Solid-liquid separator for slime water

A solid-liquid separator, slime water technology, applied in the direction of filtration separation, separation method, mobile filter element filter, etc., can solve the problems of waste of land resources, long processing time, large area of sedimentation tank, etc., to achieve land occupation The effect of small area and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

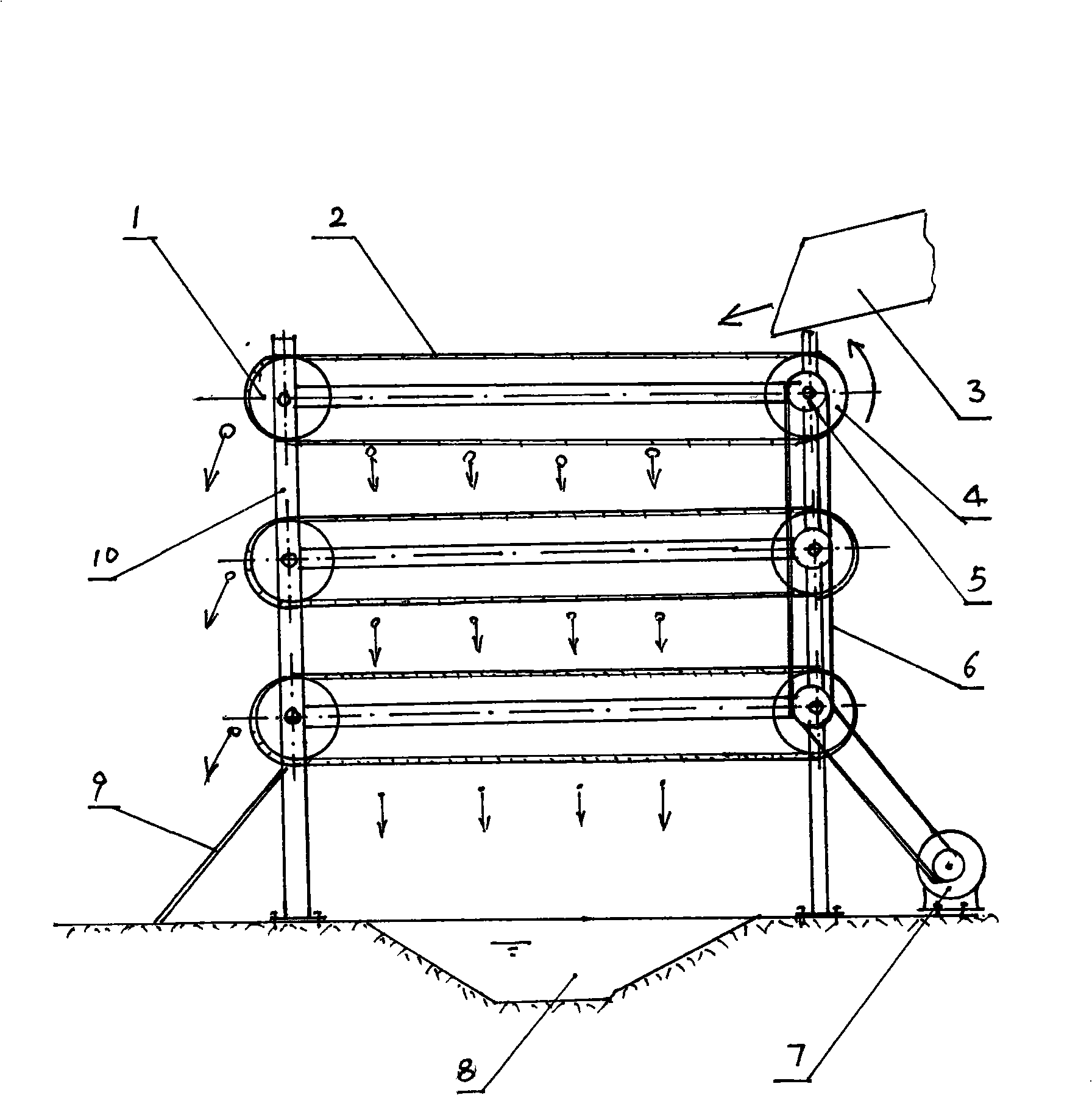

[0010] like figure 1 As shown, the structure of the present application is: including a frame 10, the frame 10 is arranged with driving rollers 4 and corresponding passive rollers 1 in layers, and each layer of the driving rollers 4 and the passive rollers 1 is wound with a butted filter screen 2 , the mesh number of the filter screen 2 decreases sequentially from the top layer to the bottom layer, and the driving roller 4 is dragged by the speed regulating motor 7 . A pulley 5 is installed on the driving roller 4, and the transmission with the speed regulating motor 7 is realized through the V-belt 6.

[0011] In addition, a coal baffle 9 is provided on the front and lower side of the passive roller 1 side to prevent solid-liquid mixing.

[0012] In use, the coal water pipe 3 is arranged above the driving roller 4, and the filtered coal slime water flows through the filter screen 2 to the water collecting tank 8 arranged under the frame 10, and finally flows away in a concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com