Silicon oil fan clutch

A clutch and silicone oil technology, applied in the direction of machine/engine, coolant flow control, engine components, etc., can solve the problems of limited working temperature range, low control precision, single control element, etc., and achieve wide temperature control range and control element Various effects with high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

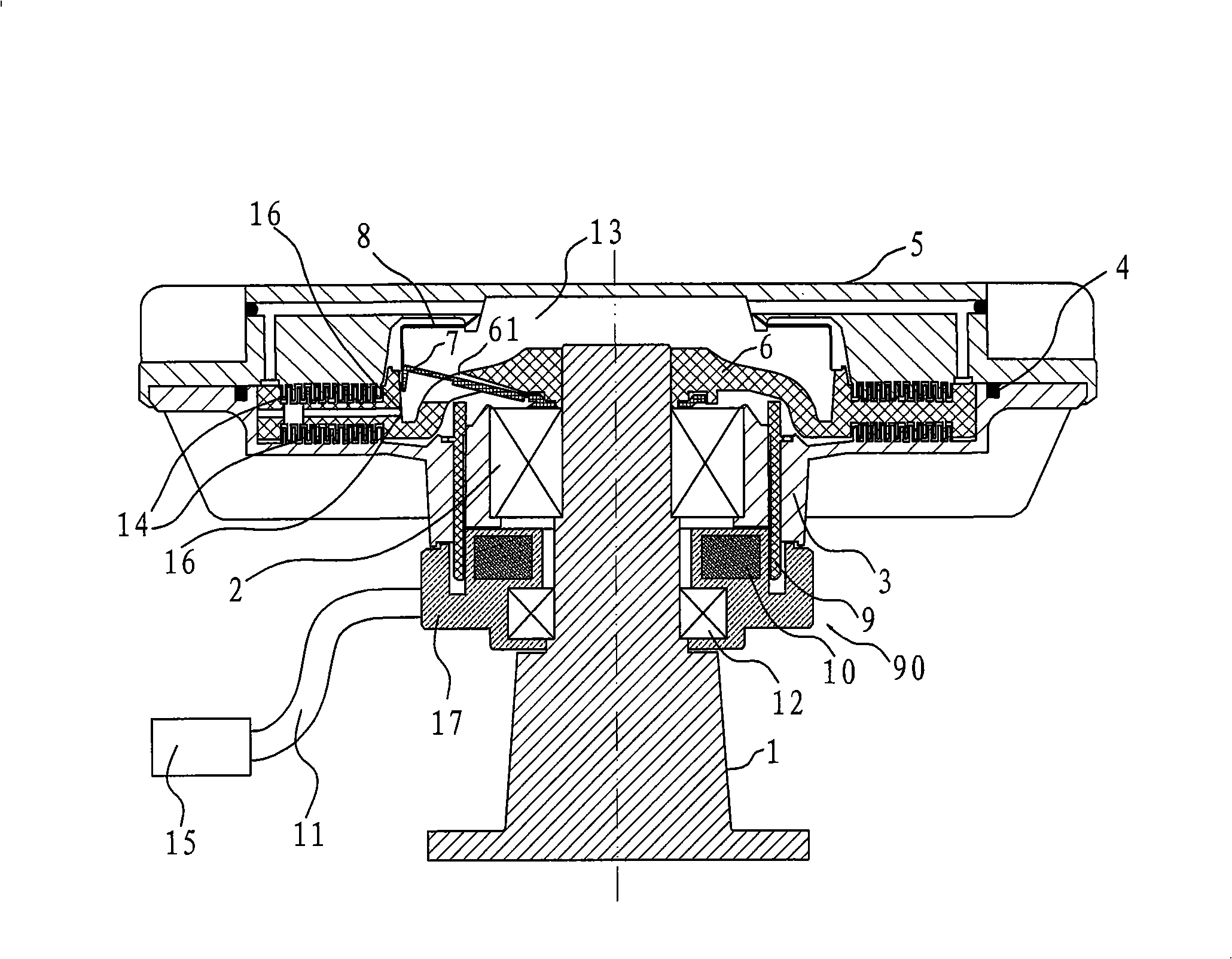

[0020] Example: Reference figure 1 with figure 2 shown.

[0021] The fan silicone oil clutch in this embodiment includes a driving shaft 1, a housing bearing 2, a housing 3, a front cover 5, a driving plate 6, a valve plate 7, an oil storage cover 8, an electromagnet 90 and an electromagnet bearing 12 . The housing 3 is inserted on the driving shaft 1 through a housing bearing 2 .

[0022] The drive shaft 1 is fixed in the middle of the housing 3 through the housing bearing 2, and the sealing ring 4 is fixedly connected between the front cover 5 and the housing 3; Engagement cavity 14; valve plate 7 has elasticity, one end of valve plate 7 is inlaid on active plate 6, and the other end is a free end that can open and close oil storage hole 16. The active plate 6 is provided with a limiting hole 61 for limiting the valve plate 7 .

[0023] The oil storage cover 8 is fixedly connected with the active plate 6 to form an oil storage chamber 13, and there is silicone oil in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com