Low-grade fuel single prewarming and thermal storage type energy-saving boiler

A regenerative, low calorific value technology, applied in the field of boilers, can solve the problems of uneven temperature distribution in the combustion chamber, affecting the life of the furnace body, and high exhaust gas temperature, eliminating local high temperature areas, improving the life of the furnace, and increasing the combustion temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

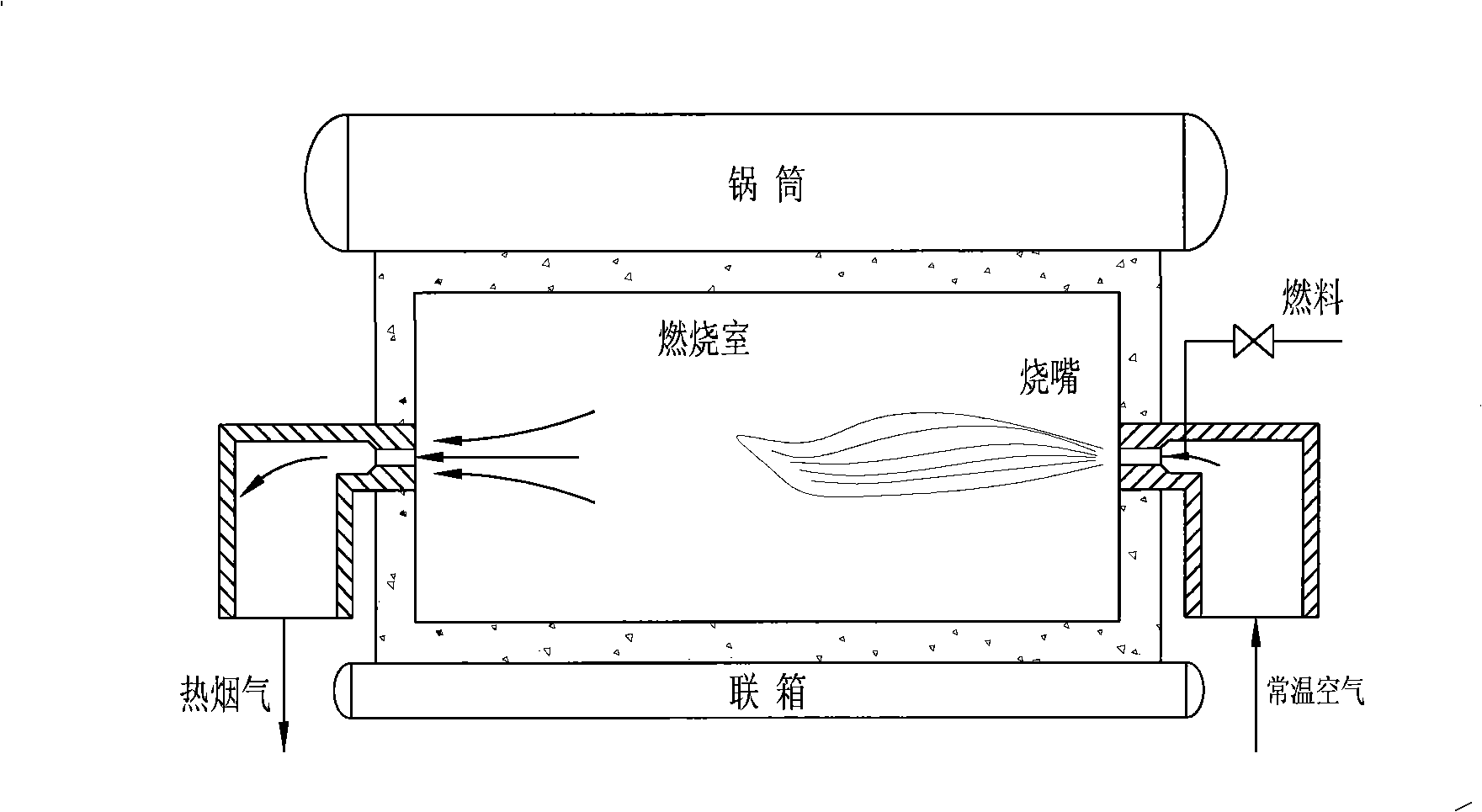

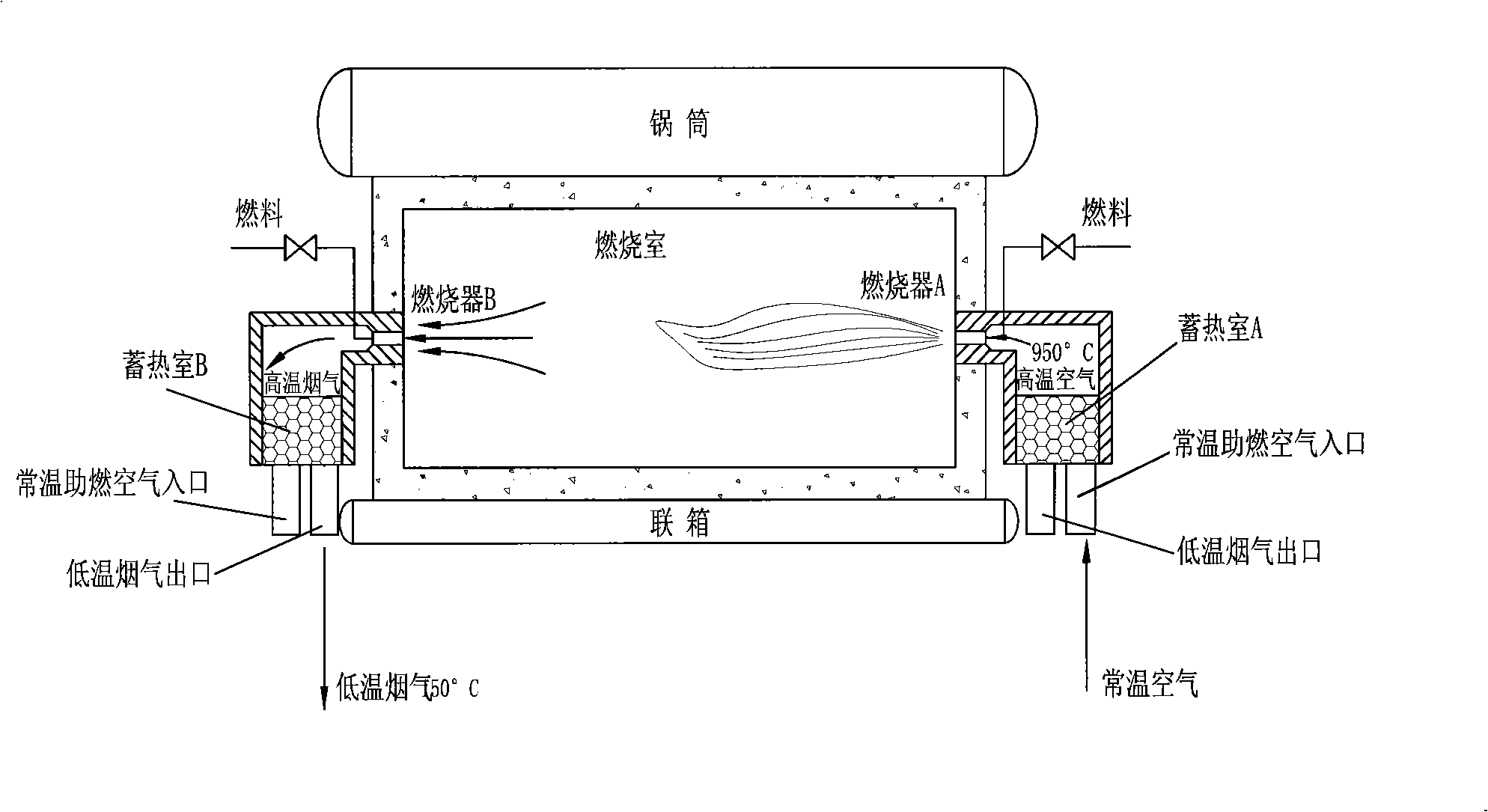

[0011] The low calorific value fuel single preheating regenerative energy-saving boiler of the present invention, its preferred specific implementation is as follows figure 2 As shown, including the furnace body, the interior of the furnace body constitutes a combustion chamber, and burners are installed on the wall of the furnace body. The furnace body is equipped with at least two burners, and multiple burners can be provided. Among the plurality of burners, every two burners are a pair, and the burners are periodically switched to each other. 1, 2, 3, 4 pairs of burners can be set, and other numbers can also be used as required.

[0012] The burner is provided with a high-temperature combustion-supporting air inlet and a fuel injection inlet, wherein the high-temperature combustion-supporting air inlet is used as a high-temperature flue gas outlet when the burner stops burning. Specifically, when the burner is burning, the high-temperature combustion-supporting air inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com