged at intervals along the length direction of the module. The module 11 is formed with a slit extending along the length direction and opening at the front surface of the module and a liquid delivery channel. After the coating mold is installed, the length direction of the module 11 extends parallel to the axis of the roll of the coating equipment, and the slit faces t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com