Method for manufacturing guide plate for growing positioning and orientating of dental

A technology of positioning, orientation, and manufacturing methods, which is applied in dentistry, dental prostheses, and dental implants. It can solve the problems of increasing surgical errors, being unable to determine the implantation direction of implantation nails, and reducing the stability of implantation nails, so as to achieve convenient observation. and the effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

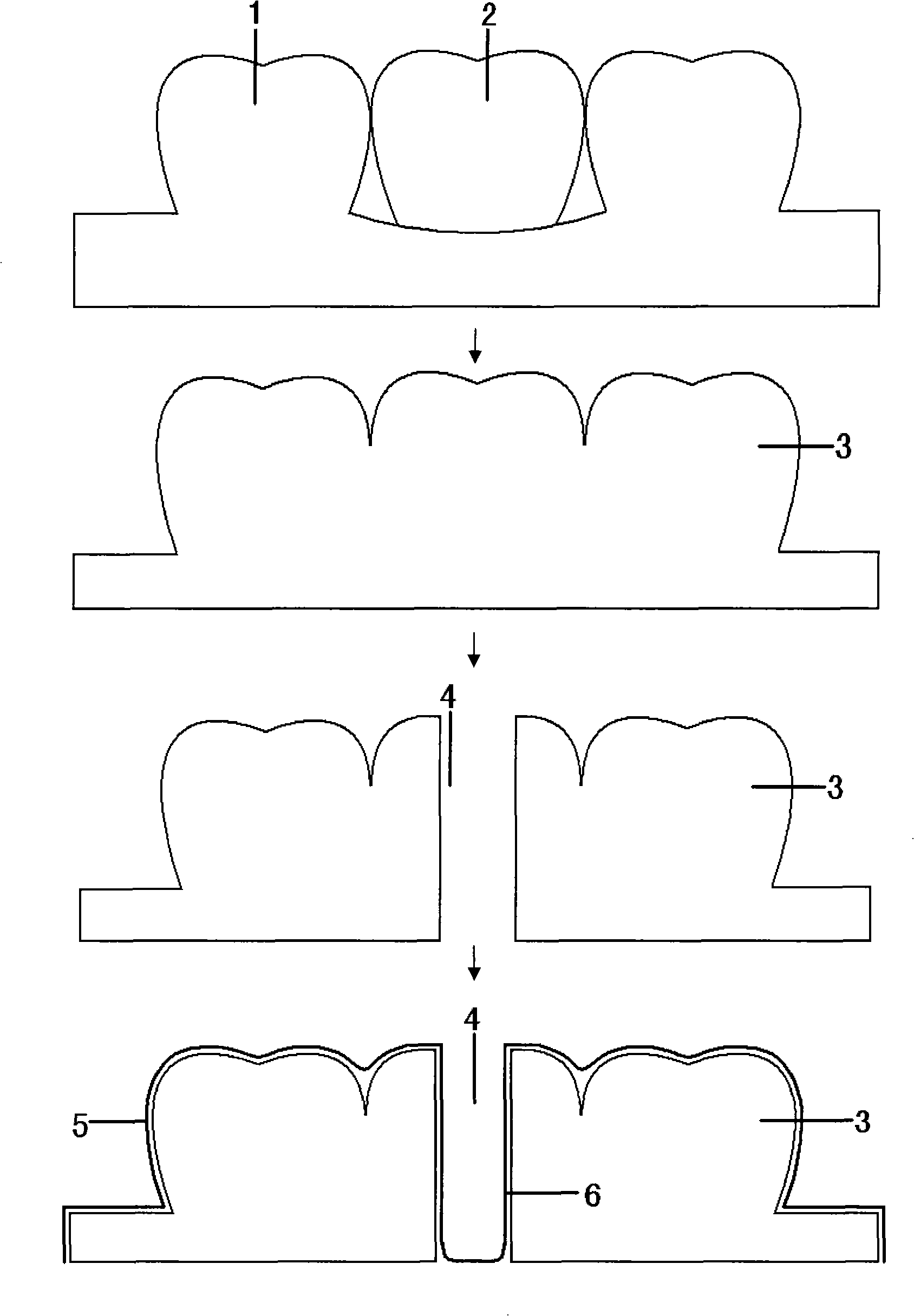

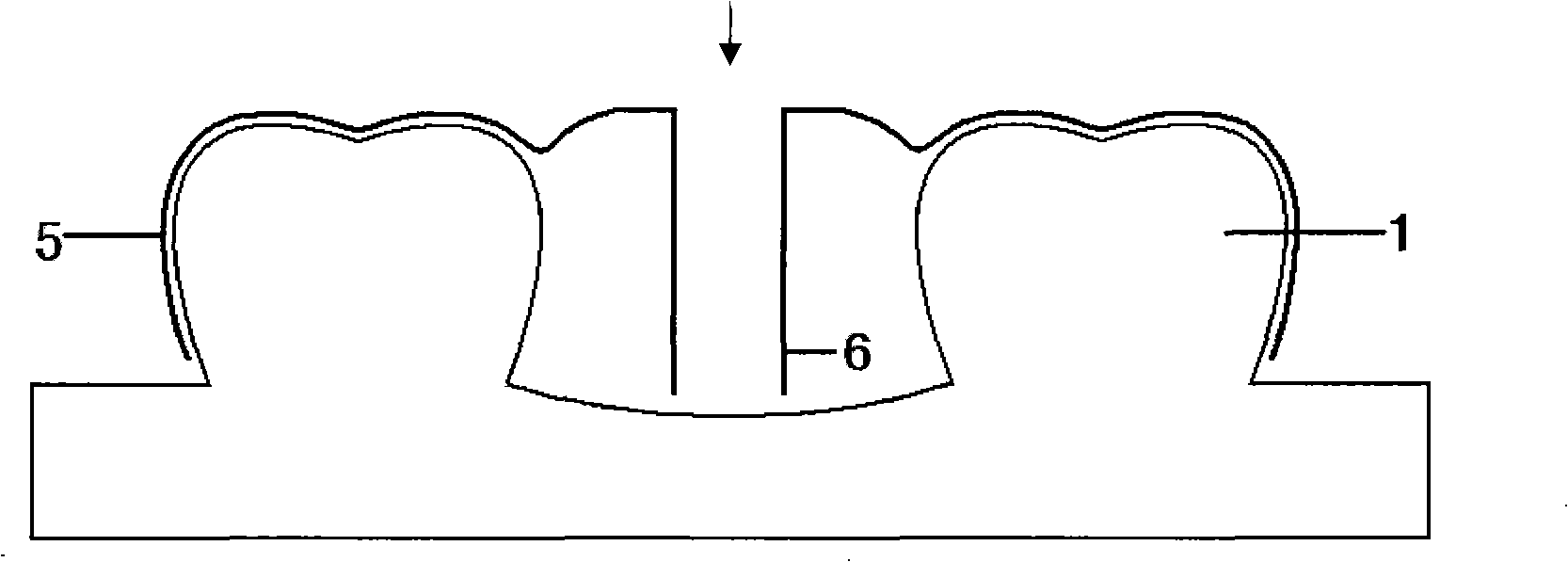

[0019] Embodiment 1: Taking the loss of the lower left first molar as an example, the implementation method of the present invention will be described in detail.

[0020] (1) In the edentulous area of the patient's plaster model-1, use a wax pile to mold a wax tooth 2 that conforms to the shape of the lower left first molar;

[0021] (2) the gypsum with wax teeth 2 is molded into model 2 3 which is all plaster, and its model base can not be too thick;

[0022] (3) According to the position of the lower left first molar and the shape of the alveolar bone, determine the insertion path of the implant screw;

[0023] (4) Use a split drill to drill a hole downward from the occlusal surface of the lower left first molar on the model 2 3, so that the hole 4 connects with the entire model. The position, diameter and direction of the hole 4 are consistent with the direction of the implant nail to be implanted. conform to;

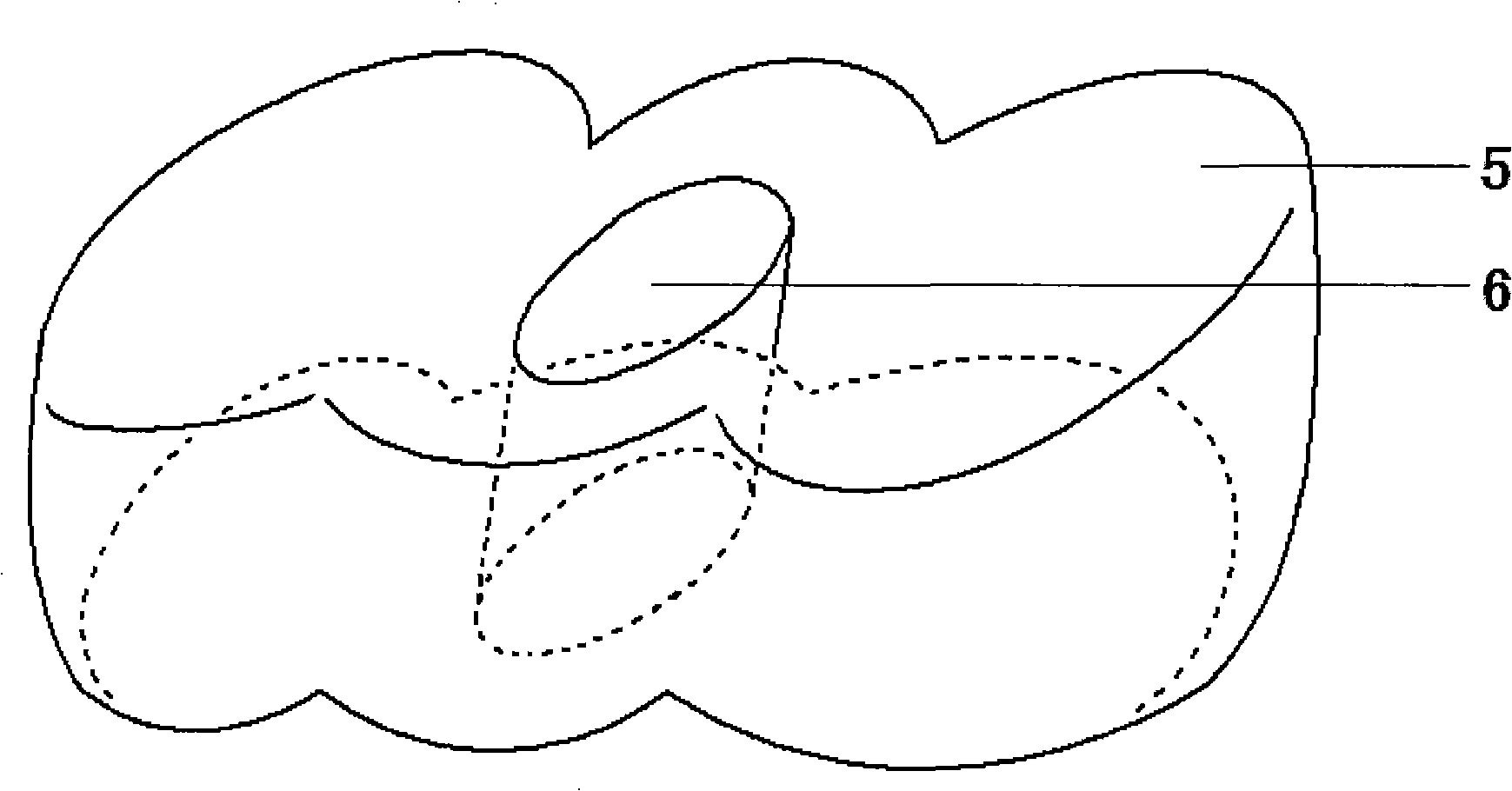

[0024] (5) Put the holed model 2 3 in the vacuum laminatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com