Method for removing forerunner of atom layer deposition process

An atomic layer deposition and precursor technology, applied in metal material coating process, coating, gaseous chemical plating, etc., can solve the problem that the deposition rate of ALD process cannot be significantly improved, and achieve the removal of precursors and their by-products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

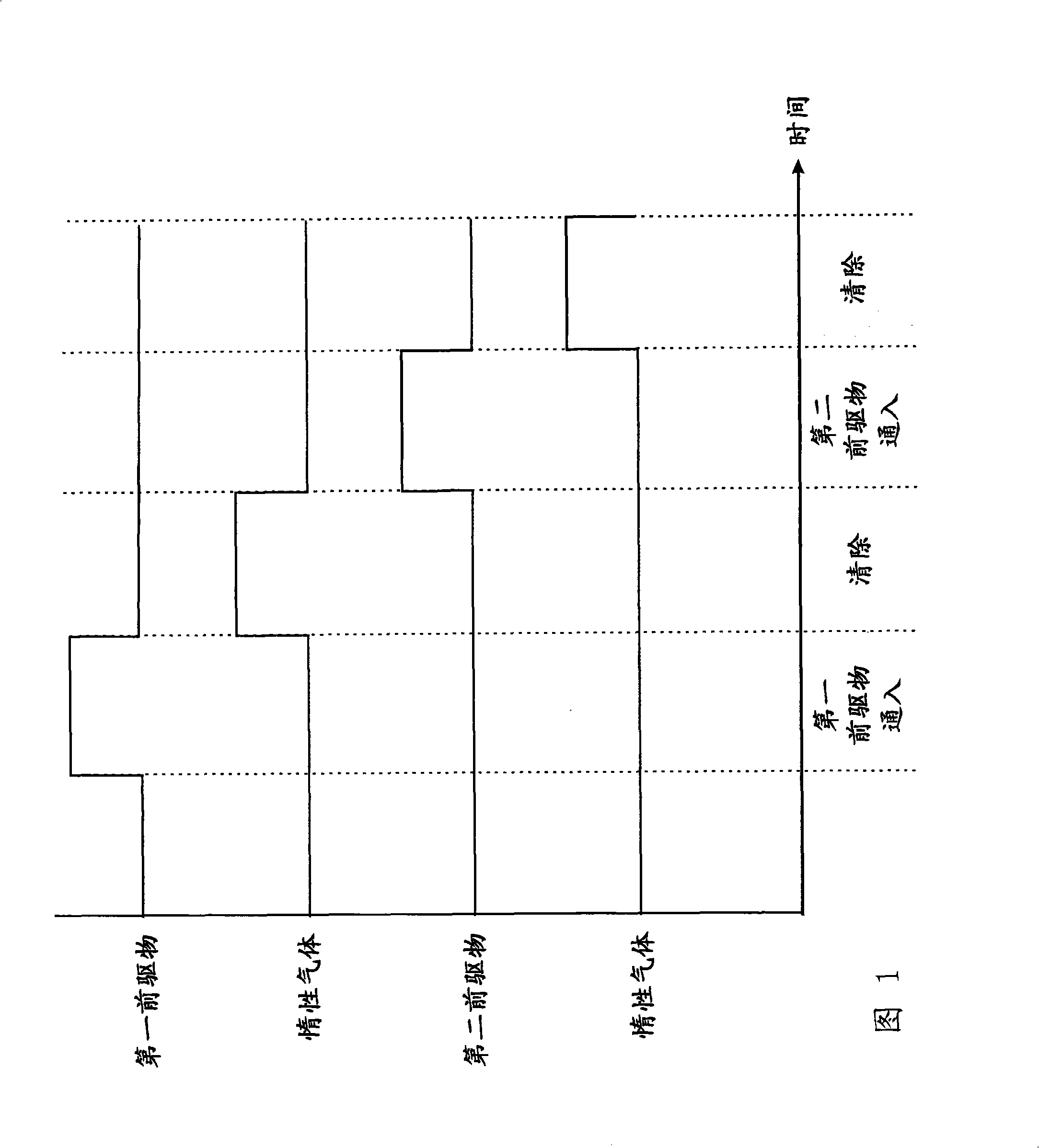

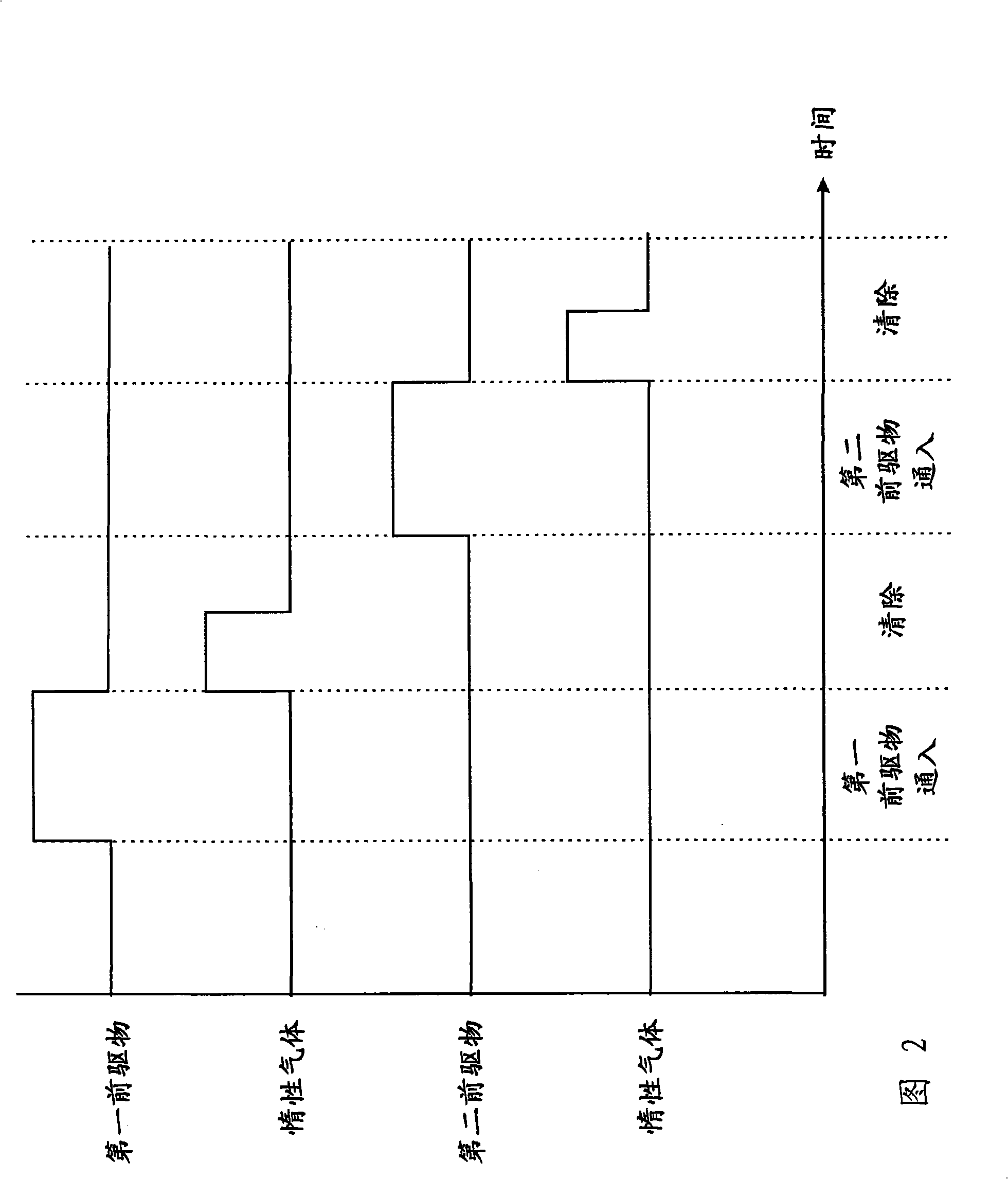

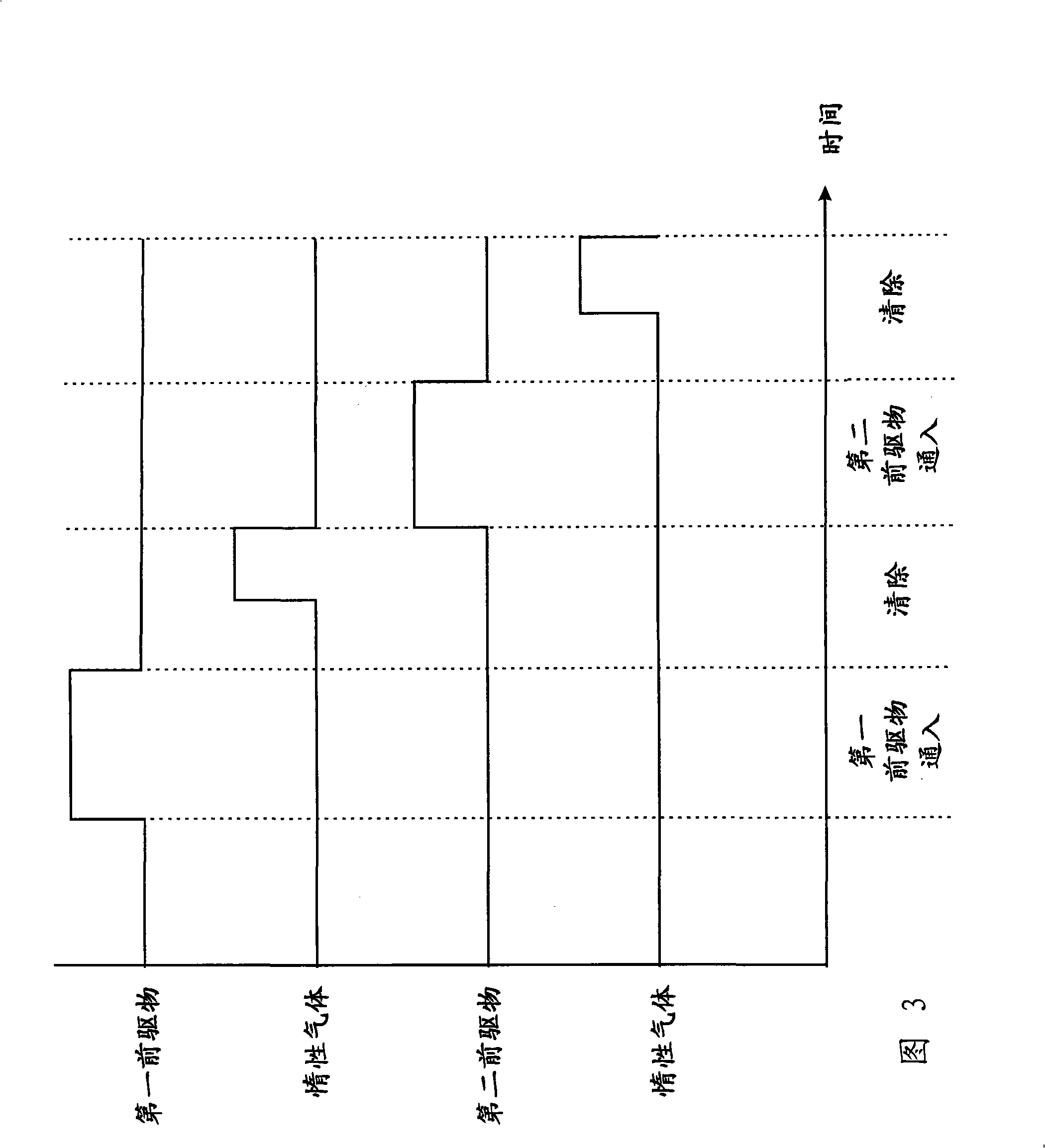

[0020] According to the precursor removal method according to the embodiment of the present invention, during the period when the precursor removal step is to be performed in the atomic layer deposition process, the inert gas (such as argon) is introduced and the inert gas is stopped at least once. The period of the precursor removal step refers to the period from the end of each precursor deposition step to the beginning of the passage of the next precursor during the atomic layer deposition process.

[0021] According to an embodiment of the present invention, an inert gas can be introduced once during the precursor removal step, and the residual precursor and its by-products can be removed with pumping, and the inert gas can be introduced for less time than the precursor The time of the purge step. There can be one or two gaps in the period of the precursor purge step without inert gas. In this gap, pumping is continued, by intermittently inert gas and stop. Inert gas can effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com