High-voltage electrical connector with visual indicator

A technology of electrical connectors and indicators, which is applied in the direction of connection, parts of connection devices, devices for preventing wrong connections, etc., and can solve problems such as difficult to determine that plugs and sockets are connected together

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

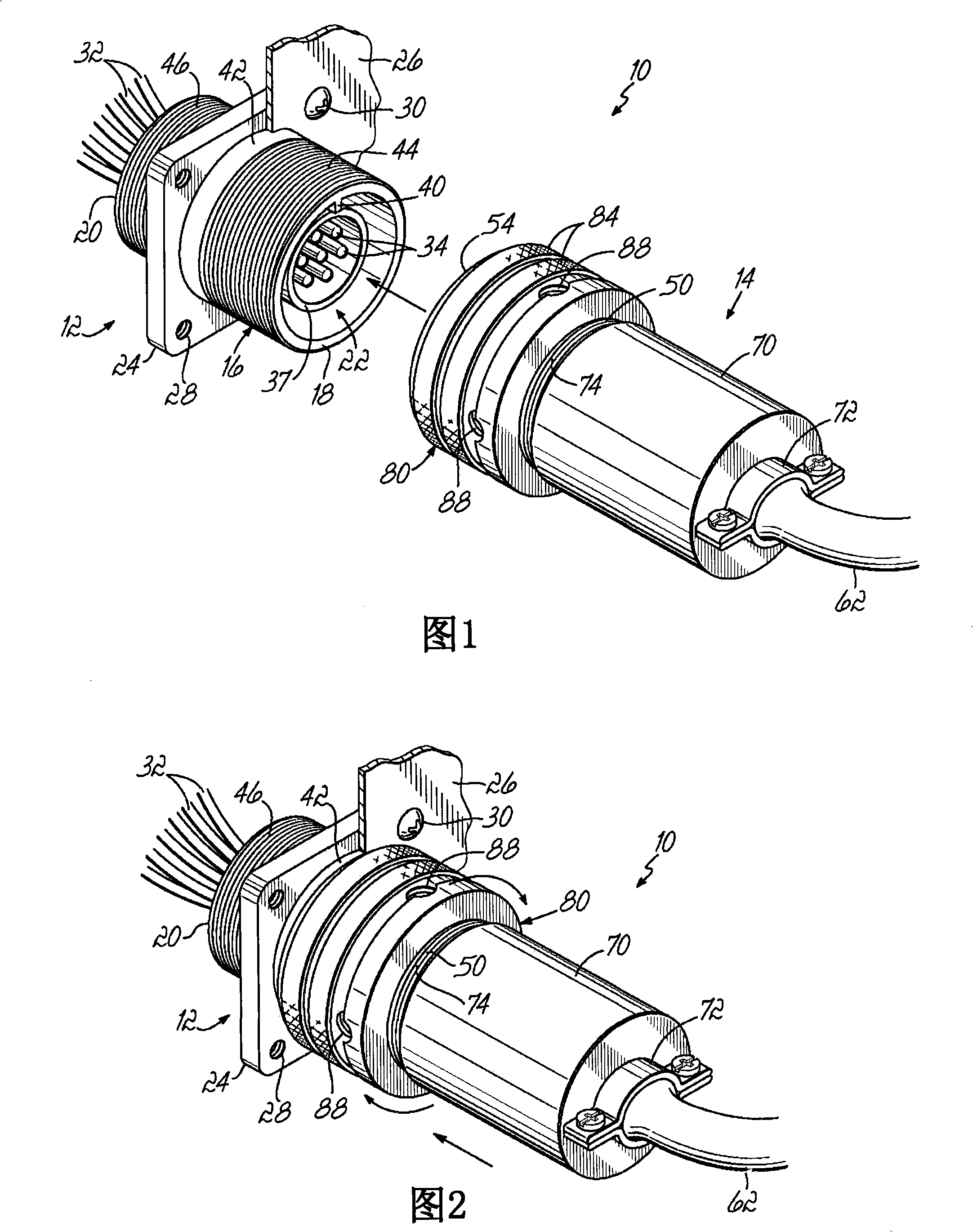

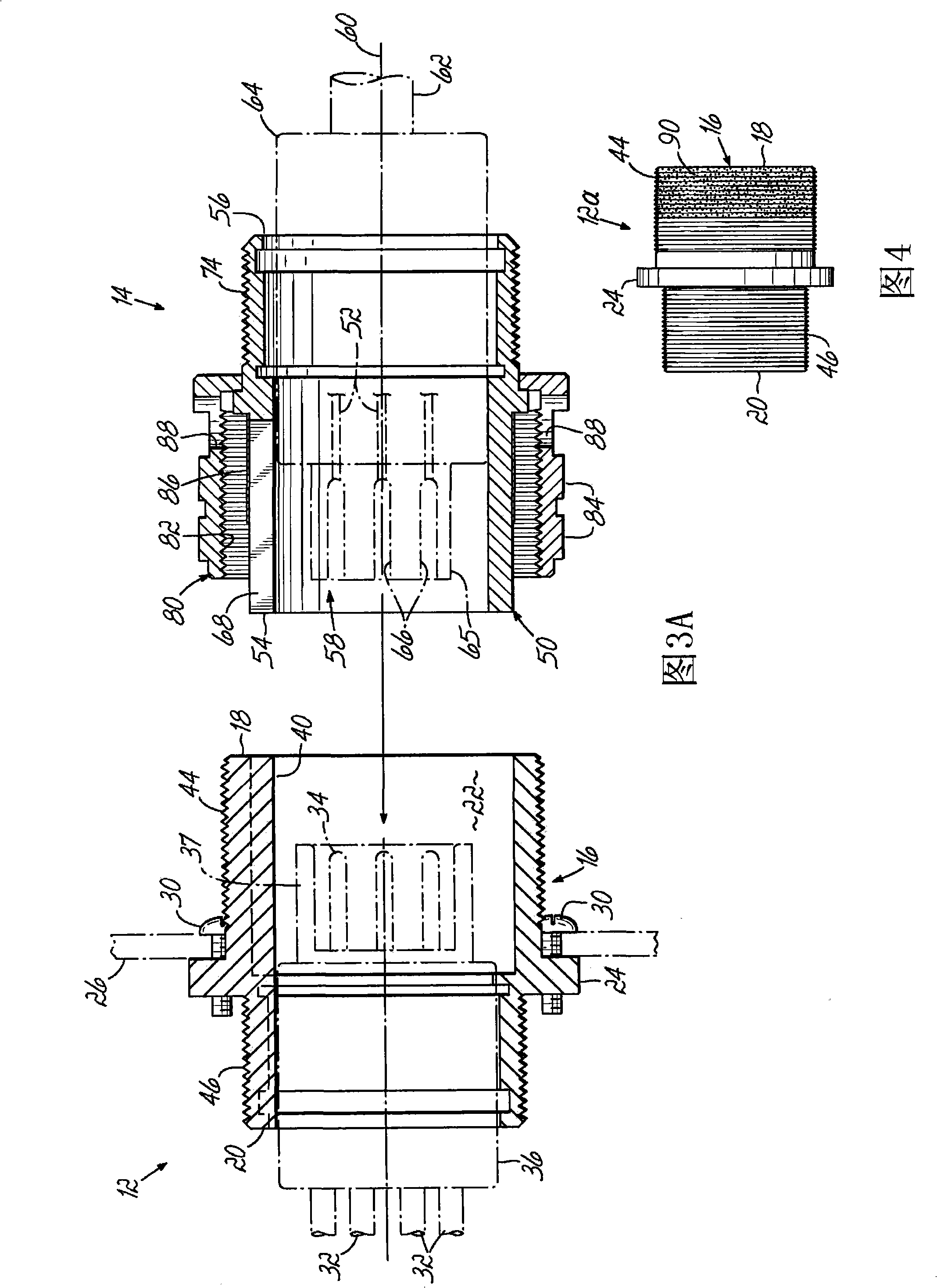

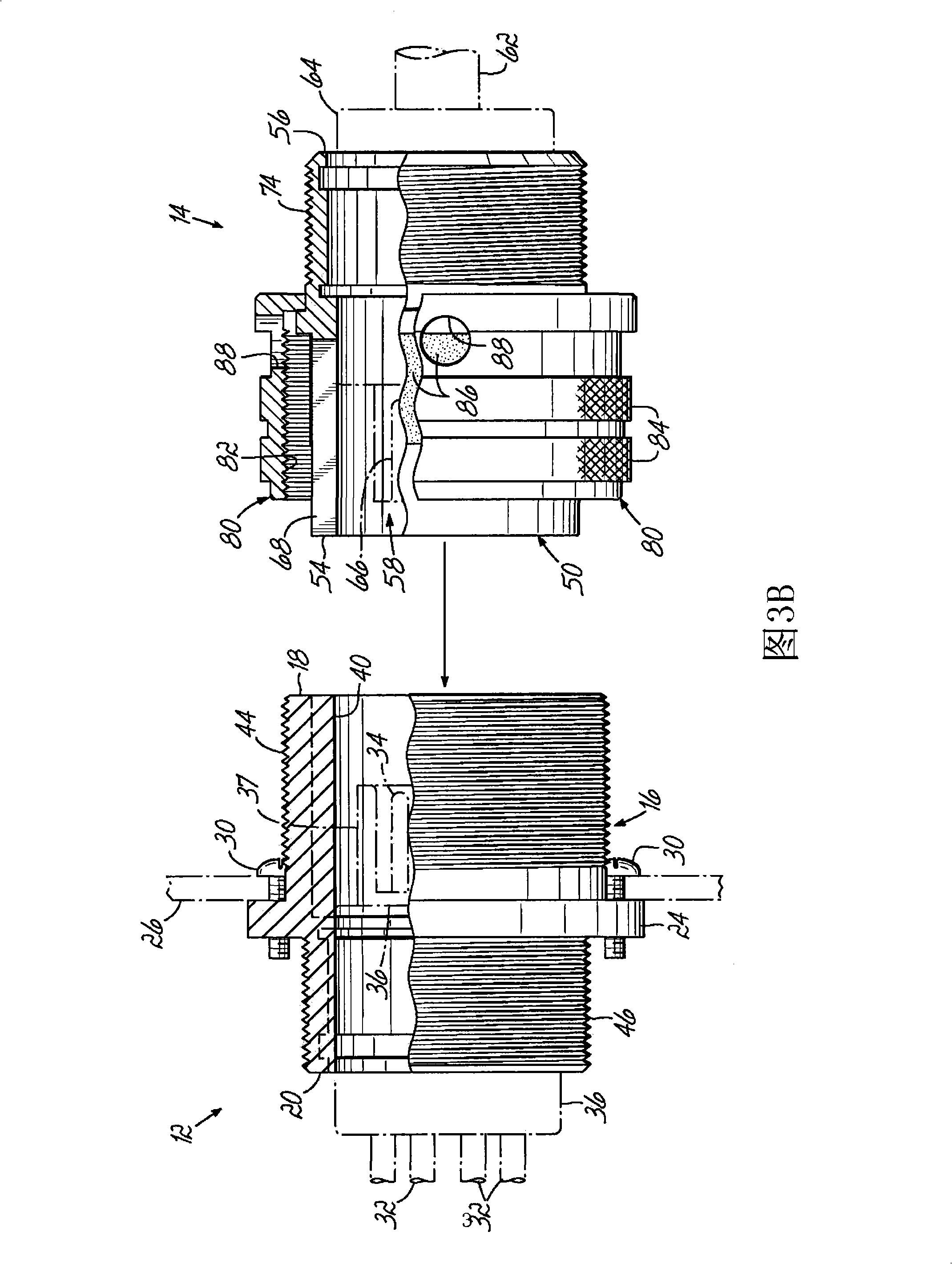

[0016] 1 and 3A depict an exemplary electrical connector 10 in accordance with the present invention. The electrical connector 10 includes a receptacle 12 and a plug 14 that can be selectively coupled together to provide a reliable electrical connection. The receptacle 12 includes a generally tubular housing 16 having a first end 18 , a second end 20 and an axial bore 22 extending between the first end 18 and the second end 20 . At a location intermediate the first end 18 and the second end 20, a mounting flange 24 extends radially outward from the housing 16 for securing the receptacle housing 16 to a bulkhead 26 of the article of electrical component. Holes 28 are provided in the mounting flange 24 for securing the receptacle 12 to the bulkhead 26 using screws 30 or other fasteners.

[0017] Wires 32 from the electrical components extend from the second end 20 into the bore 22 and connect to one or more electrical contacts 34 located within the bore 22 of the receptacle hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com