Gas/ solid two-phase composite gyration basic method and device

A reference device and reference technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems that cannot be used for large or super large loads, the improvement effect of radial vibration is not significant, large time constants and transition processes, etc. Achieve the effects of avoiding dry friction, protecting against damage, and having a large coefficient of static friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

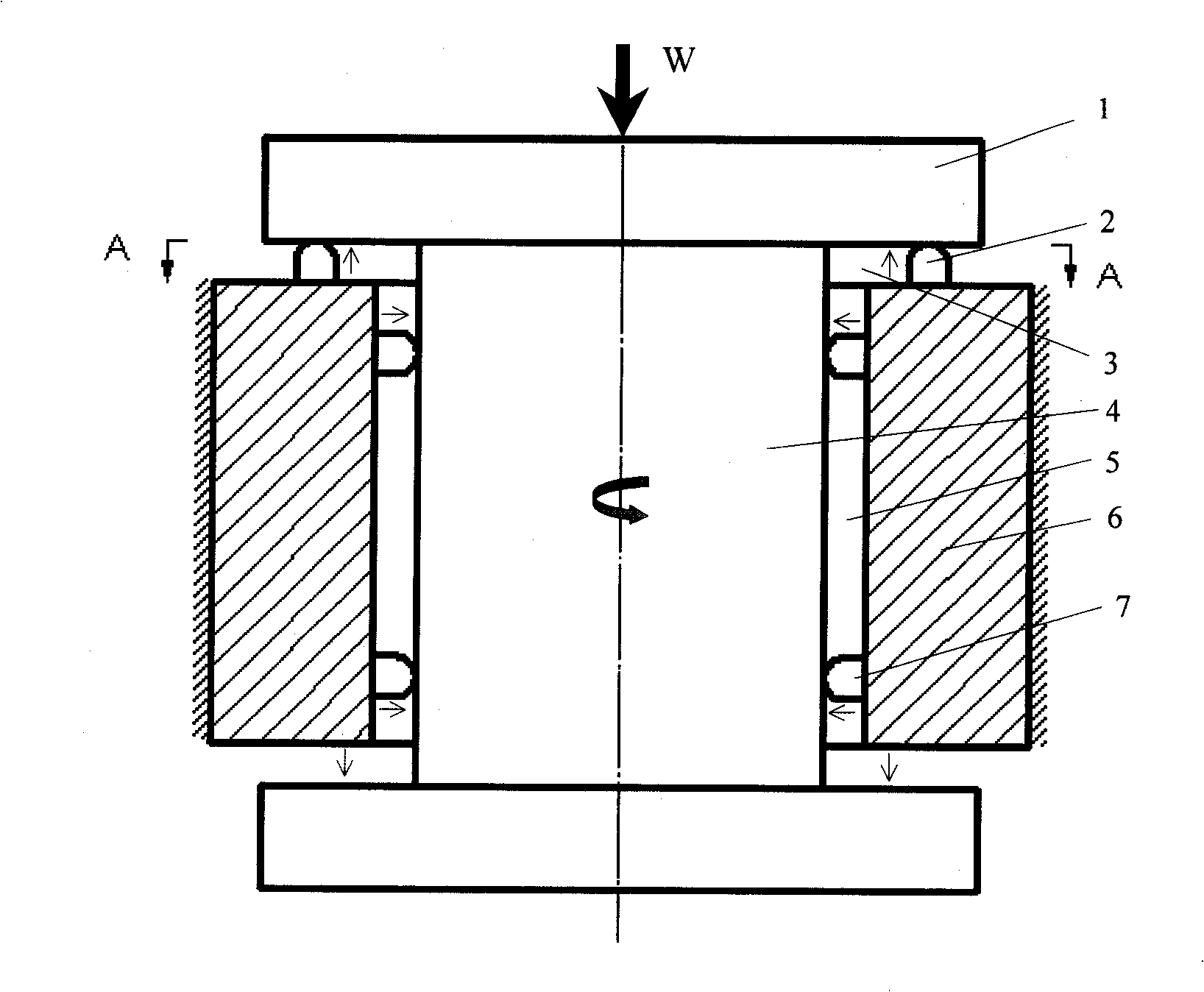

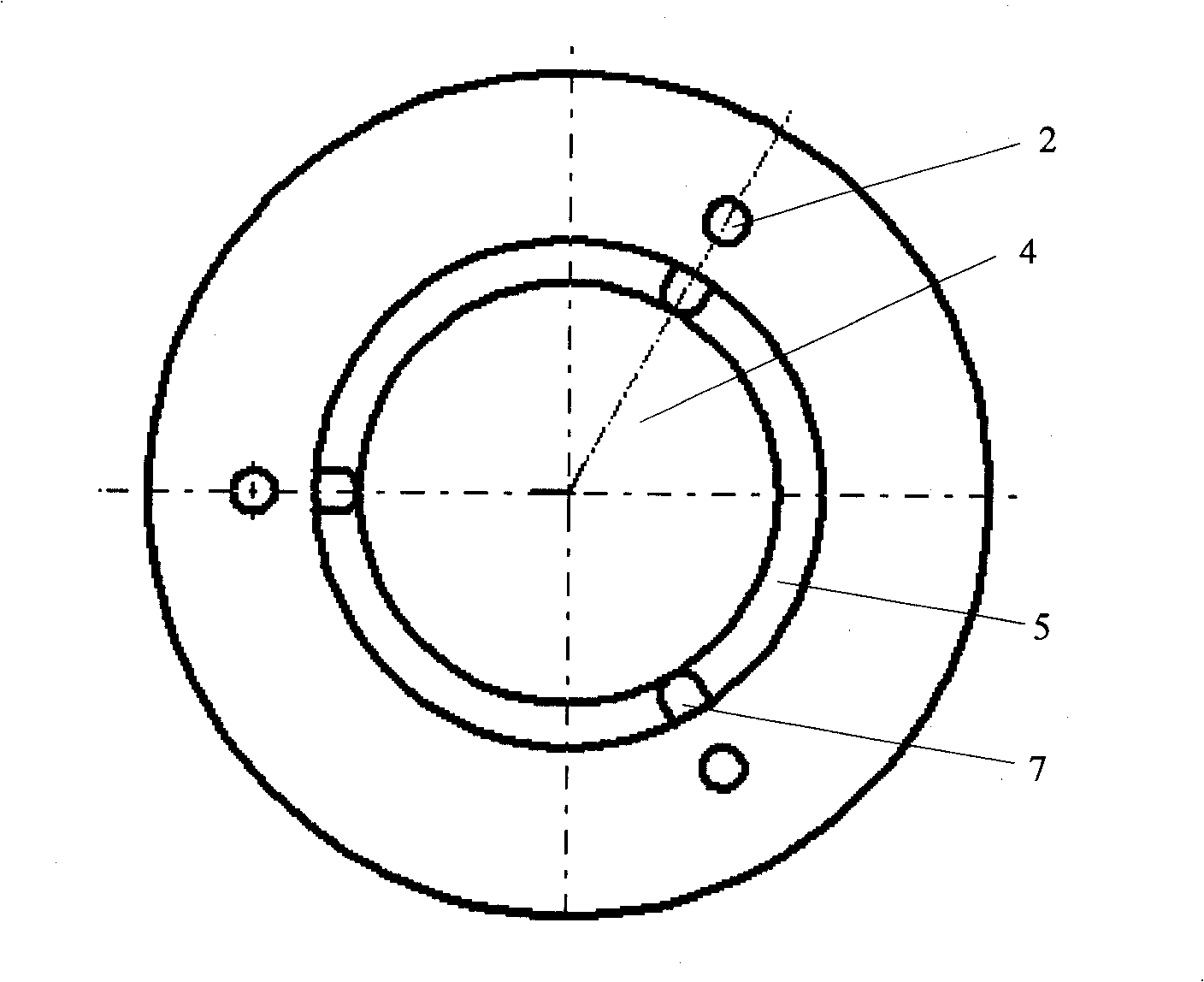

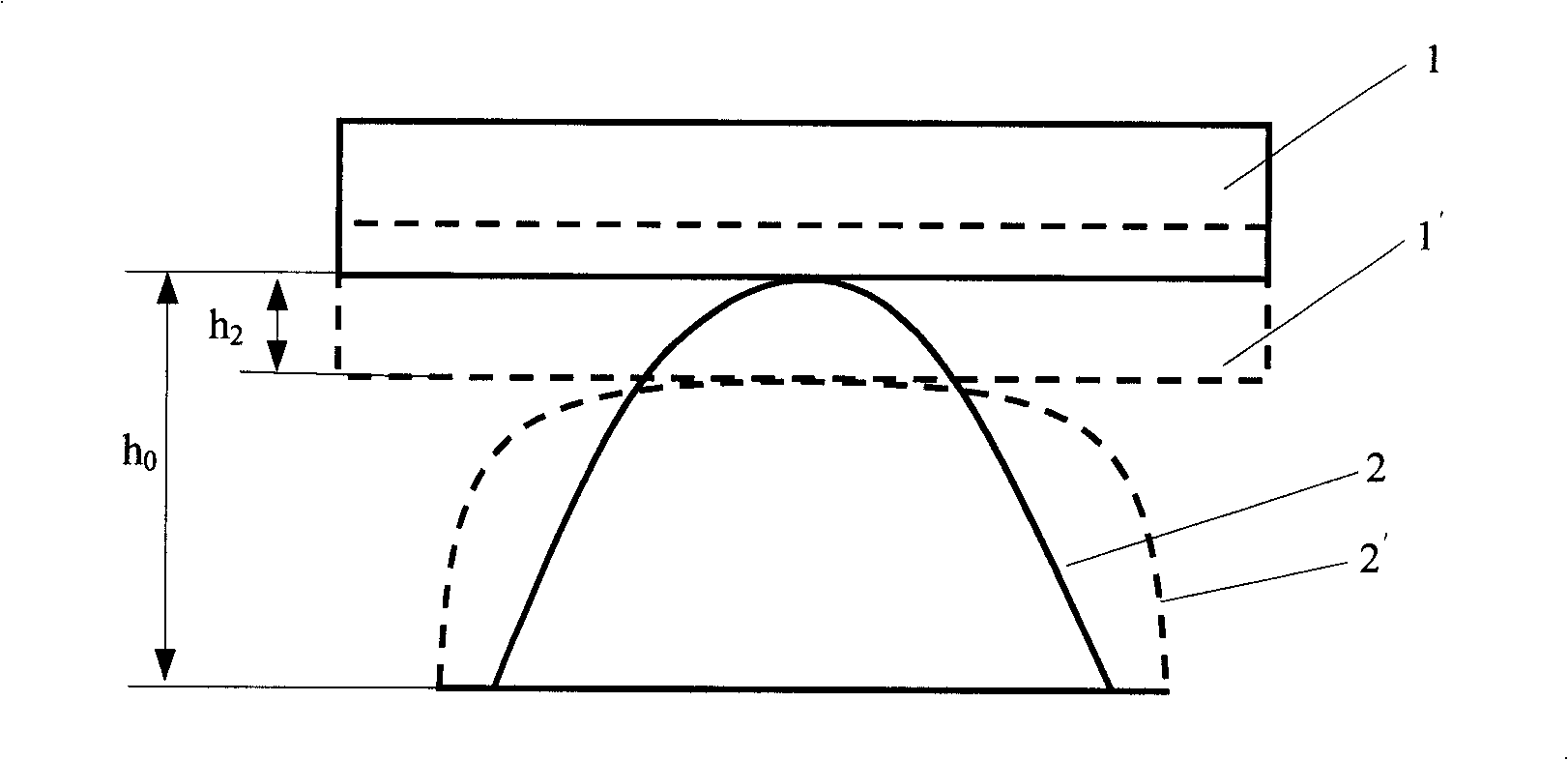

[0029] Such as figure 1 As shown, in order to overcome the problems of low axial stiffness and poor bearing capacity of the air-floating shafting system, the method of applying solid support in the axial thrust gas film 3 is adopted, and the large stiffness and high load-bearing characteristics of the solid support are compared with the gas bearing. Composite to improve the total bearing capacity of the air bearing shafting. To optimize the design of the axial support, the specific design principles can be determined according to the actual use conditions. In this embodiment, when the axial air film stiffness reaches the maximum, the gas / solid two-phase composite support just balances the load weight as the design criterion. It is known that the composite slewing benchmark to be designed can bear a load weight of W 0 , the air film thickness between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com