Lifting mechanism for reclaiming trolley

A technology of lifting mechanism and trolley, which is applied in the field of trolley lifting mechanism for reclaiming materials, can solve the problems of non-stepless adjustment, inconvenient adjustment of trolley height, inconvenient use, etc., and achieves the effects of low manufacturing cost, simple installation and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

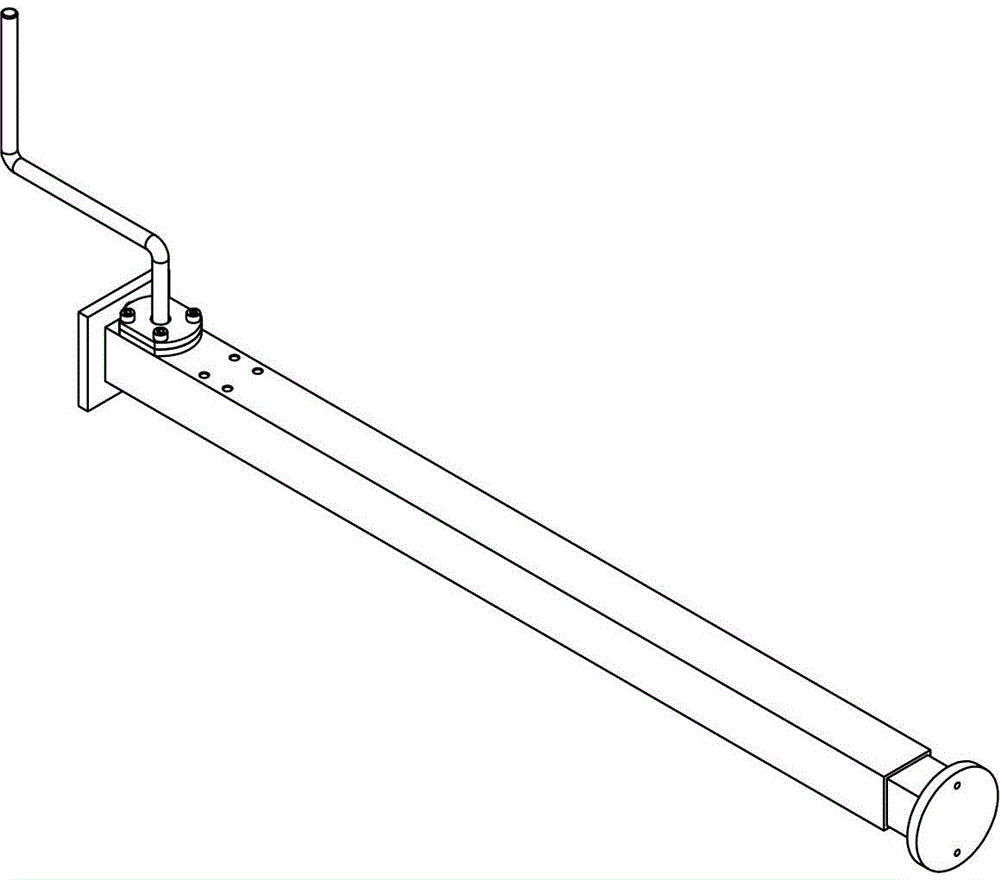

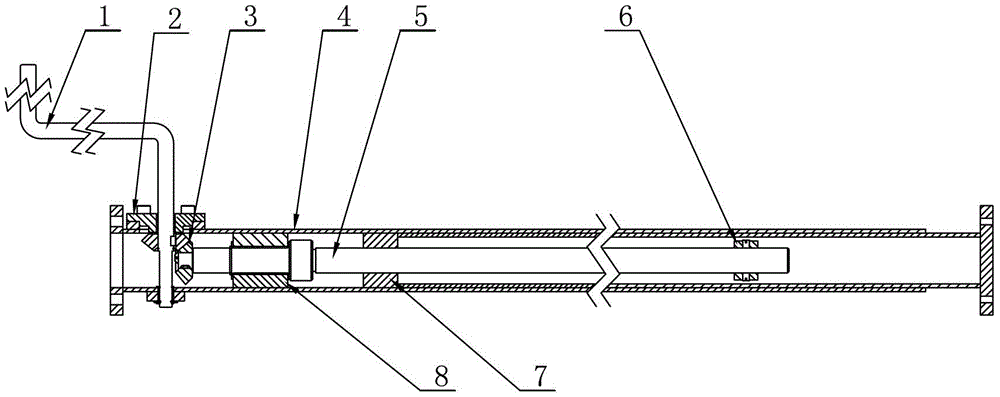

[0009] see Figure 1-Figure 2 , the specific embodiment adopts the following technical scheme: it includes a handle 1, a flange 2, a bevel gear 3, a base 4, a transmission screw 5, a limit block 6, a lifting platform 7, a support block 8, and the flange 2 is installed on the base 4 One end of the handle 1 passes through the flange 2 and is installed on the base 4 through the flanging bushing and the circlip for the shaft. The support block 8 is set inside the base 4, and one side of the transmission screw 5 is connected to the support block. 8, two bevel gears 3 are respectively installed on the handle 1 and one end of the transmission screw 5 through a flat key, and the two bevel gears 3 are matched, the limit block 6 is installed on the other side of the transmission screw 5, and the lifting platform 7 Socketed on the drive screw 5.

[0010] This specific implementation is mainly used in the casting processing process with a high degree of automation in the foundry industry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com