AMT shift endurance quality testing bench

A test-bed, durability technology, applied in vehicle testing, machine/structural component testing, machine gear/transmission testing, etc., can solve the problems of insufficient flexibility, single function, high cost, and achieve high linear speed Low noise, noise isolation and vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

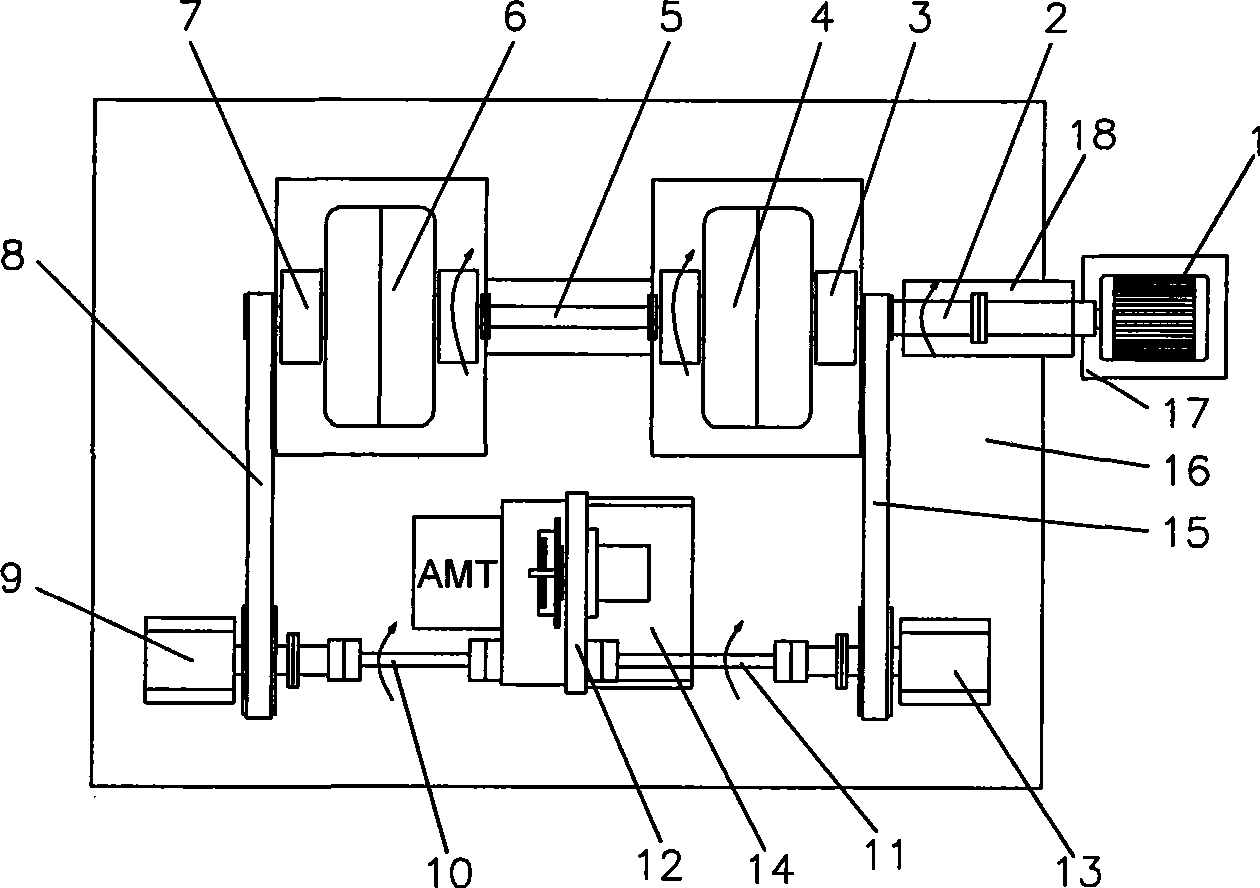

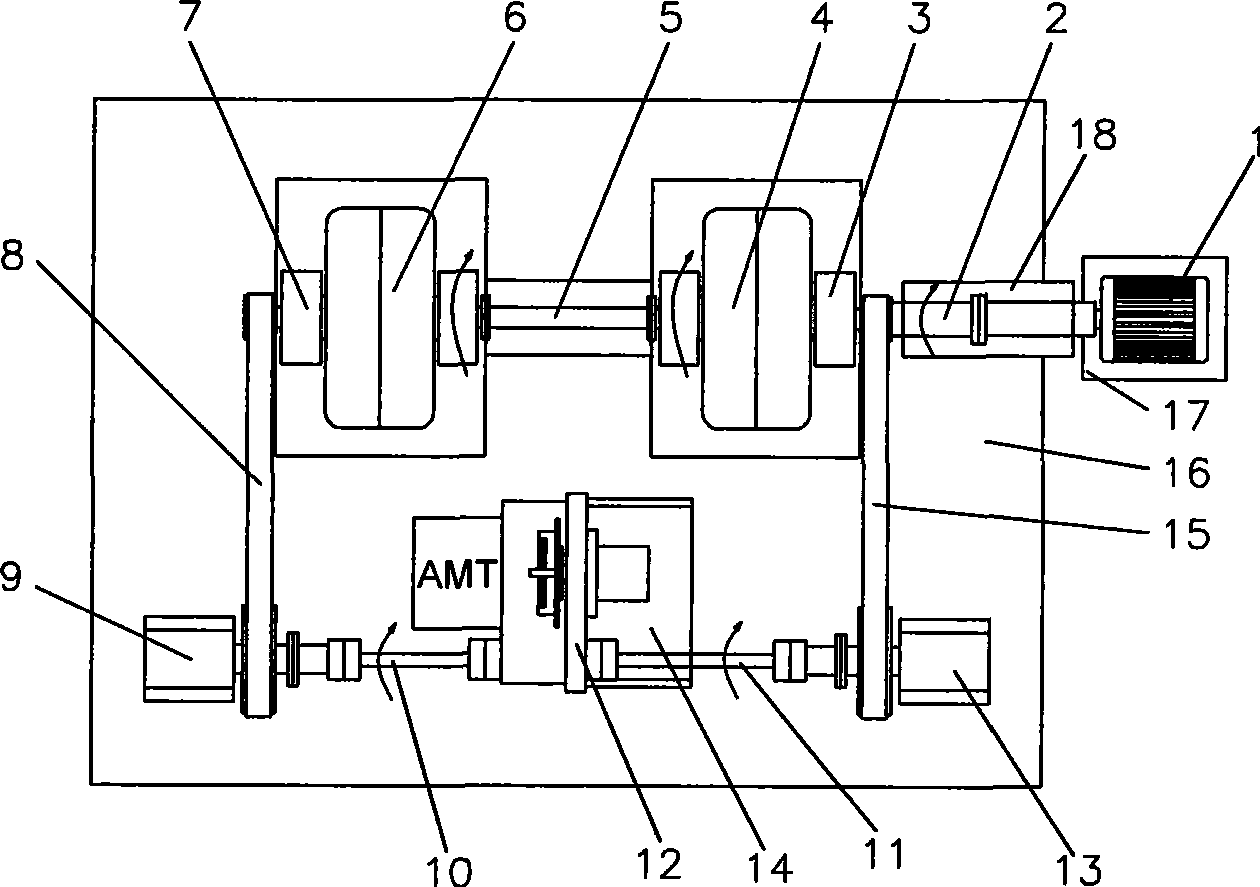

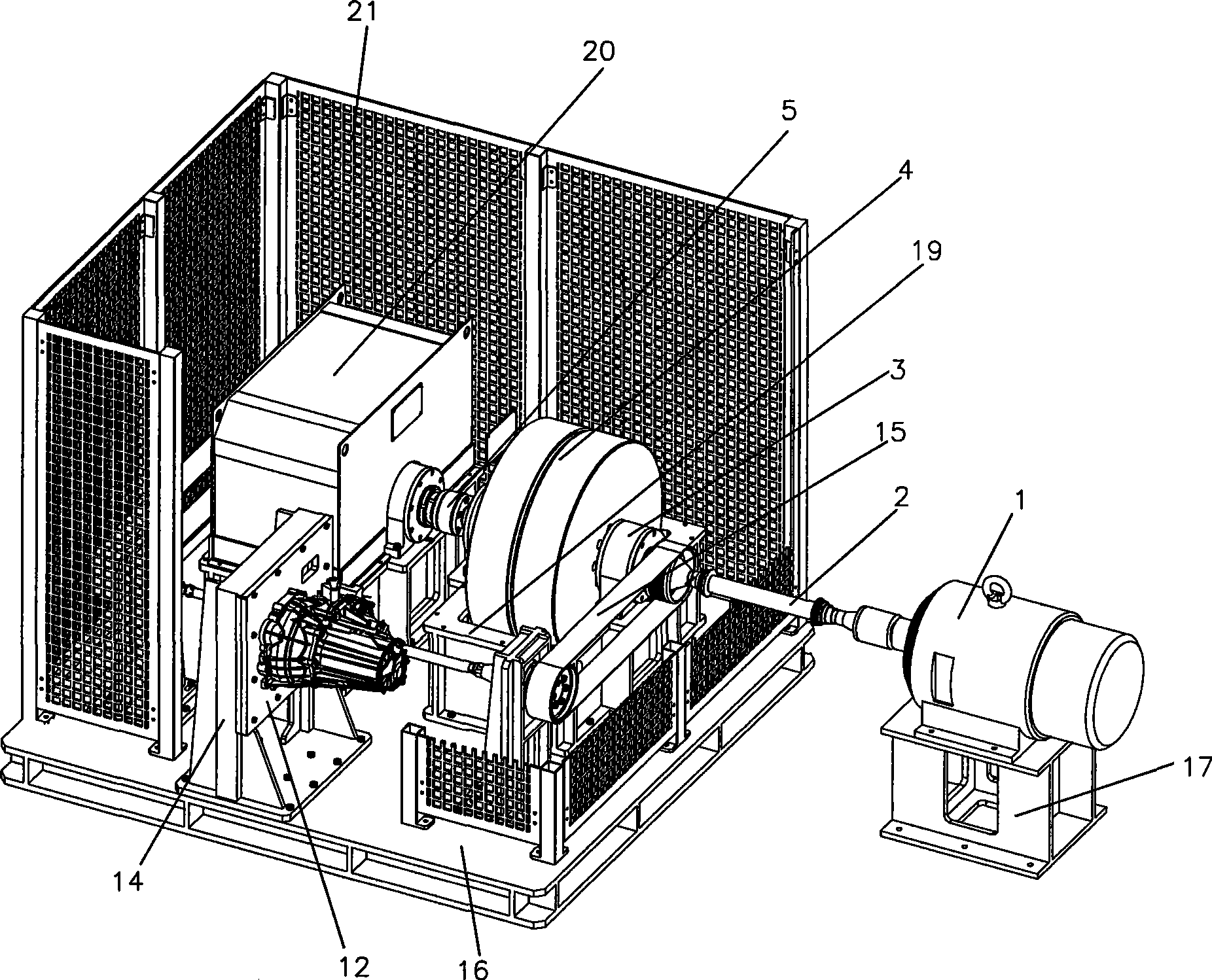

[0025] Referring to Fig. 1 and Fig. 2, on the base 16 of the test bench, the connection of the left flywheel 6 and the right flywheel 4 through the elastic coupling 5 constitutes a unitized synchronously rotating double-inertia flywheel set, and the left half shaft 10 of the transmission and the right side of the transmission Between the half shaft 11 and the left and right shaft ends of the double inertia flywheel group, the left drive belt 8 and the left driven pulley 9, as well as the right drive belt 15 and the right driven pulley 13 constitute the power transmission mechanism, and the double inertia flywheel The power source is provided by the variable frequency motor 1; the transmission AMT is fixedly set on the corresponding type of transmission fixture plate 12, and the input shaft and output shaft during the shifting process of the transmission are simulated by the left half shaft 10 and the right half shaft 11 of the transmission.

[0026] As shown in Figure 1, the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com