Grinding mill for link lever tooth surface of diesel engine

A diesel engine and grinding machine technology, which is applied in the direction of grinding machines, grinding drive devices, grinding machine tool parts, etc., can solve the problem that the tooth surface of the connecting rod cover and the connecting rod body cannot be guaranteed to fit and contact, and the design requirements of the connecting rod cannot be met. , affecting the work of diesel engines and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

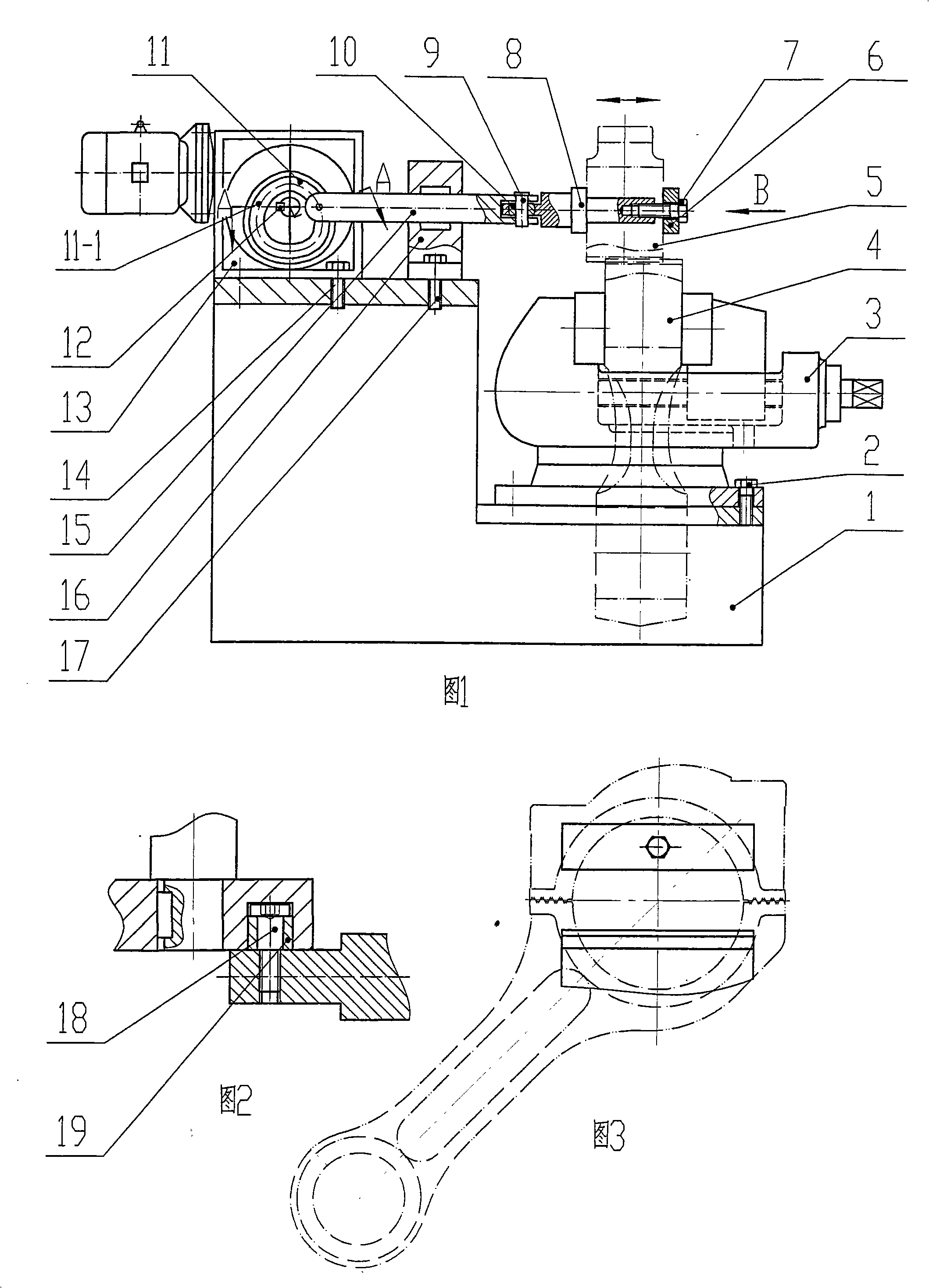

[0008] Below in conjunction with accompanying drawing, the present invention will be further described:

[0009] See Figures 1, 2, and 3, the frequency conversion motor-reducer (13), guide seat (16) and bench vise (3) in the diesel engine connecting rod tooth surface grinding machine are respectively bolted (14), bolt (17), bolt (2) fixed on the frame (1), the cam (11) is connected with the output shaft of the variable frequency motor-reducer (13) through the flat key (12), and the roller moving in the cam groove (11-1) ( 19) is fixed on the moving bar (15) by the screw (18), the moving bar (15) is limited in the hole of the guide seat (16), the joint bearing (10) is housed on the clamping bar (8), and the pin ( 9) It is hinged with the moving rod (15), the connecting rod cover (5) is placed on the connecting rod body (4) clamped by the vise (3), and the connecting rod body (4) is clamped by the clamp (3) The rod cover (5) is connected with the clamping rod (8).

[0010] See...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com